With rapid societal development, food safety has become an increasingly important concern. As a staple product in our daily lives, the quality of edible oils directly impacts public health. In pursuit of profit, some unscrupulous businesses have been found refining waste oils from the food industry and mixing them into edible oils. To tackle this growing issue, we introduce a fast and simple method for detecting adulteration—Magnetic Resonance Analysis.

Waste oil from the food industry is a mixture of various plant-based oils and residual animal fats introduced through food particles. Even after refining, these adulterated oils exhibit significant changes in nuclear magnetic properties. Physically, this is reflected by a higher melting point and increased Solid Fat Content (SFC). Therefore, SFC analysis can effectively detect oil adulteration.

SFC, or Solid Fat Content, represents the percentage of protons found in the solid phase relative to the total proton count in both solid and liquid phases at a given temperature. It serves as an important indicator of fat melting behavior and firmness across different temperatures.

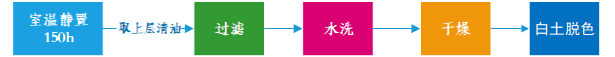

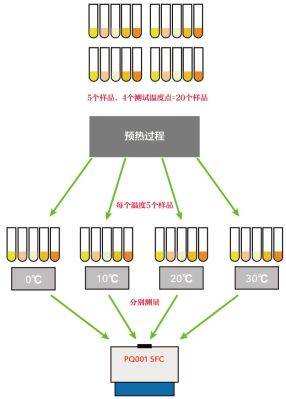

Magnetic Resonance analysis follows the standard procedure of AOCS cd 16b-93.

Principle and Calculation of SFC Measurement

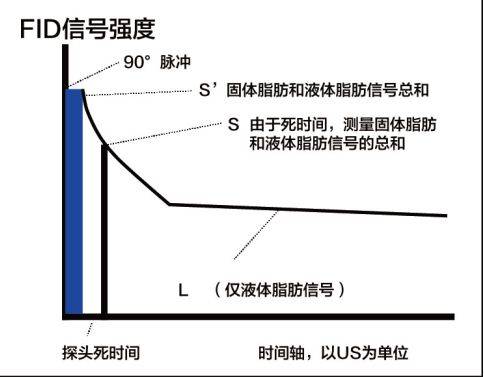

Schematic of Solid Fat Content Measurement via NMR

As shown above, in the direct SFC method, two data points from the Free Induction Decay (FID) curve are selected: one at 11 µs (E11), representing both solid (S) and liquid (L) signal; and the other at 70 µs (E70), representing only liquid signal (L). These two values are then used to calculate SFC using the following equation:

S = signal from solid fat; L = signal from liquid fat.

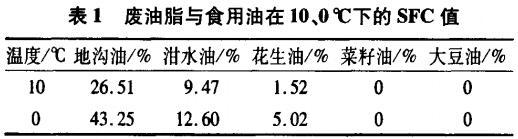

Intrinsic SFC Levels of Different Oils

As shown in Table 1, at 10°C and 0°C, the SFC values of gutter oil are 26.51% and 43.25% respectively—much higher than those of regular edible oils. Swill oil ranks next, with SFC values of 9.47% and 12.60% at 10°C and 0°C. These significant differences in SFC provide a clear basis for identifying oil adulteration.

Adulteration Detection in Soybean Oil

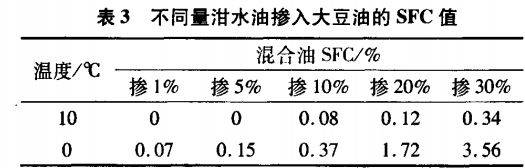

Different amounts of gutter oil and swill oil were blended into soybean oil at concentrations of 1%, 5%, 10%, 20%, and 30%. SFC values were then recorded at 10°C and 0°C.

As shown in Tables 2 and 3, SFC values increased proportionally with the addition of adulterants. At 0°C, pure soybean oil had an SFC of 0. However, with just 1% gutter oil, SFC rose to 0.18%. Similarly, with 1% swill oil, it increased by 0.07%. This proves that even 1% adulteration can be detected using Magnetic Resonance analysis.

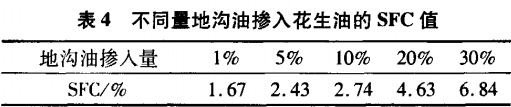

Adulteration Detection in Peanut Oil

As seen in Tables 4 and 5, pure peanut oil has an SFC of 1.52% at 10°C. With the addition of 1% gutter oil, SFC rises to 1.67%, and with 1% swill oil, it increases to 1.58%. These shifts are significant enough to confirm adulteration through magnetic resonance analysis.

References:

Wang Le, Li Yong, Hu Jianhua. Detection of Waste Oil Adulteration in Edible Vegetable Oils Using Magnetic Resonance Method [J]. China Oils and Fats, 2008, 33(10):75–77.

Recommended Instrument: Magnetic Resonance-Based Solid Fat Content Analyzer

Phone: 400-060-3233

After-sales: 400-060-3233

Back to Top