Nano-ion sensing materials that are fatigue-resistant and self-healing, like human skin, are crucial for extending the lifespan of soft electronics and robots. However, due to the ease of polymer chain breakage and crack propagation, most existing self-healing artificial nano-materials for skin, based on network reconstruction, have low fatigue thresholds.

This paper designs a fatigue-resistant, self-healable hybrid ionic skin, made from high-energy, self-repairing elastic nano-materials, resembling the self-healable nanofiber woven structure of human skin.

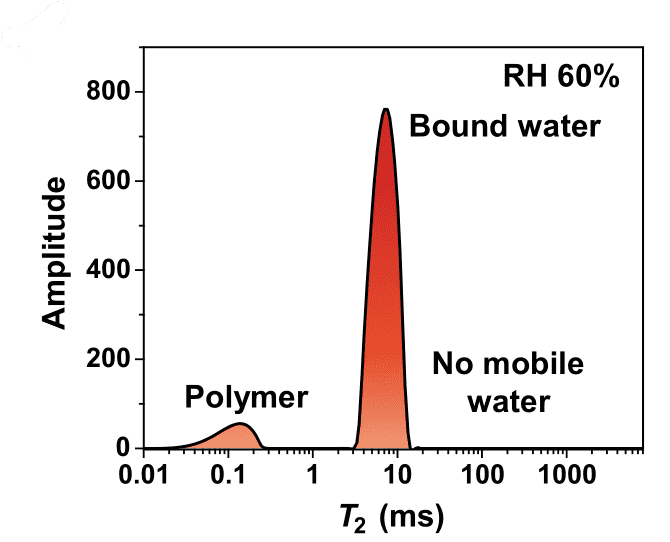

Low-field nuclear magnetic resonance (LF-NMR) technology provides valuable support in the performance testing and theoretical validation of this material: it allows for quick, non-destructive analysis of the state and quantity of water in the material.

Robust sensing materials are ideal for future human-machine interfaces and soft robotics, but they are challenging to achieve, especially when it is necessary to combine materials with mutually exclusive properties. These properties include conductivity, stretchability, softness, toughness, self-healability, and durability. For long-term performance, materials not only need to self-heal when damaged, but also resist crack propagation under fatigue loads.

Balancing self-healing and fatigue resistance is a challenging task for stretchable nano-materials for ionic skin (human skin analogs). Notably, most self-healing ionic skins are generated by introducing dynamic covalent or physical cross-linking into the ionic conductive network. This dynamic inter-chain design generally does not contribute to fatigue fracture resistance, as the low energy of the polymer chains makes them susceptible to crack propagation under repeated loading.

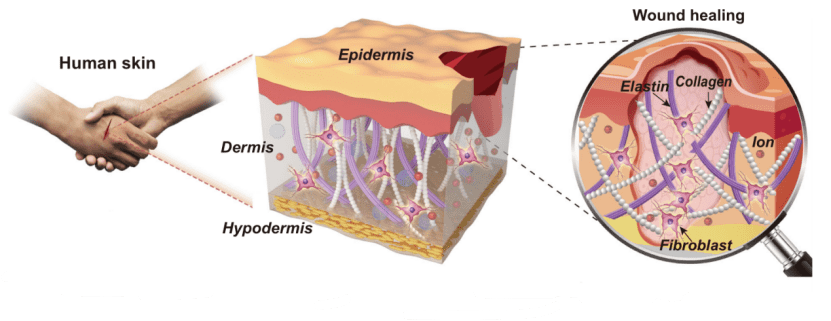

Related reports introduced swollen covalent network microspheres to reversibly entangle with linear networks, achieving both high fatigue resistance and self-healing. However, the resulting mechanical strength is relatively low due to the embedded intrinsic softness. In contrast, human skin effectively balances self-healing and fatigue resistance, thanks to its ion-rich and layered nanofiber-repairable structure, supported by a soft elastic matrix.

These two phases not only heal with the help of dermal fibroblasts on the wound but also give human skin high fracture toughness by fixing crack tips on the nanofibers. As a result, human skin can withstand certain tears and repeated deformations, enduring over one million cycles annually without fatigue.

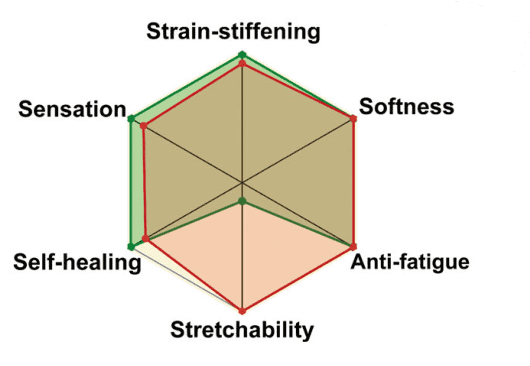

Fig. 1 Structure of Real Human Skin Tissue

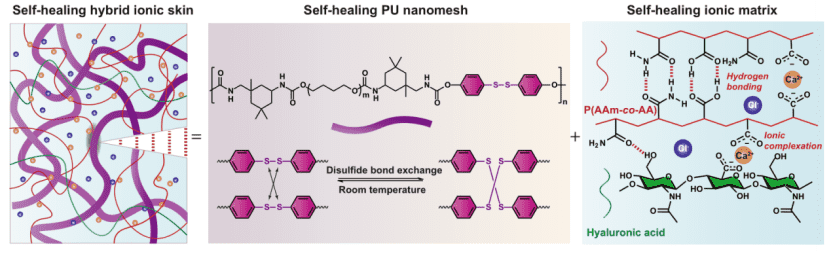

Inspired by the self-healable nanofiber structure of human skin, this paper designs a nano-sensing artificial ionic skin, embedding a high-energy self-healing elastic nanomesh scaffold into another self-healing soft ionic matrix. This hybrid design leads to ultra-high fracture energy and fatigue threshold, while maintaining self-healability, softness, stretchability, and strain-hardening response similar to real human skin.

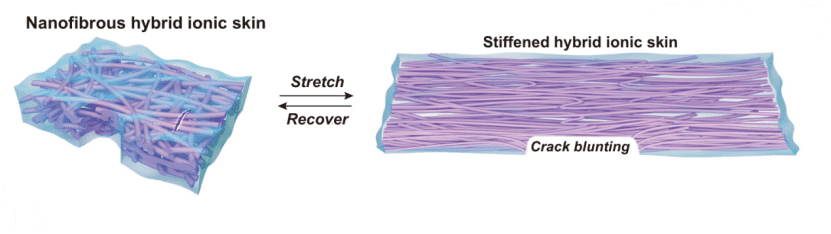

Fig. 2 Nano Artificial Sensing Ionic Skin Designed in this Study (1)

Fig. 3 Nano Artificial Sensing Ionic Skin Designed in this Study (2)

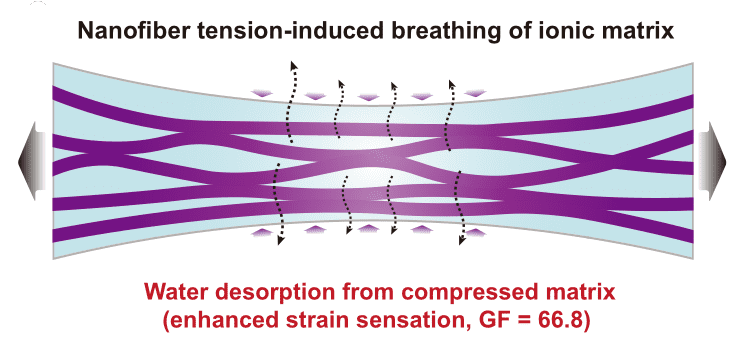

The tension-induced alignment of the nanofibers forces the hygroscopic ionic matrix to reversibly absorb moisture from the air, significantly enhancing the stretchability.

Fig. 4 Demonstration of Stretching Performance of Nano Artificial Sensing Ionic Skin

This paper reports on an artificial ionic skin that mimics or even surpasses human skin in several prominent sensory/mechanical characteristics (sensation, softness, stretchability, self-healing, strain hardening, fatigue resistance). Furthermore, the hybrid ionic skin is transparent, frost-resistant, environmentally stable, and adhesive, further enhancing its potential applications in various sensing scenarios.

Fig. 5 Comparison of Nano Artificial Sensing Ionic Skin with Real Human Skin Characteristics

In this study, the comparison between artificial ionic skin and real human skin characteristics shows that their properties are quite similar, or even exceed those of human skin. To achieve these conclusions, the researchers employed various techniques and designed numerous experimental test schemes from different angles.

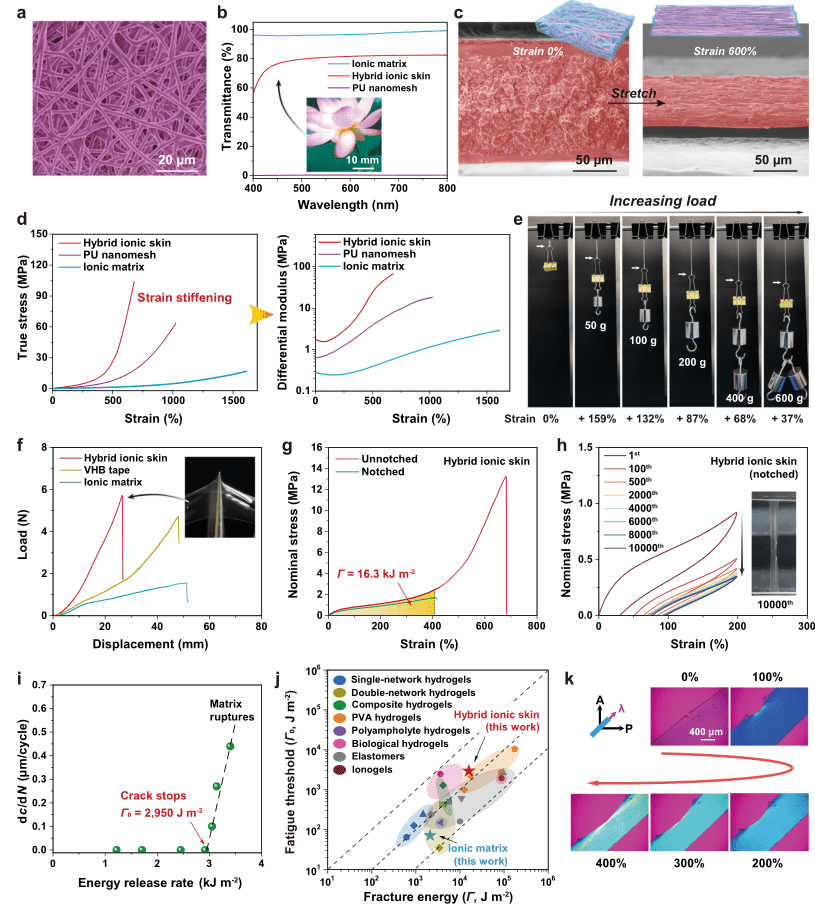

Fig. 6a shows the electron microscope scan results of the artificial ionic skin, where it can be observed that the artificial ionic skin is composed of a multi-layered, high-density nanomesh material;

Fig. 6b confirms that the artificial ionic skin has 80% light transmission;

Fig. 6c shows the cross-sectional electron microscope images of the artificial ionic skin before and after stretching, where the pre-stretching artificial ionic skin exhibits a sandwich-like structure, with a mesh structure in the middle and two thin layers of ionic matrix on the outside. After stretching, the three layers deform cooperatively without inter-layer delamination or fiber pull-out;

Fig. 6d shows the stress-strain curve, indicating that, compared to PU nanoweb and pure ionic matrix, the hybrid ionic skin rapidly hardens, meeting the required stretch resistance and contributing to a timely hardening response;

Fig. 6e verifies that the nonlinear strain-hardening behavior of the hybrid ionic skin has high repeatability in cyclic stretching tests. A small load of 50g immediately caused the elongation rate of the artificial ionic skin to become 159%, and as the load further increased to 600g, the increased elongation rate became smaller;

Fig. 6f shows the high puncture resistance, tear resistance, and fatigue resistance of the hybrid ionic skin, which outperforms the other two control samples (commercial tape and pure ionic matrix);

Additionally, there are stress-strain test curves (Fig. 6g); cyclic stretching test curves (Fig. 6h); fatigue threshold tests (Fig. 6j); and stretching to 400% POM test images (Fig. 6k).

Fig. 6 Experimental Results of Artificial Ionic Skin Characteristics from Different Techniques

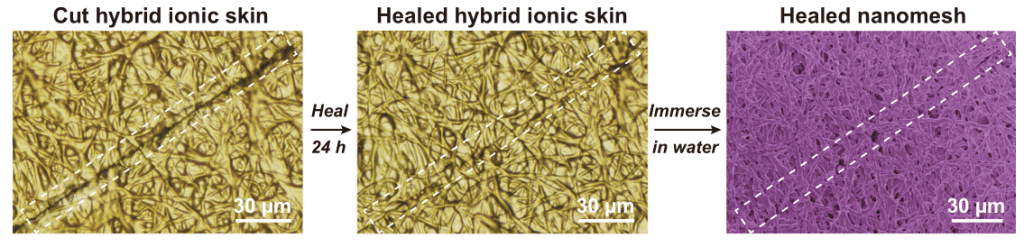

Here, we vividly demonstrate one of the most important characteristics of artificial ionic skin—its self-healing ability, similar to human skin.

Fig. 7 shows the artificial ionic skin being cut. The cutting marks are clearly visible in the electron microscope scan, but after 24 hours, a miraculous scene occurs: the cut marks visibly self-heal, and after washing the ionic matrix, further self-healing occurs, with the cut marks almost disappearing.

Fig. 7 Electron Microscope Scan of the Self-Healing Process of Artificial Ionic Skin

The powerful self-healing ability of the artificial ionic skin, along with its other human skin-like or even superior characteristics, is attributed to the multi-level, high-density nanomesh material structure, where the distribution and binding state of water within the material are crucial.

To study the distribution and binding state of water in the nanomesh material, low-field nuclear magnetic resonance (LF-NMR) technology was used for testing. Niumag’s LF-NMR technology offers advantages such as fast repeatability, high sensitivity, and pollution-free operation, enabling rapid and accurate measurement of the relaxation signals of water in the material, and effective analysis of the water-material binding state.

After testing with LF-NMR technology, as shown in Fig. 8, water in the artificial ionic skin exists entirely as bound water, which explains the frost resistance and other characteristics of the artificial ionic skin.

Fig. 8 Relaxation Test Results of Artificial Ionic Skin

[1] Wang J, Wu B, Wei P, et al. Fatigue-free artificial ionic skin toughened by self-healable elastic nanomesh[J]. Nature Communications.

Phone: 400-060-3233

After-sales: 400-060-3233

Back to Top