Artificial ground freezing technology is widely applied in various engineering fields, including mining, bridges, subways, tunnels, and emergency repairs, achieving favorable engineering outcomes. The freezing strength and freezing effects of artificial freezing technology have become a hot research topic. However, the relationship between freezing strength and unfrozen water content under extremely low temperatures has not been sufficiently studied. Therefore, this paper uses Nuclear Magnetic Resonance (NMR) technology to study the unfrozen water and compressive strength characteristics of soil under extreme low-temperature conditions from 0°C to -80°C. The applicability of a genetic algorithm-backpropagation (GA-BP) predictive model for forecasting unfrozen water at low temperatures is also discussed. The results indicate that at -80°C, a very small amount of unfrozen water remains, with a content of about 0.1%. The GA-BP model can be used to predict the unfrozen water content of soil under extremely low temperatures. The compressive strength of frozen soil is significantly influenced by temperature and unfrozen water content. The compressive strength is directly proportional to the absolute value of soil temperature. The relationship between compressive strength and unfrozen water content follows a power function. This study supplements the basic theory of extremely low-temperature frozen soil, quantifying the impact of unfrozen water content on the strength of frozen soil. It has significant implications for the stability of artificial freezing projects and can provide theoretical references for practical engineering.

The process of urbanization has accelerated the development of underground space, but during this process, a series of engineering problems have arisen, resulting in accidents involving casualties and property losses, significantly hindering project progress. Unlike traditional methods, ground freezing technology cools the soil evenly through artificial refrigeration. The water in the soil freezes into ice, forming frozen soil, which greatly enhances the overall strength of the strata, ensuring construction safety. Therefore, ground freezing technology is the optimal technique for preventing and controlling water hazards and deformation in soft, water-rich layers. In contrast, using dry ice to freeze the ground generates extremely low temperatures that have a strong freezing effect on the soil, altering the physical and mechanical properties of the soil and rock. Consequently, studying the physical and mechanical properties of frozen soil, especially changes in compressive strength under extremely low temperatures (dry ice: 0 to -80°C), is crucial to ensure the safety of engineering construction.

To date, the study of temperature, compressive strength, and stress-strain relationships in frozen soils has mainly focused on the range from 0°C to -30°C. However, research on the mechanical properties of frozen soil and the nature of unfrozen water under low-temperature conditions remains limited. There is no consensus on the relationship between temperature and compressive strength in frozen soils. Some researchers report that the uniaxial compressive strength of frozen soil increases linearly as temperature decreases. Others suggest that the relationship between compressive strength and temperature can be described by an exponential function. Due to the small temperature range, researchers have not reached a consensus on the relationship between temperature and soil compressive strength, and these studies have not met the engineering needs for soil stability under extremely low temperatures. Additionally, research on the relationship between unfrozen water content and compressive strength is scarce.

Based on the aforementioned review, comprehensive research on the compressive strength of frozen soil under extremely low temperatures is still insufficient. To fill this gap, this paper aims to:

(1) Determine the unfrozen water content in frozen soil at different temperatures using Nuclear Magnetic Resonance (NMR) technology;

(2) Establish an unfrozen water prediction model based on a GA-BP neural network under extremely low temperatures;

(3) Assess the damage, stress-strain relationships, changes in unfrozen water content, and compressive strength of frozen soil under extremely low temperatures;

(4) Provide valuable information for the application of ammonia salt refrigeration in artificial freezing projects.

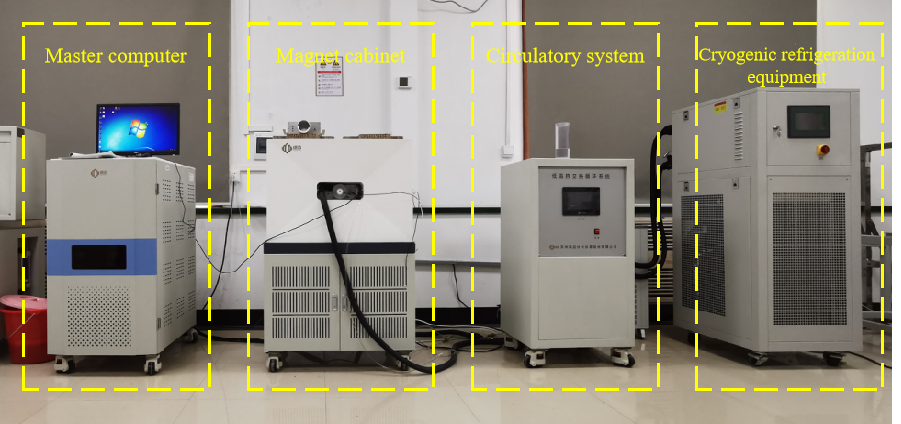

In the field of geotechnical engineering, the inherent advantages of Nuclear Magnetic Resonance (NMR) technology have gradually become apparent, making it an indispensable and commonly used tool in soil testing. Through NMR relaxation measurements, physical information such as porosity, pore size distribution, bound water, and permeability can be obtained. As shown in

Figure 1, the NMR imaging analyzer (model: MesoMR12-060H-I; manufacturer: Suzhou Niumag Analytical Instruments Co., Ltd.) is a high-precision low-field NMR analyzer that integrates relaxation spectrum analysis and imaging analysis. The analyzer’s magnet temperature is 32°C, the main magnetic field strength is 0.29 T, the magnet frequency is 12.319 MHz, and the frequency control accuracy is 0.1 Hz.

Figure 1 Niumag NMR Imaging Analyzer

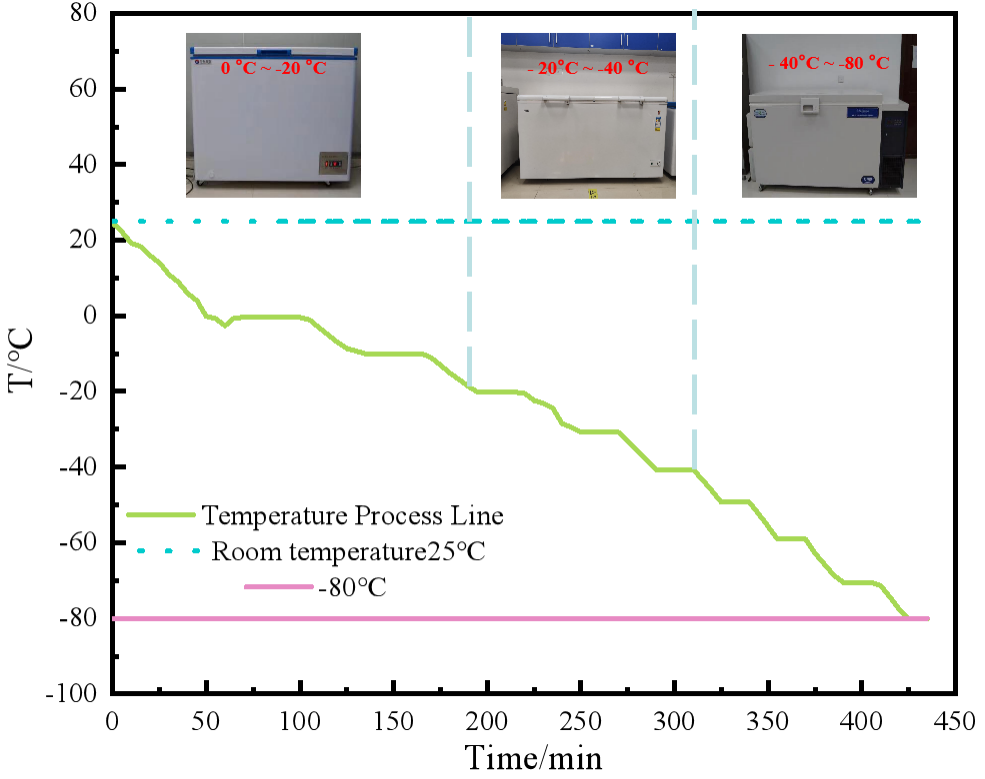

For the NMR tests, two sets of parallel samples were prepared. In this test, the sample temperature was monitored in real time, and a sample with identical initial conditions was chosen as a companion sample. A PT100 temperature sensor with a measuring range of -200~500°C and an accuracy of ±0.1°C was installed at the center of the soil sample placed in the low-temperature refrigeration equipment. To prevent the sample from cracking due to rapid freezing, different cooling strategies were applied to control the preparation of different samples. First, the sample temperature was lowered to -20°C using a conventional refrigerator. Then, the temperature was further lowered from -20°C to -40°C using a low-temperature refrigerator. Finally, the temperature was reduced from -40°C to -80°C using an ultra-low temperature freezer. The temperature changes of the sample were monitored using an XSL-D180LM2V0 inspection device. The test began when the overall temperature of the sample reached the target temperature. The cooling process is shown in Figure 2.

Figure 2 Cooling process

According to the cooling strategy, the samples were frozen, and the NMR signal intensity was measured in the range from 20°C to -80°C. Each NMR test involved the following parameters: 60 mm coil, CPMG (Carr-Purcell-Meiboom-Gill) RF sequence, 250 kHz sampling frequency, 15-fold simulated gain, 3000 echoes, 0.15 ms echo time, and 1000 ms wait time.

…

Phone: 400-060-3233

After-sales: 400-060-3233

Back to Top