The characterization of the pore-fracture structure (PFS) and its evolution during the mining process is crucial for preventing gas explosions and improving gas extraction efficiency.

In this study, a mechanical testing system combined with high-precision visual nuclear magnetic resonance equipment was used to directly capture the evolution of PFS in coal samples under mining stress conditions. Based on experimental results of PFS under different stress states, a fractional derivative model was established to describe the relationship between stress and porosity.

The results show that with the increase of triaxial stress, the content of adsorbed pore initially increases rapidly, then increases slowly or remains constant; the content of seepage pores and fractures (SPF) initially decreases, then increases; the compressibility coefficient of SPF decreases with the increase of triaxial stress.

The fractional derivative model can accurately describe the stress sensitivity of SPF in the pre-peak stage, providing a new method for accurately describing the permeability characteristics of coal reservoirs.

The formation of coal generates a large amount of natural gas, which is a major cause of disasters such as gas explosions and coal and gas outbursts, but it is also an efficient clean energy.

The pore-fracture structure (PFS) in coal provides storage space and flow channels for natural gas; it directly affects the gas permeability characteristics, which in turn affects coal mine production and safety.

Therefore, accurately describing the stress sensitivity of PFS in coal and its effect on permeability is essential for preventing gas outbursts and improving gas extraction efficiency.

In experimental studies, many testing methods can be used to describe PFS in coal samples, such as high-pressure mercury injection and low-temperature nitrogen adsorption. However, they cannot be performed during loading, and these methods only provide PFS characteristics before and after loading.

X-ray micro-computed tomography can achieve real-time scanning during triaxial loading, but due to the limited measurement range, it can only obtain data on large pores and fractures.

Scanning electron microscopy has a strong ability to observe local conditions of coal samples, but it does not provide sufficient overall characteristics.

Acoustic emission detection is simple and effective, but it is easily affected by other noises.

Compared to these methods, nuclear magnetic resonance (NMR) offers the advantages of being fast, comprehensive, and non-destructive. Therefore, many researchers use NMR to study the evolution of PFS in coal.

In this study, a pure titanium loading chamber and ceramic loading head were used for triaxial loading tests, and online NMR measurements were conducted during the triaxial loading process.

The successful combination of the mechanical testing system and high-precision visual NMR equipment promoted the application of NMR technology in engineering mechanics.

By using the conceptual model of fractures and seepage pores, the permeability evolution mechanism under mining stress was revealed. A fractional derivative model was established to describe the stress sensitivity of seepage pores and fractures (SPFs) before the peak compression stage, providing a new method for accurately describing the permeability characteristics of coal reservoirs.

The test samples were obtained from a coal mine in Yulin, Guangxi. The selected coal was buried at a depth of approximately 300 meters, with in-situ stress around 10 MPa. The coal blocks were drilled, cut, and polished, and processed into six cylindrical samples with a height of 50 mm and a diameter of 25 mm. Three complete coal samples were selected and sent to the laboratory for the following experiments. The physical characteristics of the samples are shown in Table 1.

Table 1 Sample Basic Information

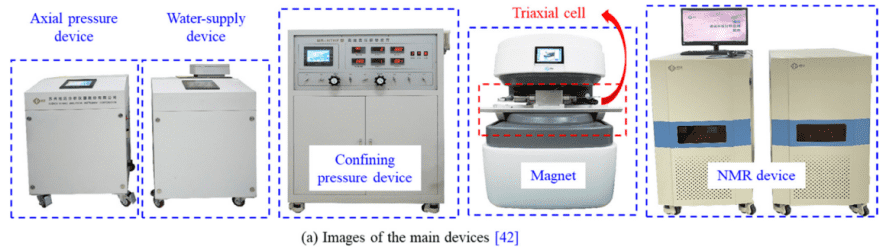

To capture and describe the evolution of PFS in coal samples under mining stress, we used an online observation and testing system combining a mechanical testing system with high-precision visual NMR equipment.

The NMR measurements were performed using the MacroMR12-150H instrument (manufactured by Suzhou Niumai Analytical Instrument Co., Ltd.).

The system consists of modules such as axial pressure, water supply, confining pressure, magnet, triaxial battery, and data collection. See Figure 1.

Figure 1 Online NMR Triaxial Loading Test System

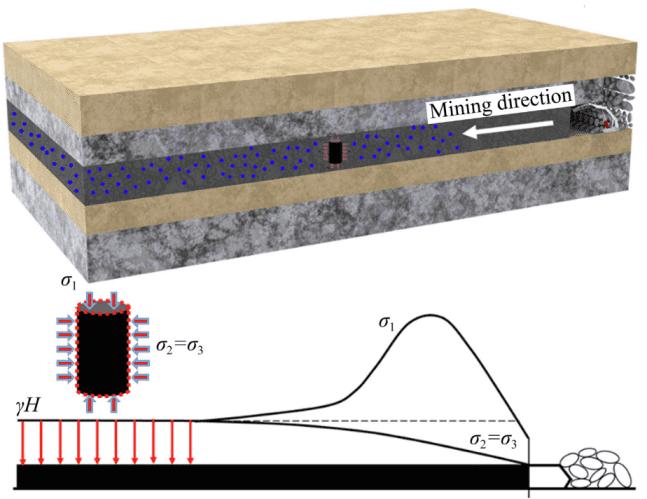

During coal mining, the coal undergoes a complete dynamic evolution from in-situ rock stress to increased vertical stress and slowly decreasing horizontal stress (Figure 2), resulting in changes to the coal’s PFS and permeability.

Thus, the in-situ NMR experiments on the coal samples were conducted under conditions of increasing axial stress and decreasing confining pressure. NMR imaging (NMRI) and T2 tests were conducted in real-time according to the stress path shown in the figure, simulating the coal samples under different stress states.

Figure 2 Triaxial Stress Diagram of Coal in Mining

The specific experimental steps were as follows:

1. Dry the sample at a constant temperature of 80°C for at least 24 hours, and measure the dry weight; evacuate for 2 hours, apply a 15 MPa water pressure for 24 hours, and measure the wet weight.

2. Wrap the sample in a shrink tube and place it in the NMR equipment; apply a confining pressure at a rate of 2 MPa/min until 10 MPa, then apply a 2 MPa water pressure. Conduct T2 and NMRI tests.

3. Apply axial pressure at a rate of 2 MPa/min and unload the confining pressure at a rate of 0.25 MPa/min. Conduct T2 and NMRI tests after every 0.5 MPa unloading pressure.

4. After reaching the peak stress of the coal sample, conduct T2 and NMRI tests. Switch the axial loading mode to displacement control at a rate of 0.1 mm/min and unload the confining pressure at a rate of 0.25 MPa/min. Conduct T2 and NMRI tests after every 0.5 MPa confining pressure.

NMRI Evolution Characteristics

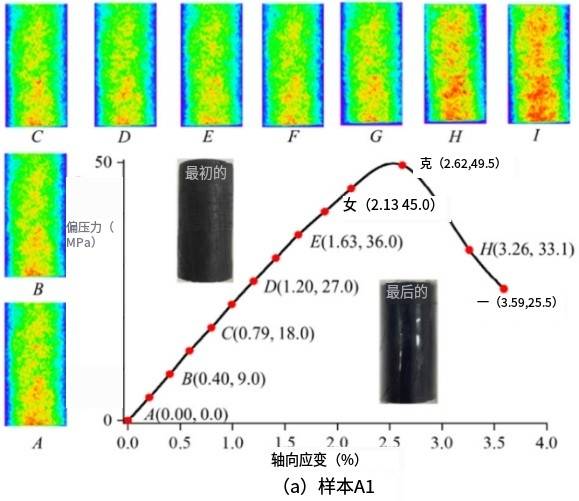

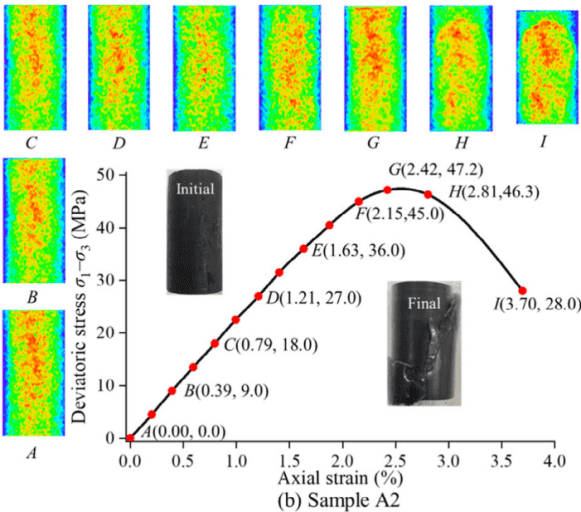

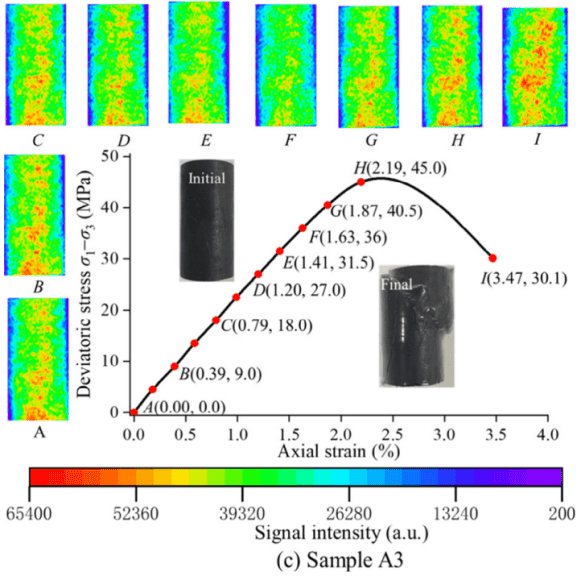

Figure 3 shows the stress characteristics and NMRI test results under mining pressure.

The peak strengths of the three samples were 49.5, 47.2, and 45 MPa, with maximum strains of 3.59%, 3.7%, and 3.47%, respectively.

The results of NMRI reflect the spatial distribution of water content in the samples during the loading process, with different colors representing different water contents, with warmer colors indicating higher water content.

Figure 3 2D Spatial Distribution of PFS in Coal Samples under Mining Pressure

According to the NMRI results, the water content in the lower part of samples A1 and A3 is higher than in the upper part. In contrast, sample A2 has higher water content in the upper part than in the lower part, indicating that the main spatial distribution of PFS in the test samples is uneven, which may explain their different peak stresses.

In the pre-peak stage, as the deviatoric stress increases, the water content in the samples initially decreases, then increases. The water content in the samples decreases in the early stage of loading for two main reasons: the compaction speed of the original PFS in the sample is higher than the generation rate of new pores; some new pores are not connected. Therefore, water cannot enter these parts, and the NMR signal cannot be detected.

Later, with the continuous increase of stress, a local PFS is formed and connected in the coal sample, causing the generation speed of PFS to exceed the compaction speed. As a result, the water content in the sample gradually increases.

In the post-peak stage, the water content in the coal sample increases rapidly because the bearing limit of the sample has been reached. Fractures and pores quickly connect to form large fractures, along with many secondary fractures.

T2 Spectrum and Stress Sensitivity:

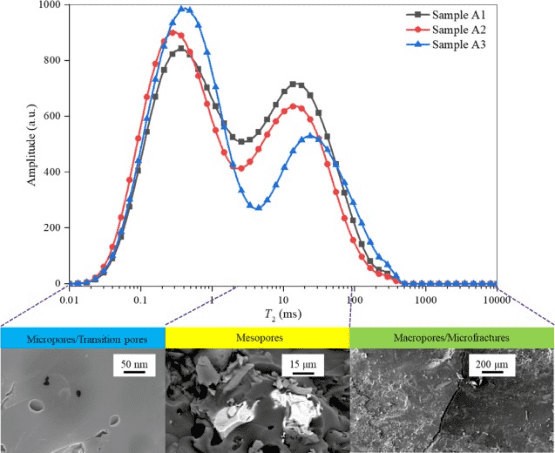

Figure 4 shows the T2 spectrum of each coal sample under hydrostatic pressure. According to the traditional pore classification method, the left peak (T2<2.5 ms) corresponds to micropores and transitional pores, while the middle peak (2.5-100 ms) corresponds to large pores and fractures.

Micropores and transitional pores mainly affect the gas adsorption characteristics of coal, called adsorption pores (APs); medium pores, large pores, and microfractures mainly affect the permeability characteristics of coal, called seepage pores and fractures (SPFs).

In the initial state, the AP content of samples A1, A2, and A3 was 9.28%, 9.39%, and 9.82%, respectively, and the corresponding SPF content was 8.21%, 6.73%, and 6.01%.

Figure 4 Traditional Pore Classification

Stress Sensitivity of Pores in Three Samples

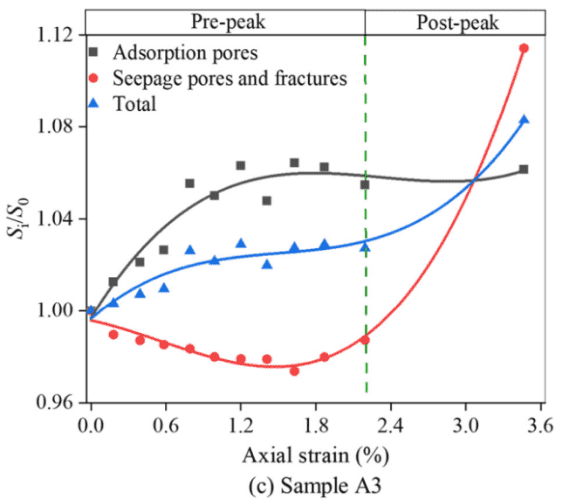

The AP content of samples A2 and A3 initially increases, then remains constant as strain increases. Sample A1’s AP content rapidly increases at first, then increases slowly with strain.

The SPF content initially decreases, then increases with strain, with the cutoff point occurring at 80% to 91% of peak stress, consistent with the NMRI results.

Since the AP content and its variation range are larger than that of SPF, the total PFS is mainly controlled by the AP content in the pre-peak stage. Total PFS initially increases rapidly, then gradually increases. In the later post-peak stage, SPF content and total PFS increase rapidly.

Figure 5 T2 Spectrum Area Ratio of Specific Pores under Different Axial Strain

The evolution of AP during the loading process is affected by many factors. Under deviatoric stress, water in some large pores may form a thin film on the mineral surface. The relaxation time of water in the film is very short, so it superimposes on the pore signal, leading to an overestimation of the pore content.

Thus, the evolution of AP can be roughly divided into two stages: rapid increase, followed by gradual increase or stabilization.

Under low-stress conditions, it is difficult to compress AP, and some SPFs are compressed into APs. In addition, some water films are produced, and the AP content increases rapidly. As the deviatoric stress increases, APs begin to compress, causing a decrease in the AP content. At the same time, some SPFs are compressed into APs, and new water films are produced, increasing the AP content. However, the wettability and compressible SPF content of different samples are different, leading to the slow increase or stabilization of the AP content during this stage.

The changes in SPF content during loading are divided into two stages: initial decrease and subsequent increase.

Under the action of stress, large fractures and pores are compressed in the early loading stage, and near the peak stress, new fractures are generated, and some small pores are penetrated, forming large pores.

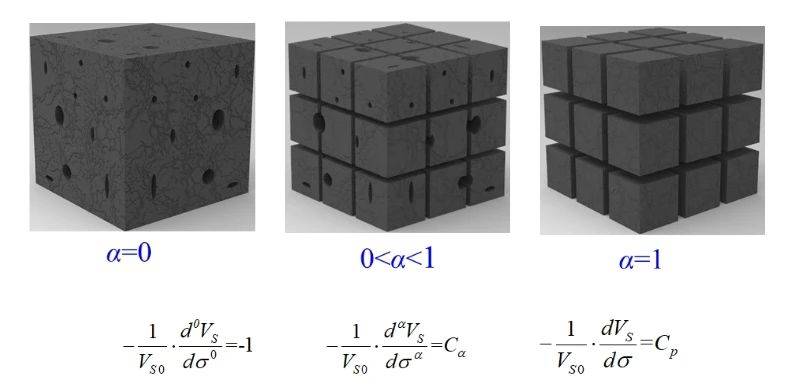

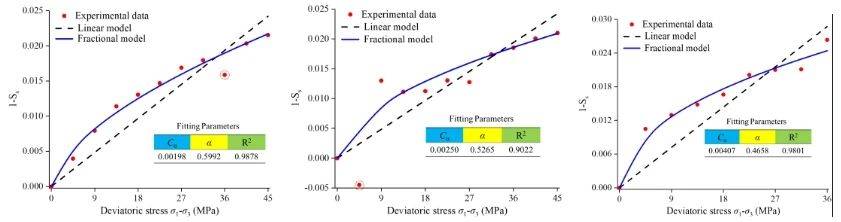

NMR can measure the content of pores of different sizes. Since AP and SPF contents mainly determine the gas adsorption capacity and permeability of coal, it is necessary to calculate the compressibility of SPFs during the compression process of coal samples. Thus, a compressibility model for SPFs was established, and it was extended to the fractional derivative permeability model, as shown below:

When α=0, the sample contains only disconnected pores, and the volume of seepage pores is proportional to the zeroth-order derivative of deviatoric stress;

When 0<α<1, the coal sample contains both well-connected seepage pores and poorly connected pores, described using fractional derivatives;

When α=1, the sample contains only well-connected fractures, and the volume of seepage pores is proportional to the first-order derivative of deviatoric stress;

Through fitting the experimental data, good fitting results were obtained. This shows that it is feasible to re-establish the relationship between stress increment and seepage pore volume increment during pre-peak compression, and the proposed fractional derivative model for seepage pore compression can well describe the experimental results of seepage pore compression in the pre-peak compression stage.

[1] Zhou H, Liu Z, Zhao J, et al. In-situ observation and modeling approach to evolution of pore-fracture structure in coal[J].International Journal of Mining Science and Technology: English Edition, 2023, 33(3):265-274.

Phone: 400-060-3233

After-sales: 400-060-3233

Back to Top