In the food industry, the formation of fat crystal networks occurs in two stages. The first stage involves rapid crystallisation during processing via cooling and kneading, producing fine and stable crystals, which then undergo a maturation process to form structurally stable crystallised products. The second stage occurs during storage and transportation, where the behaviour of these matured crystallised fats may change until they reach the end consumer.

The dynamic process of fat crystallisation can generally be described as follows: supercooling drives triglyceride molecules to arrange in ordered molecular layers; these layers stack to form nanoscale microcrystals; individual microcrystals aggregate and grow into crystal clusters; finally, clusters further aggregate, intertwine, and fill spaces to form a three-dimensional crystalline network, which is the macroscopically visible solid fat. The 3D network structure of fat crystals is analogous to flocculated colloidal structures. Variations in crystallisation conditions significantly influence the network formation and macroscopic properties, ultimately determining the product quality.

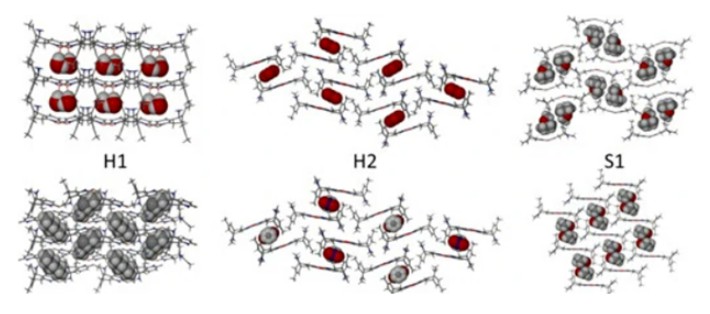

Polymorphism refers to the occurrence of more than one crystalline form in a single substance. Triglycerides, composed of one glycerol molecule and three fatty acids, form crystals where methylene groups in the fatty acid chains adopt zigzag arrangements. The entire triglyceride molecule typically aligns as dimers or trimers. Variations in triglyceride arrangement and fatty acid embedding lead to differences in subcellular structures, producing distinct crystal forms, known as polymorphism.

Research shows that fats primarily exhibit three polymorphic forms: α, β′, and β. For the same triglyceride, melting points, stability, and enthalpy increase sequentially from α → β′ → β. Rapid cooling of molten fats typically produces α crystals, which appear briefly at the initial processing stage and gradually transform into β′ and β crystals. Slow heating of solid fat above its melting point often produces β′ crystals, which are fine, plastic, spreadable, and offer excellent mouthfeel—ideal for shortenings, margarine, and spreads. Slow melting and controlled crystallisation above the melting point, or low-temperature recrystallisation from solvent, yields β crystals, which are coarser. Polymorphic transitions can occur among crystal forms, generally following the sequence α → β′ → β, influenced by temperature, time, and processing conditions during production and storage.

Fat polymorphism impacts crystallisation behaviour—including rate, crystal size, morphology, and total crystal content—which directly affects product physical properties. Studying fat crystallisation has both scientific and practical significance. Analysing crystallisation behaviour guides production processes to achieve desired texture and mouthfeel. Each lipid exhibits unique crystallisation behaviour, influencing the 3D arrangement within the fat crystal network. Factors such as cooling rate, fatty acid chain length and composition, TAG organisation, and processing parameters (e.g., stirring speed) greatly affect crystal structure. Variations in cooling rate can also modify microstructure by controlling nucleation and growth rates.

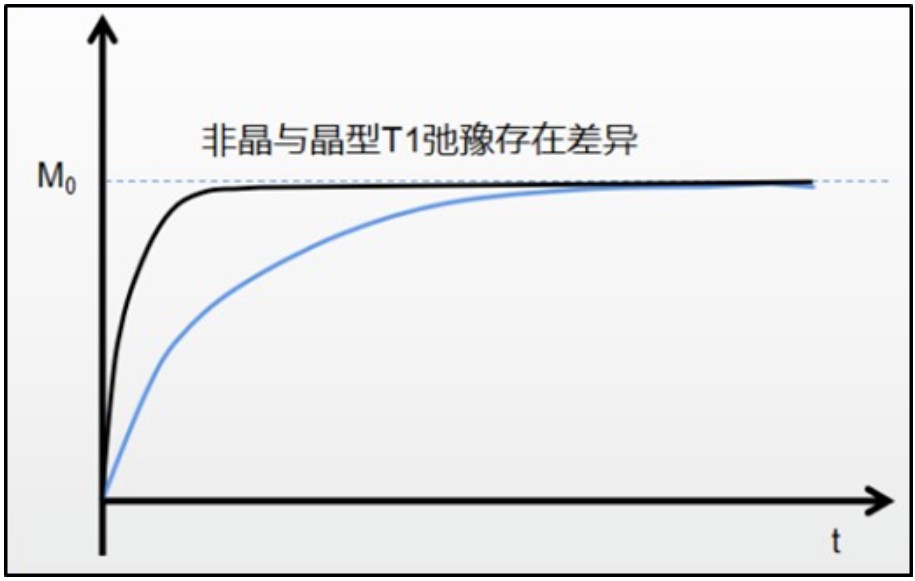

Time-domain NMR (TD-NMR) relaxation measurement is a rapid, non-destructive method to evaluate physical and chemical changes in food systems. TD-NMR typically measures relaxation times using different pulse sequences, including longitudinal (T1) and transverse (T2) relaxation times, which correlate with physicochemical changes in foods. While restricted molecular mobility in solid fats limits TD-NMR for detecting polymorphism, combining relaxation time measurements with complementary methods still allows study of polymorphism and crystal size distribution.

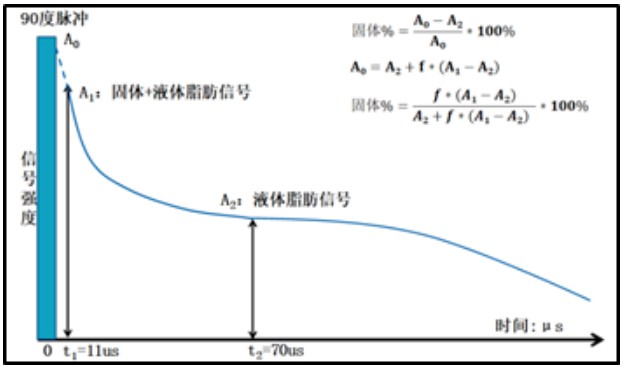

Measurements of solid fat content (SFC), T1 (spin-lattice relaxation), T2 (spin-spin relaxation), and second moment (M2) provide insights into fat crystallisation and molecular mobility. TD-NMR can quickly offer valuable information on molecular changes within the entire sample volume due to crystallisation without detailed spectral analysis. Compared to XRD, TD-NMR gives additional insights into molecular dynamics and conformational freedom, supplementing XRD data, especially in liquid states, and aiding assessment of overall crystallisation behaviour. Interpretation of TD-NMR parameters, however, should be cross-validated with reliable methods like XRD.

The number of fat crystals affects the macroscopic properties of the crystal network and is determined by the solid fat content (SFC). SFC’s temperature-dependent profile determines the applicability of edible fats and oils. Therefore, SFC is a critical quality control parameter. It also influences crystallisation behaviour, including polymorphism.

T1 provides insight into fat crystal size, polymorphism, and overall crystallisation state. It is particularly sensitive to changes in crystal packing. Studies show T1 is influenced more by crystal size and crystallinity than by morphology. In high SFC systems (>50%), denser, more ordered solids increase T1. In low SFC systems (<50%), larger crystal size correlates with longer T1. High nucleation rates create dense solid networks, reducing molecular mobility, thereby increasing T1.

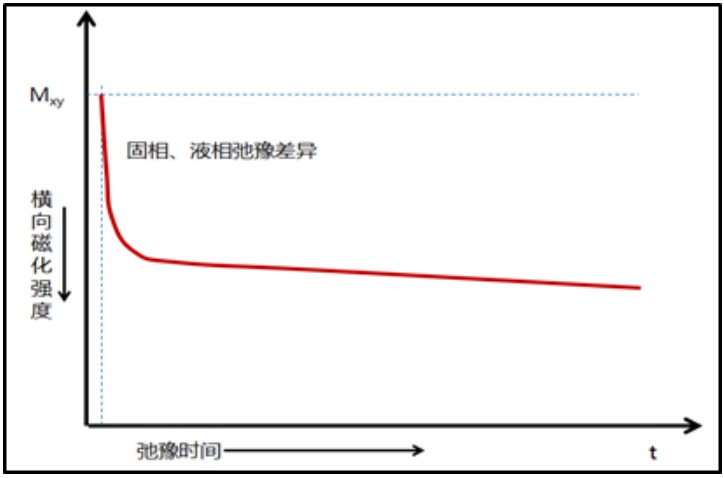

T2 is suitable for monitoring semi-solid behaviour across the entire sample. It reflects changes in spin mobility, indicating solid and liquid phase characteristics. In solids, M2 may replace T2 for better fitting. Liquid measurements typically use CPMG sequences. Although T2 is low in solids, it is sensitive to crystal rigidity and polymorphic changes. SFC is the main factor affecting T2; T2 is inversely proportional to SFC, unlike T1.

The second moment (M2) characterises proton mobility in polymorphic solids. M2 reflects dipole-dipole interactions in solid fats. Measuring M2 via TD-NMR provides insights into crystallisation kinetics and crystallinity. M2 depends on polymorphism and density but is largely insensitive to crystal size. Cooling rate significantly influences M2 values in fat-containing foods, revealing crystallinity of the system.

In the food industry, controlling fat crystallisation is crucial for the physicochemical properties of fat-based products. Time-domain NMR is a non-destructive method that monitors these changes, complementing X-ray scattering techniques to interpret fat crystallisation behaviour.

Phone: 400-060-3233

After-sales: 400-060-3233

Back to Top