Currently, shrinkage reducers are commonly used to address issues such as early shrinkage-induced loosening of the grout-rock interface and incomplete filling in grouting materials. However, the shrinkage mechanism of these additives remains controversial. This study investigates cement-based grouting materials with varying shrinkage reducer dosages, using low-field nuclear magnetic resonance (LF-NMR) technology to examine the T2 spectra during hydration. The study analyzes the effects of shrinkage reducer content on water migration and pore characteristics within cement-based grouting materials. Simultaneously, mechanical properties and drying shrinkage tests at different hydration ages were conducted to evaluate the impact of shrinkage reducers on flexural strength, compressive strength, and shrinkage rate. The experimental results show that during hydration, the content of bound water and pore water, as well as the most probable pore diameter of the cement-based grouting materials, increase with the addition of shrinkage reducers. However, as the hydration age increases, the extent of their influence gradually decreases. The main reason for the reduced shrinkage deformation is that shrinkage reducers reduce the evaporation of free water in the cement slurry, maintaining higher humidity during hydration, thereby lowering shrinkage stress.

With the rapid development of domestic rail transit projects, subway and other transportation infrastructure inevitably pass through complex geological environments, such as fault zones and karst formations. To ensure the safety of these projects, grouting filling technology has been widely applied in the treatment of such complex geological conditions. As a key factor influencing the effectiveness of grouting, the performance of grouting materials directly affects the safety and quality of engineering. Cement-based materials are widely used in rock grouting projects due to their low cost. However, cement-based grouting materials suffer from significant early shrinkage due to hydration reactions and changes in environmental humidity, leading to cracks between the grout body and the rock mass, which negatively impacts the grouting effect. To address this issue, adding shrinkage reducers has become an economical and effective solution. The shrinkage mechanism of these additives is currently debated, with theories including capillary tension theory, alkali ion concentration theory, and changes in pore solution pH theory.

Nuclear magnetic resonance (NMR) technology, as an innovative non-destructive testing method for cement-based grouting materials, can characterize the hydration process, pore structure, water migration, and diffusion characteristics of cement-based materials by analyzing the different states of water present in the materials.

This study uses ordinary Portland cement mixed with fly ash and desulfurization steel slag powder to form a composite cementitious system, considering both the incorporation of water reducers and shrinkage reducers. Cement mortar specimens were prepared, and nuclear magnetic resonance technology was used to analyze the effects of varying shrinkage reducer dosages on water migration and pore characteristics during the hydration process, aiming to clarify the shrinkage mechanism of shrinkage reducers.

1. Raw Materials: Ordinary Portland cement (P.O 42.5) from Conch Cement, grade II fly ash, desulfurization steel slag powder, river sand with a fineness modulus of 2.7, water reducer, and polyether shrinkage reducer SBT®-SRA(I).

2. Mix Ratio: Fly ash at 18% and desulfurization steel slag powder at 2.5% replacing the amount of cement, with a water-to-cement ratio of 0.39, sand-to-cement ratio of 2, water reducer at 0.6% of the cementitious material, and shrinkage reducer dosages of 0%, 0.5%, 1.5%, 2.5%, 3.5%, and 4.5% of the cementitious material.

3. Testing Method: Flexural and compressive strength tests and drying shrinkage tests were performed according to the “Method for Testing Cement Mortar Strength” GB/T 17671-1999 and “Drying Shrinkage Test Method for Cement Mortar” JC/T 603-2004. The specimens were demolded 24 hours after water addition, and after 2 days of curing, length changes were tested.

4. Testing Equipment: A low-field NMR machine (model MesoMR 12-060H, as shown in Figure 1) from Suzhou Newmay Analytical Instruments Co., Ltd. was used for the T2 spectrum tests.

5. Testing Content: The effects of varying shrinkage reducer dosages on water migration, pore characteristics, mechanical properties, and drying shrinkage deformation in cement-based grouting materials were analyzed.

Figure 1. Low-field NMR Machine

1. Mechanical Properties

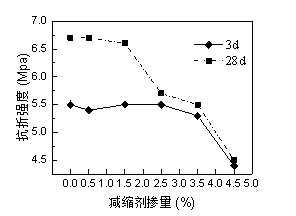

Figure 2 shows the effect of shrinkage reducer dosage on the 3-day and 28-day flexural and compressive strength of cement-based grouting materials. As shown in Figure 2(a), within the range of 0-4.5% shrinkage reducer dosage, the flexural strength of cement-based grouting materials decreases with increasing shrinkage reducer content after 3 days and 28 days. Especially beyond the critical dosage, the reduction in flexural strength becomes more significant. Similarly, the compressive strength of cement-based grouting materials follows a similar trend to flexural strength, with increased shrinkage reducer content leading to a decrease in compressive strength, as shown in Figure 2(b).

(a) Flexural Strength

(b) Compressive Strength

Figure 2. Effect of Shrinkage Reducer Dosage on Flexural and Compressive Strength

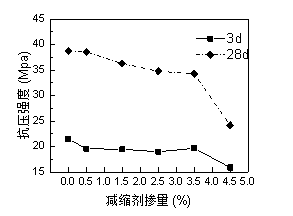

2. Drying Shrinkage

Figure 3 shows the effect of shrinkage reducer dosage on the drying shrinkage rate of cement mortar. It can be seen from the figure that the drying shrinkage rate decreases gradually with increasing shrinkage reducer dosage, but stabilizes as the age increases.

Figure 3. Effect of Shrinkage Reducer Dosage on Drying Shrinkage

3. Water Migration

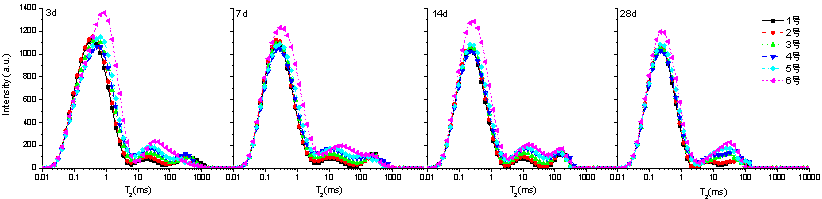

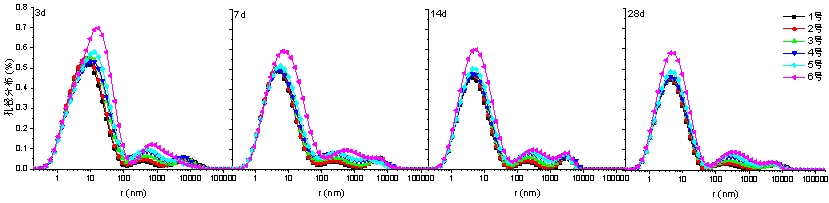

The authors used nuclear magnetic resonance technology to test cement mortar specimens at different hydration ages. The T2 relaxation results are shown in Figure 4, where the T2 spectrum shows three distinct peaks, corresponding to water in different phases. According to NMR principles, the peak position’s T2 represents the mobility of water molecules. A larger T2 value indicates higher mobility and weaker binding. The area under the peak represents the relative amount of that phase of water, with a larger area indicating more of that water phase; the ratio of the peak height shows the proportion of that phase in the total water content of the sample.

Figure 4. T2 Spectra at Different Hydration Ages

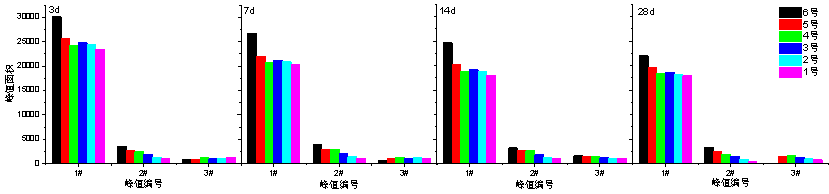

From the peak areas in Figure 4, the effect of different shrinkage reducer dosages on the content of water in different phases in cement-based grouting materials was analyzed, and the specific results are shown in Figure 5. From Figure 5, it can be seen that in cement-based grouting materials at different hydration ages, the content of adsorbed water is significantly higher than that of pore water and free water, with free water being the least. Additionally, the addition of shrinkage reducers affects the content of different phases of water, especially significantly impacting adsorbed water and pore water.

Figure 5. Peak Area at Different Hydration Ages

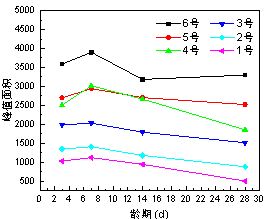

Further analysis of the changes in adsorbed water and pore water with hydration age is shown in Figure 6. From Figure 6(a), it can be seen that the adsorbed water content of cement-based grouting materials decreases gradually with increasing hydration age, with a larger reduction in the first 14 days, followed by stabilization. However, when the shrinkage reducer content is 4.5%, this stabilization is not observed in the later stages. Simultaneously, cement-based grouting materials with shrinkage reducers contain more adsorbed water than those without shrinkage reducers. From Figure 6(b), it can be observed that the addition of shrinkage reducers significantly increases the pore water content in cement-based grouting materials, and this increase becomes more pronounced with higher shrinkage reducer dosages. At the 7-day age, the pore water content increased compared to the 3-day age, but gradually decreased afterward. However, the decrease in pore water content is less pronounced in samples with shrinkage reducers, and when the shrinkage reducer content exceeds 3.5%, pore water content increases at the 14-day age.

(a) Adsorbed Water

(b) Pore Water

Figure 6. Adsorbed Water and Pore Water Content at Different Hydration Ages

4. Pore Structure Distribution

By transforming the T2 distribution into pore size distribution, the results are shown in Figure 7. The pore size distribution of cement-based grouting materials shows three peaks, corresponding to gel pores and capillary pores, capillary pores, and large pores. From Figure 7, it can be seen that the area of the first peak is significantly larger than the second and third peaks, and the pore size of the first main peak is considered to be in the most probable pore size range. At different hydration ages, most of the pores in cement-based grouting materials have pore sizes in the 1-100 nm range, and the pore size distribution varies significantly with different shrinkage reducer dosages, indicating that the micropore characteristics are related to the shrinkage reducer content. Additionally, the figure shows that the pores in cement-based grouting materials are primarily made up of micropores, and the addition of shrinkage reducers significantly increases the content of gel and capillary pores.

Figure 7. Pore Size Distribution of Cement-Based Grouting Materials

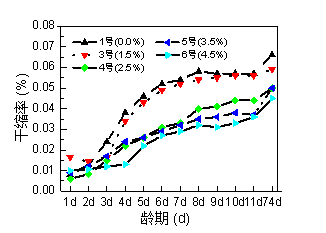

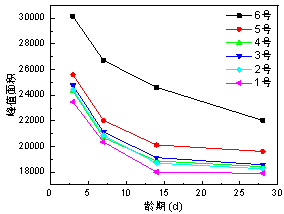

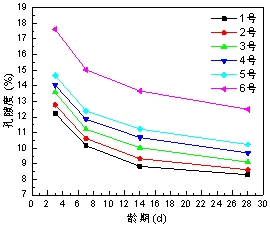

Figure 8 shows the effect of shrinkage reducer dosage over time on the porosity of cement-based grouting materials. The porosity of cement-based grouting materials decreases over time for different shrinkage reducer dosages, but with increasing shrinkage reducer content, the porosity increases. This suggests that porosity gradually increases with age, and after the 14-day age, the rate of porosity growth slows down. Moreover, the higher the shrinkage reducer dosage, the more significant the increase in porosity.

Figure 8. Porosity of Cement-Based Grouting Materials

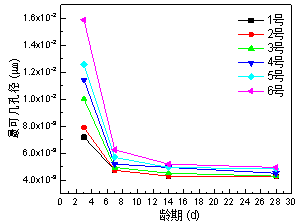

Figure 9 shows the most probable pore diameter at different hydration ages. It can be seen from the figure that as the shrinkage reducer content increases, the most probable pore diameter consistently increases. Compared with the blank group without shrinkage reducer, cement-based grouting materials with 2.5% and 4.5% shrinkage reducers showed increases of 39.09% and 120.52%, respectively, in most probable pore diameter at 3 days, and 4.99% and 14.97% at 28 days. Additionally, the influence of shrinkage reducer content on the most probable pore diameter decreases with increasing age.

Figure 9. Most Probable Pore Diameter of Cement-Based Grouting Materials

On one hand, the addition of shrinkage reducers increases the most probable pore diameter and porosity of cement-based grouting materials, as well as the number of capillary pores. This is the main reason for the reduction in flexural and compressive strength of the materials. On the other hand, shrinkage reducers also effectively increase the content of adsorbed water and pore water in the hydration products of the composite cement-based grouting material, maintaining a relatively high humidity during hydration. The increased gel and capillary pores help to reduce and counteract the surface tension and capillary tension caused by water loss, thus minimizing shrinkage deformation.

This study used LF-NMR technology to test the T2 relaxation times of cement-based grouting materials with added shrinkage reducers during hydration. The main conclusions are as follows:

(1) The addition of shrinkage reducers to cement-based grouting materials increases the content of adsorbed water and pore water, and this content increases with higher shrinkage reducer dosages.

(2) The incorporation of shrinkage reducers significantly increases the porosity and most probable pore diameter of cement-based grouting materials, with these values gradually increasing with higher shrinkage reducer content. At the same time, as the hydration age increases, porosity and most probable pore diameter decrease gradually.

(3) The shrinkage mechanism of shrinkage reducers is mainly due to their ability to increase the content of bound and pore water in cement-based grouting materials, reduce the evaporation of free water, and thus reduce the shrinkage stress and shrinkage deformation caused by changes in humidity.

If you are interested in the above applications, feel free to contact us at:18516712219

[1] Xiaodong W, Guangji Y, Lu X, et al. Spatiotemporal evolution of water and pore structure in cement-based material containing SRA by LF NMR[J]. Materials Today Communications, 2023.

Phone: 400-060-3233

After-sales: 400-060-3233

Back to Top