Frequent mining disturbances or periodic rupture of the distant roof during coal seam extraction generate multiple vibration loads, which significantly impact the micro-porosity structure and macroscopic mechanical behavior of coal samples. To explore the evolution of coal sample pore structure under vibration loads, a bituminous coal sample was selected, and multiple vibration load impact tests were conducted using the Hopkinson pressure bar (SHPB) testing system. The T2 spectra of the coal samples after each impact were tested using a low-field nuclear magnetic resonance (NMR) analyzer, and the distribution of pore fractures and their damage evolution characteristics were analyzed through magnetic resonance imaging (MRI).

Coal is the main energy source in China. As the depth of coal mining increases, the mining conditions become more complex. During coal seam extraction, disturbances such as mine earthquakes, blasting, and excavation activities frequently apply vibration loads to the coal body, continuously damaging its pore structure and creating cumulative damage effects that can lead to large-scale dynamic failure, resulting in coal and rock dynamic disasters that pose significant risks to mining safety.

Researchers have conducted extensive studies on coal damage and failure under impact loads using laboratory tests, especially with the SHPB testing system, which has been widely used in coal dynamics research. These studies mainly focus on macroscopic failure, particularly surface damage, without addressing the damage and failure characteristics of the coal’s pore structure. Some researchers have incorporated techniques such as 3D contour scanning, scanning electron microscopy (SEM), and CT scanning to study the damage characteristics of the coal’s microstructure under impact loads. Nuclear magnetic resonance (NMR) is a high-precision, non-destructive technique for testing pore structures and can be used to analyze the evolution characteristics of the pore fracture structure in coal and rock bodies.

This study focuses on the evolution characteristics of coal pore structures under multiple vibration load impacts. Using the SHPB testing system, vibration load impact tests were conducted on coal samples. The T2 spectra, porosity, and MRI images of the coal samples after each impact were analyzed to study the distribution of pores and fractures, as well as the evolution of signals in MRI imaging. The evolution characteristics of the coal pore structure and the damage evolution mechanisms were identified. The study revealed the coal and rock body failure mechanisms under frequent vibration load impacts. These findings contribute to a deeper understanding of the dynamic disaster mechanisms induced by dynamic loads in mining sites and provide theoretical support for preventing and controlling deep composite dynamic disasters.

According to the standards recommended by the International Society for Rock Mechanics and Rock Engineering (ISRM), the coal samples were cut, cored, and polished to obtain standard coal samples measuring 50mm × 50mm. The end face flatness was less than 0.02mm, the maximum deviation did not exceed 0.25°, and both ends were perpendicular to the coal sample axis, as shown in Figure 1.

Figure 1 Coal Sample

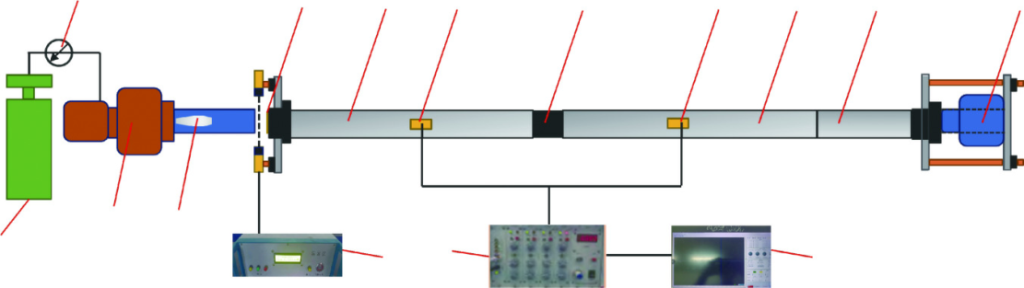

The vibration load impact test was conducted using the SHPB system, which includes the following components: axial loading device, pressure bar device, impact bullet drive device, dynamic strain gauge, and laser velocimeter, as shown in Figure 2.

Figure 2 SHPB Pressure Bar Test System Structure

Before the test, a trial impact was conducted to determine the impact air pressure at 0.30 MPa. Strain gauges were attached to the incident and transmission rods to capture the pulse signals generated by the vibration impact. Dynamic strain gauges were used to collect and record the signals, which were used to assess the performance of the test system.

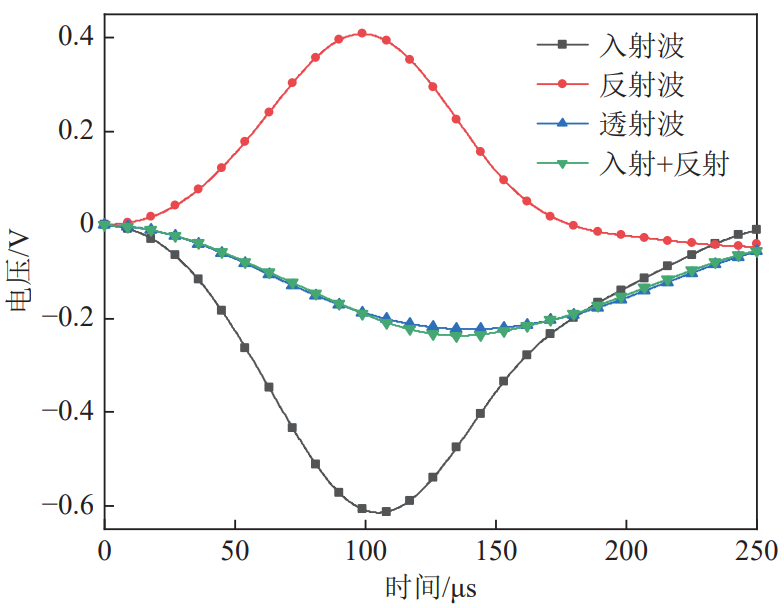

After the coal body was impacted by vibration loads, the sum of the incident and reflected wave stresses was approximately equal to the transmitted wave stress, indicating that the stress balance condition was met. This confirms that the coal sample adhered to the assumption of stress uniformity during the vibration load impact process, as shown in Figure 3.

Figure 3 Dynamic Stress Balance Curve of Coal Sample

When the cumulative energy input exceeds the critical failure value of the coal sample, macroscopic cracks appear, causing progressive damage and failure of the coal sample. The test was stopped when macroscopic cracks were observed on the coal sample’s surface.

The coal samples subjected to vibration load and water saturation treatment were tested using nuclear magnetic resonance to obtain the T2 spectra and perform MRI imaging. The tests were conducted with the medium-sized NMR core analysis system (Manufacturer: Suzhou Newmai Analytical Instrument Co., Ltd., Model: MecroMR12-150H-VTHP), as shown in Figure 4.

Figure 4 NMR Analyzer

Analysis of Evolution Characteristics of Coal Pore Fracture Structure

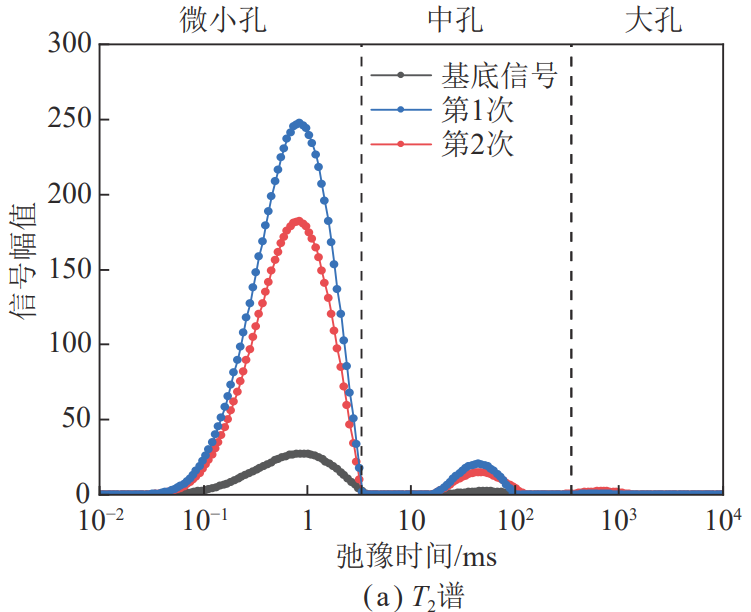

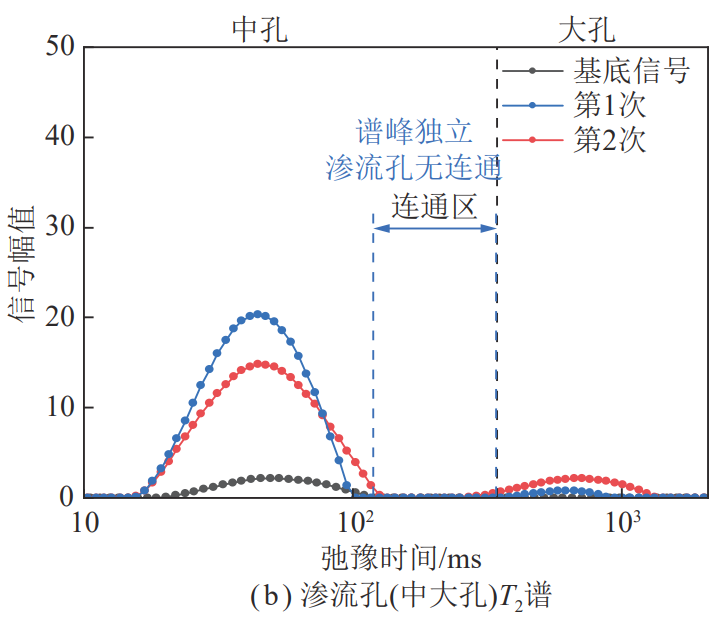

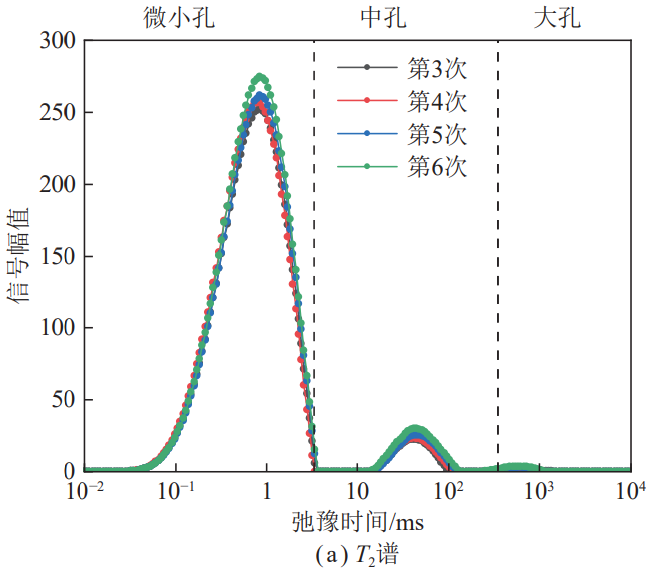

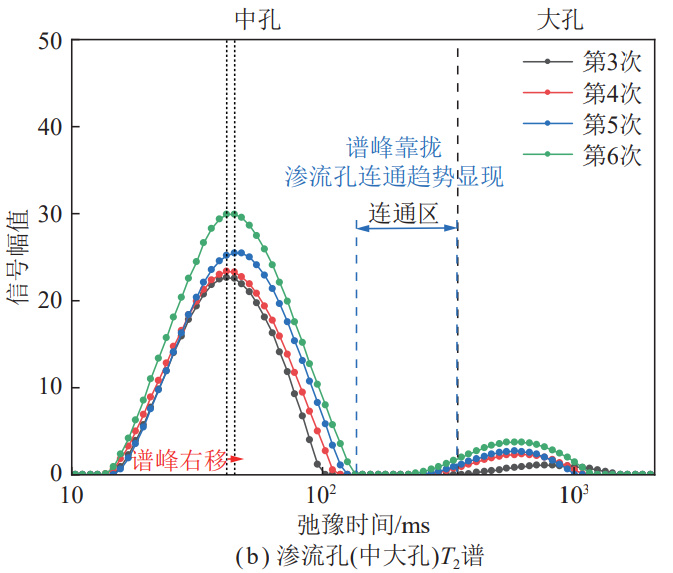

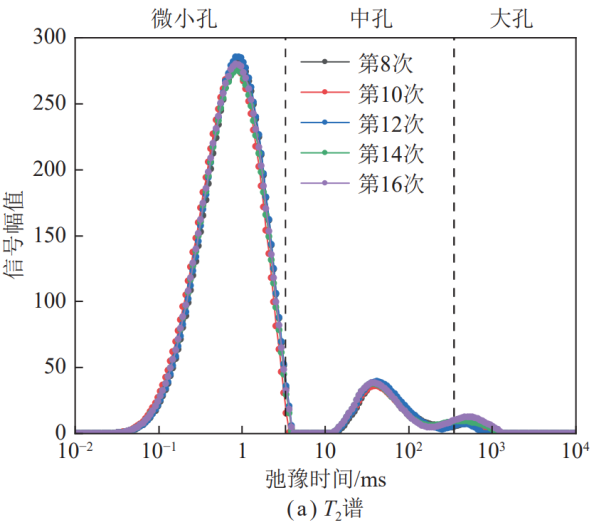

Through nuclear magnetic resonance testing of the coal samples subjected to vibration loads, the evolution characteristics of the pore fractures were analyzed. According to the T2 spectrum pore classification method, coal sample pores are divided into micropores (T2<3.33ms), mesopores (3.33ms≤T2<344ms), and macropores (344ms≤T2). Micropores are also called adsorption pores, while meso and macropores are collectively referred to as seepage pores. Based on the positions of the peaks in the T2 spectra, the evolution process of the coal pore structure under multiple vibration load impacts can be divided into four stages.

(1) Stage of Rapid Increase in Adsorption Pores: The T2 spectrum shows a clear bimodal shape. The internal connectivity of the coal sample is poor, and the peaks are independent of each other. The area of the adsorption pore spectrum increases significantly. After the initial vibration load impact, the area of the adsorption pore spectrum increased approximately fivefold compared to the initial state, primarily reflecting damage to the coal matrix and the formation of numerous new adsorption pores.

Figure 5 Evolution Curve of Adsorption Pore Spectrum in Coal Samples

(2) Pore Stabilization Growth Stage: In this stage, the T2 spectrum shows a tri-peak distribution. The peaks are still relatively independent, and the internal connectivity of the coal sample remains poor. Microcracks have not yet appeared. After multiple impacts from vibration loads, seepage pores develop, the peaks shift right, relaxation times increase, and the peaks between mesopores and macropores begin to “merge.” The connectivity of the seepage pores starts to become apparent.

Figure 6 Evolution Curve of the T2 Spectrum in the Pore Stabilization Growth Stage

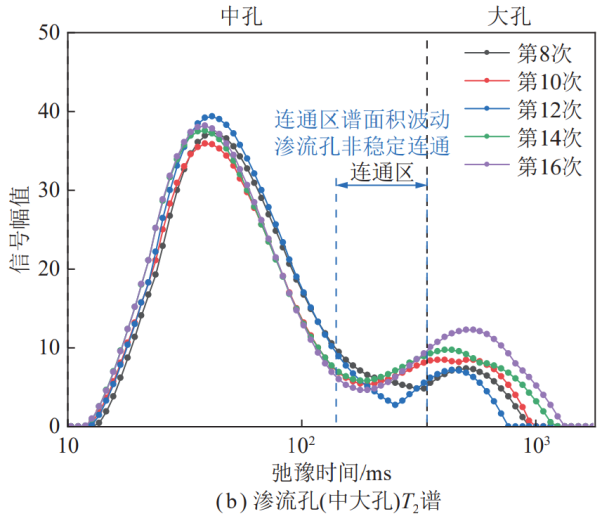

(3) Microcrack Formation Stage: In this stage, mesopores develop into macropores and microcracks, leading to the distribution of pores in the 138–344 ms range. The connectivity of the coal sample improves, and a “merging” phenomenon appears in the peaks between mesopores and macropores. Microcracks start to form but are still heavily influenced by vibration waves.

Figure 7 Evolution Curve of the T2 Spectrum in the Crack Formation Stage

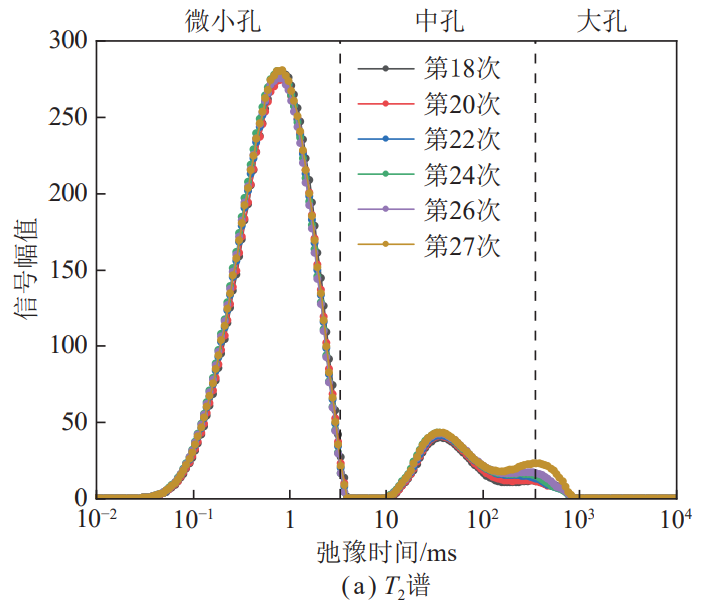

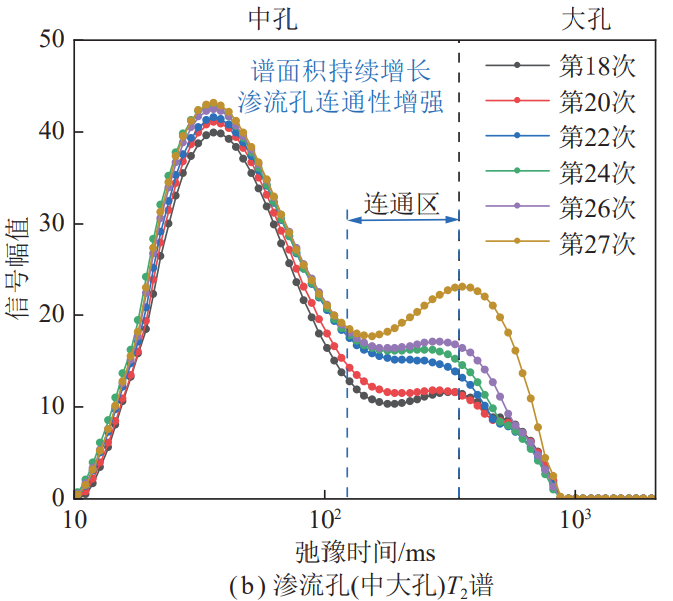

(4) Crack Connectivity Stage: On one hand, mesopores in the seepage pores continue to evolve into macropores and gradually form new cracks. On the other hand, various pore fracture structures formed in the coal sample under previous vibration load impacts continue to develop and connect. The volume of seepage pores rapidly increases, and the connectivity of seepage pores significantly enhances, until macroscopic cracks appear on the coal sample’s surface, leading to a drop in peak stress.

Figure 8 Evolution Curve of the T2 Spectrum in the Crack Connectivity Stage

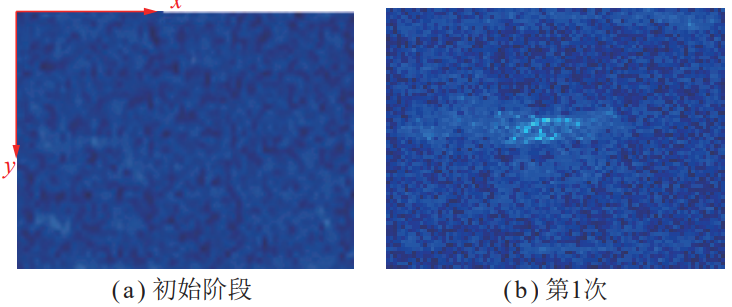

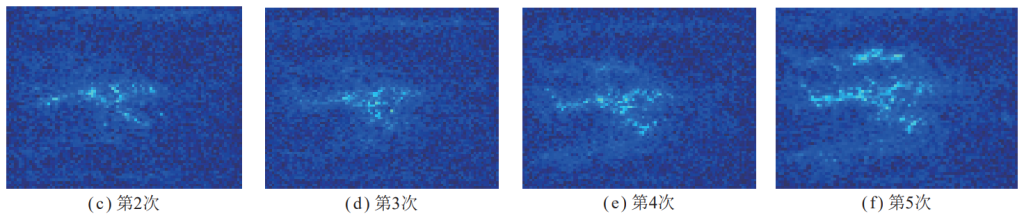

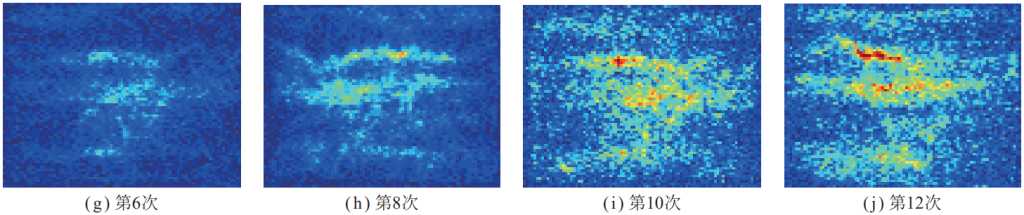

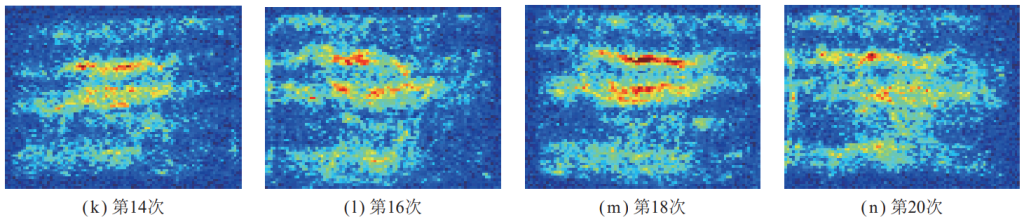

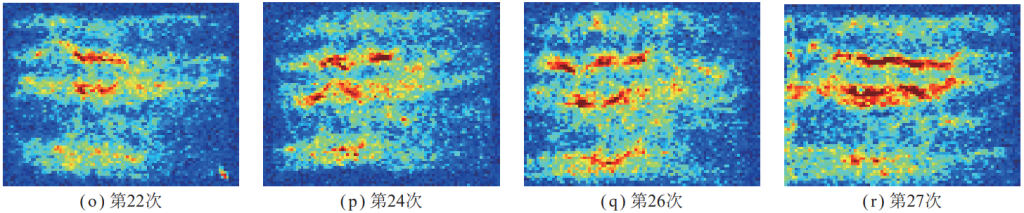

The nuclear magnetic resonance (NMR) device was used to analyze the spatial water distribution inside the entire coal sample, and the 2D projection was used to reverse the MRI images of the coal sample. Since seepage pores accumulate more water, the areas with significantly enhanced signals in the MRI images correspond to the regions where the seepage pore volume has increased considerably. The growth of seepage pore volume can partially reflect the changes in the coal sample’s damage. Therefore, MRI images can be used to analyze the damaged areas within the coal sample.

By comparing the changes in the 2D MRI images of the coal sample after multiple vibration load impacts, the distribution and developmental characteristics of the damage regions within the coal sample can be intuitively observed.

Figure 9 MRI Images of Coal Samples After Vibration Load Impact

Phase I: Due to the relatively dense nature of the coal sample and its low porosity, the signal response in each region of the sample is very weak at the initial stage, as shown in Figure 9(a)–(c). The vibration wave produced by the impact is transmitted from the high impedance bars to the low impedance coal sample, with the waveform undergoing multiple deflections. During this process, the coal matrix undergoes damage, forming new adsorption pores. A few damage regions are created within the coal sample, appearing as dot-dispersed distributions.

Phase II: As the number of vibration load impacts increases, seepage pores begin to gradually increase. The signal response of the damage regions strengthens, and a trend toward a shift from dot-dispersed distribution to strip-concentrated distribution appears, as shown in Figure 9(d)–(g).

Phase III: The response signals within the damage regions start transitioning from dot-dispersed distribution to strip-concentrated distribution, as shown in Figure 9(h)–(l). On one hand, the energy carried by the vibration waves is used to expand mesopores, and some mesopores merge with other pore structures to form cracks. On the other hand, the reflection and stretching of the stress waves during propagation cause macropores and fractures to rupture. Energy is not fully used to develop the already-formed fractures, leading to unstable growth in the connectivity of the fractures within the coal sample, until the 18th vibration load impact. The cracks start to interweave, and the MRI image shows distinct strip-shaped damage areas.

Phase IV: The strip-shaped damage regions show complex strip patterns, as shown in Figure 13(m)–(r). The vibration load impacts continuously connect the fractures. The color in the original signal accumulation regions becomes deeper, and the areas expand. The multiple vibration load impacts continuously extend and connect various pores and fractures inside the coal sample. Eventually, macroscopic cracks appear on the surface of the coal sample.

1. The SHPB test system was used to conduct experimental research on the evolution characteristics of pore fracture structures in bituminous coal under multiple vibration load impacts. The T2 spectra and changes in pore distribution were analyzed using a low-field NMR system, studying the damage evolution of the coal sample’s pore structure under multiple vibration load impacts.

2. Under multiple vibration load impacts, as the number of vibration load applications increases, both the peak stress and dynamic elastic modulus of the coal sample show a linear decrease, indicating that the impact of vibration loads significantly weakens the coal sample’s ability to bear loads and resist deformation.

3. Under multiple vibration load impacts, from initial loading to the appearance of macroscopic fractures, the porosity of the coal sample increased by six times compared to the original coal sample. The pore structure evolution process of the coal sample can be divided into four stages: adsorption pore rapid increase, pore stabilization growth, microcrack formation, and crack connectivity.

4. Combining MRI imaging and pore fractal dimension results, multiple vibration load impacts caused the damage regions of the coal sample to transition from dot-dispersed distribution to a complex strip interwoven pattern. The fractal dimension of the pores decreased, the connectivity of the pore network increased, and the damage degree worsened.

Medium-Sized NMR Imaging Analysis System

[1] Ma Y, Huang Q, Kong X, et al. Experimental study on the evolution characteristics

Phone: 400-060-3233

After-sales: 400-060-3233

Back to Top