Loess is widely distributed in seasonally frozen and permafrost regions of northern and western China. With the growing demand to enhance connectivity between inland areas and eastern coastal cities, an increasing number of transportation infrastructure projects—such as the Qinghai-Tibet Railway and the Urumqi-Lhasa High-Speed Railway—have emerged. In these areas, due to the scarcity of coarse-grained materials, locally sourced loess is often used as subgrade fill. However, the natural dynamic properties of loess generally fail to meet the rigorous demands of these major projects. Furthermore, the persistent freeze–thaw (F-T) cycles caused by drastic temperature fluctuations induce volumetric expansion, disruption of particle bonding, and structural breakdown, severely compromising infrastructure durability and long-term serviceability.

Conventional stabilisers such as lime and cement are becoming increasingly expensive and are also significant contributors to global carbon emissions. Therefore, it is crucial to adopt environmentally friendly alternatives. Among low-carbon stabilising materials, nano-magnesium oxide (NM) has emerged as a promising candidate due to its strong binding properties and high stability. Over the past few decades, considerable research has focused on how NM improves the static performance of soils. Studies show NM enhances particle cohesion, fills pore spaces, and significantly improves strength and compressibility. However, its effects on dynamic behaviour—particularly under F-T conditions—remain inadequately explored.

This study evaluates the enhancement of dynamic properties and freeze–thaw resistance of loess using NM. Samples with varying NM contents were prepared and subjected to a series of dynamic triaxial tests. Results revealed that adding 2.5% NM increased the maximum shear modulus of the unfrozen and post-thaw samples by an average of 75.26% and 184.9%, respectively. It was also observed that F-T-induced structural deterioration is closely tied to moisture content and water phase. Notably, these adverse effects can be mitigated by NM. A new NM-based soil improvement approach is proposed for cold-region infrastructure. NMR testing revealed that NM promotes water absorption, converting free water into bound water, thereby improving dynamic behaviour and frost durability. The findings confirm that NM is a highly functional additive for stabilising loess in F-T environments.

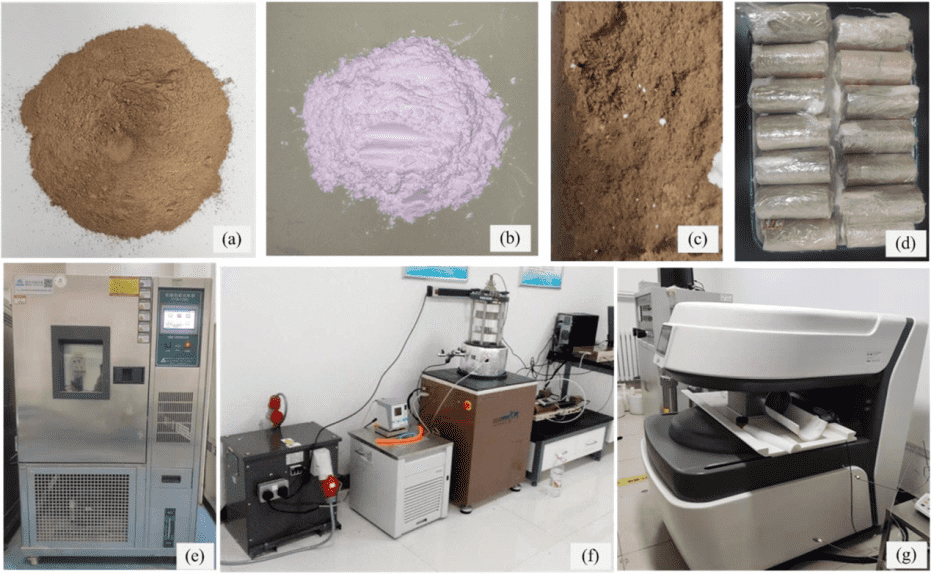

Sample preparation, dynamic triaxial testing, and NMR analysis were conducted at a key laboratory in Xi’an, China. Dried loess was ground and passed through a 2 mm sieve, then baked with NM at 110°C for 24 hours. Based on predetermined mix ratios, the materials were manually mixed and compacted into cylindrical specimens. The dry density for all samples was controlled at 1.60 g/cm3. Specimens were sealed and cured at 20±2°C for 28 days.

After curing, freeze–thaw cycles were conducted in a programmable temperature chamber, alternating between -10°C and 20°C.

Figure 1: (a) Loess; (b) Nano-MgO; (c) NM-treated Loess; (d) Sample Specimens; (e) F-T Chamber; (f) Dynamic Triaxial Setup; (g) NMR Analyzer

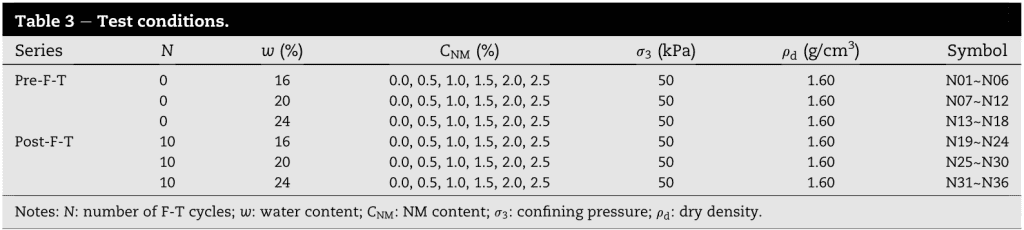

Table 1: Experimental Parameters of Samples

Dynamic Triaxial Testing:

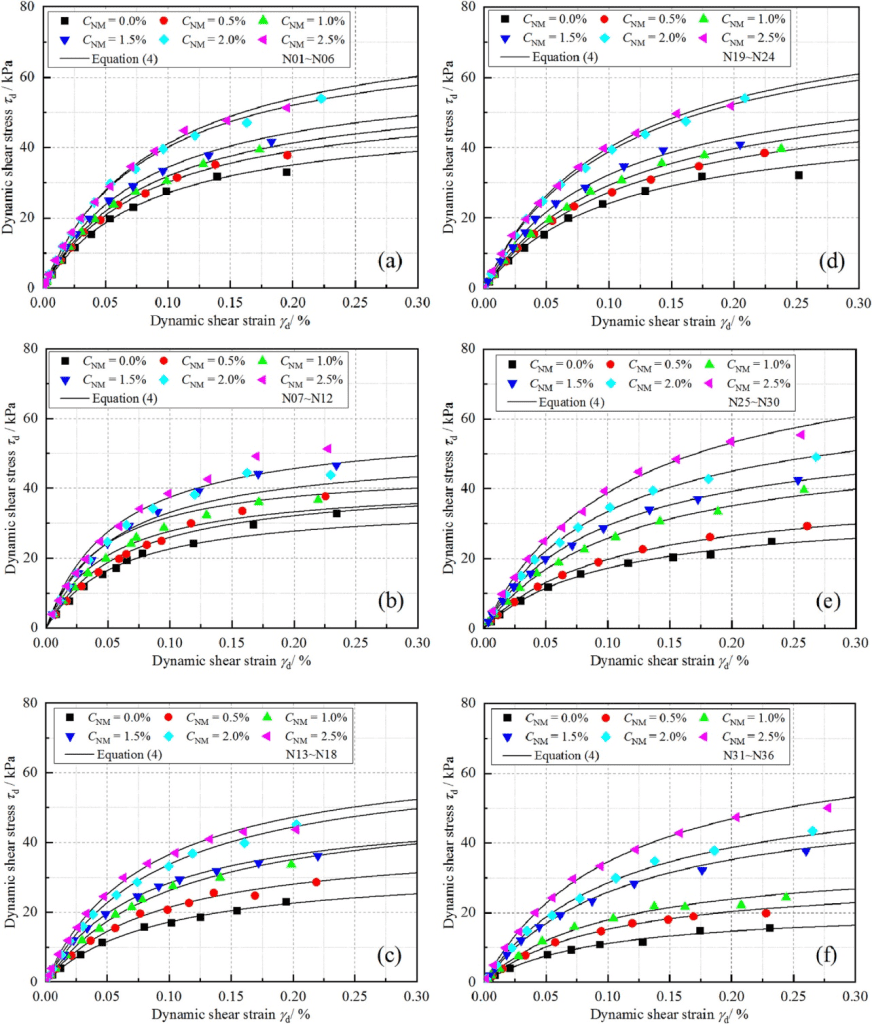

Figure 2: Dynamic Shear Strain–Stress Response of Samples

Figure 2 shows the dynamic shear strain–stress curves for samples with 0% to 2.5% NM, before and after F-T cycles. All samples exhibited strain-hardening behaviour and conformed to the Hardin model. Notably, the curves shifted upward with increasing NM content, indicating higher shear stress at equivalent strain levels.

Table 2: Variation of Shear Strength Parameters

Taking the pre-F-T samples as an example (Table 2), as moisture increased from 16% to 24%, the shear stress decreased by 33.56%, 26.25%, 9.22%, 18.09%, 11.92%, and 15.02% for NM contents of 0%, 0.5%, 1.0%, 1.5%, 2.0%, and 2.5%, respectively. This confirms that NM significantly mitigates the negative effects of water on shear strength.

Figure 3: Dynamic Shear Strain–Modulus Relationship of Samples

Figure 3 presents the relationship between shear strain and dynamic modulus under varying test conditions. As expected, shear modulus generally decreased with increasing strain—initially at a slow rate, followed by a sharp drop. The curves shifted upward with higher NM content and downward with increased moisture, highlighting the damaging effect of water and the effectiveness of NM in enhancing F-T resistance in loess.

Low-Field NMR Testing:

Tests were conducted using the Suzhou Niumag low-field NMR instrument, model: MacroMR12-150H.

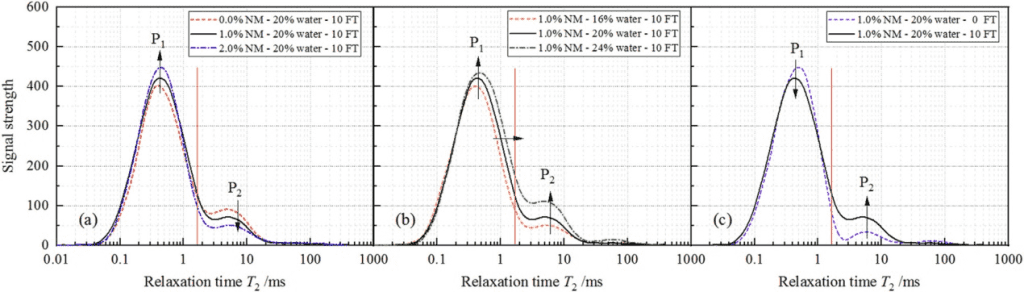

Figure 4: NMR T2 Relaxation Spectrum of NM-Treated Loess

Figure 4 displays T2 relaxation time distributions of NM-treated loess under different test conditions. Signal intensity reflects water content in the sample, while T2 inversely correlates with surface tension, providing insight into water state. A red vertical line at 1.65 ms indicates the threshold between bound and free water—signals to the left represent bound water; to the right, free water.

As shown in Figure 4a, the T2 spectra exhibit bimodal distributions (P1 and P2). Both peaks lie between 0.05 and 3 ms, with the dominant peak on the bound water side. With increasing NM content, P1 peak intensity rises while P2 decreases, suggesting that NM converts free water into bound water. This shift is attributed to the surface effects of nanoparticles, which promote water binding during hydration, improving dynamic performance and frost resistance.

In Figure 4b, increasing moisture content shifts the T2 curve toward longer relaxation times and higher intensity, indicating increases in both bound and free water. Under F-T cycling (Figure 4c), P1 and P2 peaks shift slightly rightward, with P1 intensity declining and P2 rising—implying a reduction in bound water and increase in free water, likely due to moisture redistribution during freeze-induced migration.

1. F-T cycles degrade the shear resistance of loess. Elevated moisture content also has a significant detrimental impact. However, these negative effects can be effectively mitigated with NM. At 2.5% NM content, the maximum shear modulus increased by 75.26% (pre-F-T) and 184.9% (post-F-T), respectively.

2. NMR analysis supports the mechanism behind NM’s stabilisation effect under F-T conditions. NM promotes water absorption, transforming free water into bound water. This fundamentally enhances dynamic behaviour and reduces F-T damage in loess samples.

Recommended Equipment for F-T Testing, Pore Distribution, and Unfrozen Water Measurement:

Shufeng Chen, Xikang Hou, Tao Luo, et al. Effects of MgO Nanoparticles on Dynamic Shear Modulus of Loess Subjected to Freeze-thaw Cycles[J]. Journal of Materials Research and Technology, 2022. 18:5019–5031.

Phone: 400-060-3233

After-sales: 400-060-3233

Back to Top