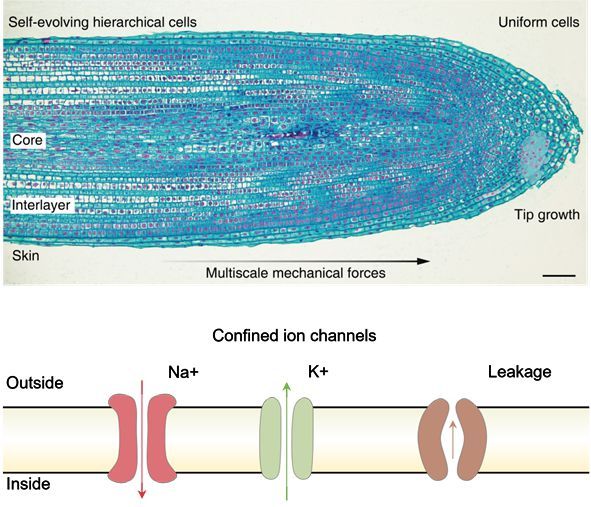

In biological organisms, interface fusion hierarchical structures are commonly found, such as tree rings, apple flesh and skin, and animal skin tissues. Although these structures have different densities, moduli, or components, their interfaces are fused together. These fused interface structures not only ensure efficient material exchange, energy transfer, and information interaction between multi-scale structures, but also balance the stress distribution between tissues to maintain equilibrium between overall and local mechanical properties. In addition to the initial encoding of hierarchical structures by genes, the forces and interactions generated by basic modules in situ also play a critical role in the evolution and formation of such interface fusion hierarchical structures. During the evolution of life, constrained transport channels for ultrafast selective ion or water transport spontaneously emerge within hierarchical structures. These constrained transport channels exhibit extreme sensitivity to the discreteness of ions or water and show unique transport characteristics. However, in the manufacturing process of artificial materials, achieving spontaneous fusion at interfaces and the in situ formation of constrained channels remains a significant challenge.

Figure 1. Cell tissue with interface fusion and constrained ion transport channels in biological organisms

Recently, Dr. Liu Yanjun from Professor Wu Peiyi’s team at Donghua University developed multi-material hydrogel fibers with interface fusion hierarchical structures. These fibers create hierarchical structures with different functionalities through in situ ion crosslinking-induced molecular shear flow. These fibers can achieve multi-modal behaviors similar to living organisms, such as spatiotemporal sensing, short-term memory, and adaptive deformation. In addition, these fibers also exhibit typical rhythmic characteristics, with an output voltage that changes periodically every 24 hours. As these hierarchical hydrogel fibers are made from natural building blocks and exhibit memristor-like effects similar to primary neurons, they hold promise for applications in seamless skin and implantable bioelectronics. Furthermore, this in situ stratification strategy can be easily applied to various one-dimensional or two-dimensional nanofillers to create high-performance nanocomposites with hierarchical structures. The related work, titled “Self-Evolving Hierarchical Hydrogel Fibers with Circadian Rhythms and Memory Functions,” was published in the journal Advanced Materials.

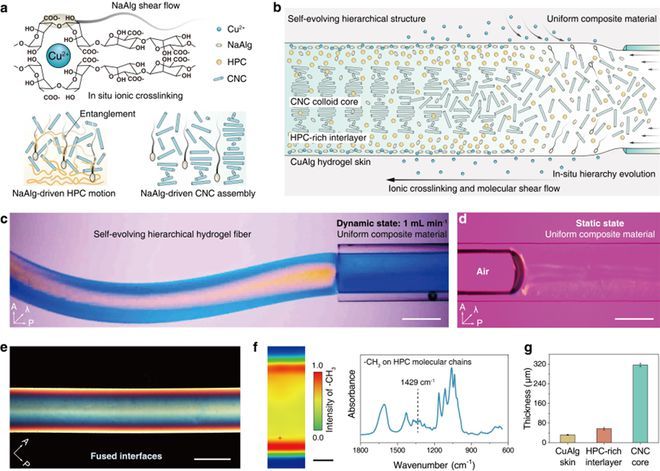

Researchers visually demonstrated the in situ stratification evolution process of the interface fusion hierarchical structure in multi-material hydrogel fibers using polarized optical microscopy. By using synchrotron radiation Fourier-transform infrared micro-spectroscopy (SR-FTIR), the distribution of methyl groups (1429 cm−1) in the hydrogel fibers was characterized, and the thickness of the stratified structure was precisely measured. The CNCs colloidal core layer serves as the functional layer, the hydroxypropyl cellulose (HPC)-rich intermediate layer serves as the mechanical strength layer, and the copper alginate (CuAlg) hydrogel skin layer serves as the protective layer.

Figure 2. The self-evolution process of hydrogel fibers and characterization of stratified structures

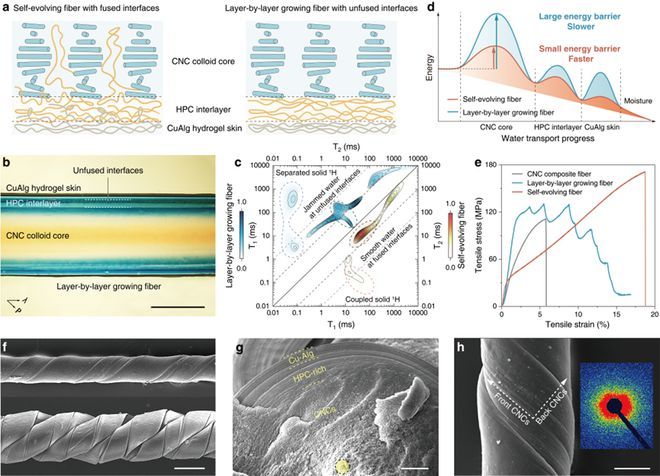

Researchers evaluated the differences in water transport between the two hierarchical structures of hydrogel fibers using two-dimensional low-field nuclear magnetic resonance (LF-NMR). The fusion of the interface created a continuous and integrated structure between the CNCs colloidal core layer, the HPC-enriched intermediate layer, and the CuAlg hydrogel layer. This integrated structure reduces the energy barrier during water transport between layers, allowing for smoother and faster water exchange between the fibers and the environment. The interface fusion also allows for uniform dispersion of mechanical forces between the different layers, maintaining a balance between the overall and local mechanical properties. This fused interface also offers advantages in the subsequent twisting processing of the fiber, ensuring structural integrity during the twisting process. During the twisting process, over-twisting of the fiber not only reduces defects in the CNCs core layer but also forces CNCs to align, thereby creating mesoscale constrained narrow slits. These extremely constrained narrow slits are highly sensitive to water discreteness, which makes the fiber exhibit unique water transport characteristics.

Figure 3. Characteristics of the interface fusion stratified structure and the water transport and force transmission processes dominated by this structure

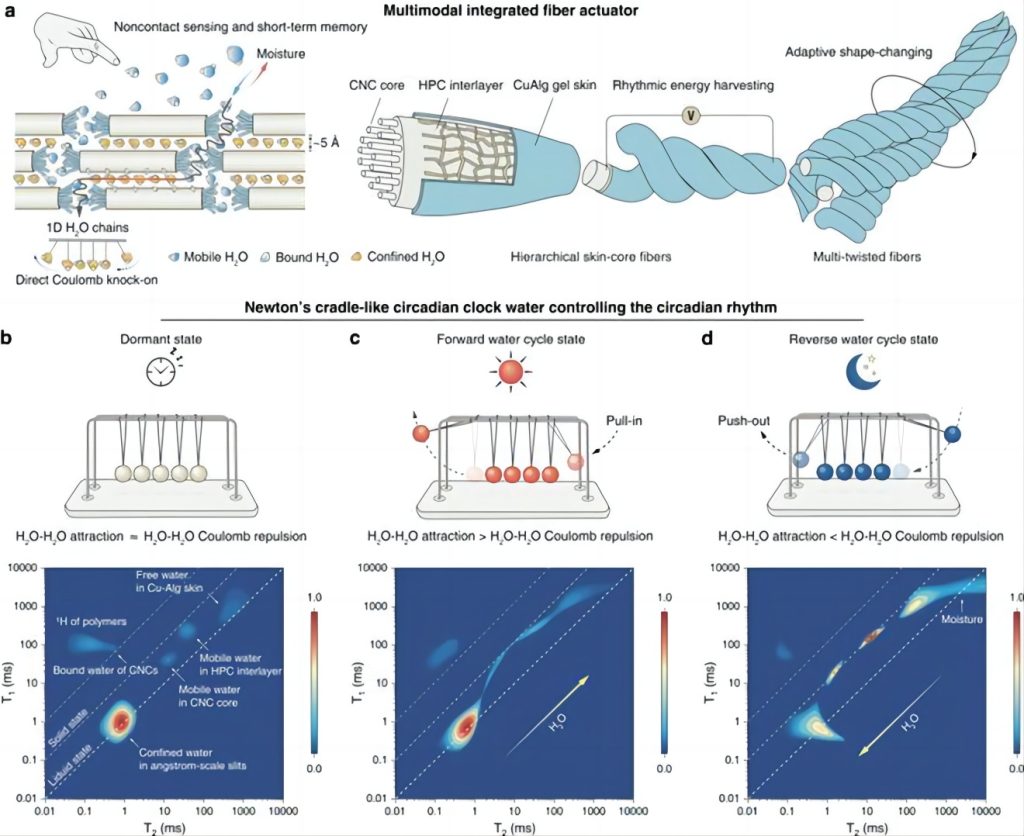

In the mesoscale constrained narrow slits formed by CNCs, water is transported through direct Coulombic collisions, similar to the motion of a Newton’s pendulum. Compared to disordered water diffusion, this collective motion mode shows higher sensitivity to changes in the water within the fiber. This Newton’s pendulum-like collective water motion, combined with interface fusion, enables efficient water transport across layers, forming a highly sensitive negative feedback loop within the fiber. The constrained water in the CNCs core layer has very low activity, but its mobility is T1/T2 = 1.02, which is close to the ideal value (T1/T2 = 1). This nearly ideal constrained water functions as a master clock that controls the circadian rhythm behavior of the twisted fiber. When the moisture content in the environment matches the constrained water, both cease exchanging, and the fiber enters a dormant state. When the environmental moisture content is lower than the constrained water, the fiber enters a forward cyclic state, and the constrained water starts to transfer to the surrounding environment. When the environmental moisture content exceeds the constrained water, the fiber enters a reverse water cycle state, and the water in the environment is transferred into the fiber. The spin distribution shape of the constrained water confirms these three different exchange modes.

Figure 4. Running mechanism of biological clock water in hydrogel fibers

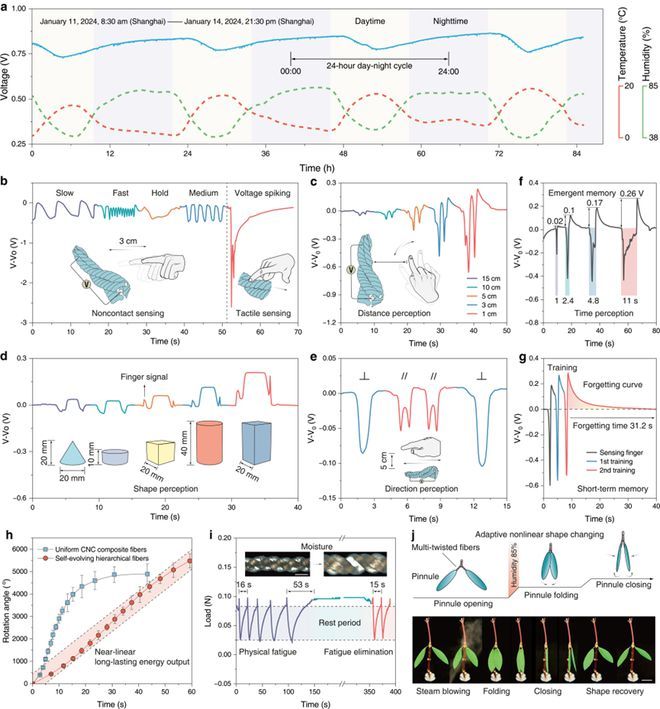

Multimodal Responsive Fibers: Circadian Rhythm, Sensing, Memory, and Adaptive Deformation Properties

Figure 5. Display of multimodal functions of the fibers: circadian rhythm, sensing, memory, and adaptive deformation

This work proposes a simple in situ stratification evolution strategy for manufacturing interface fusion hierarchical hydrogel fibers with built-in rhythmic clocks and memory. The fusion of interfaces creates an integrated structure between the CNCs colloidal core layer, the HPC-enriched intermediate layer, and the CuAlg hydrogel layer. This integrated structure reduces the energy barrier for water transport between layers, making water exchange between the fibers and the environment smoother and faster. These fibers exhibit typical circadian rhythms, non-contact spatiotemporal sensing, short-term memory, and adaptive deformation, among other biomimetic characteristics. Furthermore, these self-evolving stratified hydrogel fibers are made from fully natural building blocks, presenting a sustainable and environmentally friendly material manufacturing approach. This in situ stratification evolution strategy can also be easily applied to various one-dimensional or two-dimensional nanofillers to produce high-performance nanocomposites with hierarchical structures.

This article is reprinted from: Frontiers in Polymer Science. Please contact us for removal if there is any infringement.

Phone: 400-060-3233

After-sales: 400-060-3233

Back to Top