Solid Fat Content (SFC) measurement is a common and essential step in the food industry. SFC analysis is crucial for manufacturers producing fat-based foods. Traditional extraction methods for SFC determination are slow, non-reproducible, and require additional chemicals. Pulsed Nuclear Magnetic Resonance (pNMR) enables direct measurement of SFC, providing rapid and accurate results. pNMR as a method for fat and oil analysis is included in standard testing protocols such as AOCS Cd 16b-93 (revised 2000, USA), ISO 8292 (Europe), and GBT (China).

Solid Fat Content refers to the percentage of fat in the solid state at a specific temperature. SFC is a critical property that influences the appearance, flavour release, melting rate, shelf life, and stability of fat-based foods. For example, in the chocolate industry, products are formulated with an ideal SFC so that chocolate remains solid at room temperature while still delivering a “melt-in-the-mouth” experience. Understanding SFC allows food engineers to guide production processes and achieve the highest product quality.

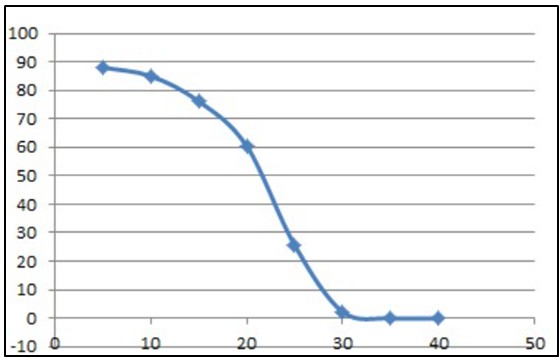

Solid Fat Content determines many key characteristics of fats, such as appearance, sensory qualities, and spreadability. SFC also affects melting behaviour, reflecting how fats behave at different temperatures. The plasticity or firmness of edible fats is largely dictated by solid content. Factors such as temperature-dependent SFC changes, melting range sharpness, and crystal morphology define the functional “plastic range” of a fat. Research indicates optimal spreadability occurs at approximately 15–35% solids, considered the plastic range. At 10°C, an SFC below 32% is critical for good spreadability, while the SFC between 4°C and 10°C determines cold temperature spreading. SFC at 25°C influences plasticity, and at 33°C affects mouthfeel.

Additionally, edible oils such as soybean and rapeseed oil are prone to oxidation, cannot be reused, and have limited shelf life. To maximise resource use, manufacturers hydrogenate oils to produce semi-solid fats. Hydrogenation increases stability for food processing but also produces trans fats. Unlike other dietary fats, trans fats provide no nutritional benefit and raise “bad cholesterol” while lowering “good cholesterol.” Health authorities worldwide recommend minimizing trans fat intake, and several countries have legislated limits on trans fat content in foods.

SFC analysis is essential for manufacturers of fat-based foods for product process optimisation, quality control, nutrition, compliance with regulations, and overall product safety.

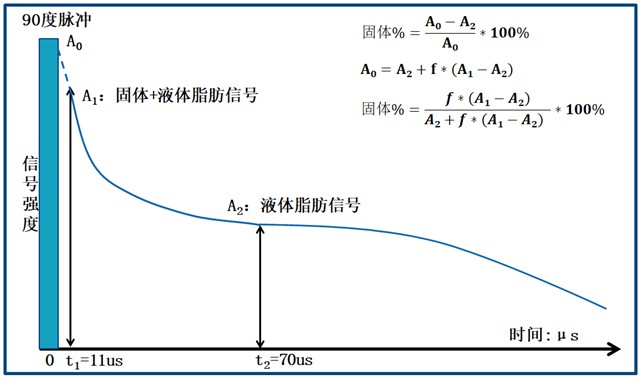

The hydrogen nuclei (H) in solid and liquid fats exist in different states, causing pulsed NMR FID signals to decay differently. Solid fat signals decay rapidly, typically reaching zero at 70 microseconds, while liquid fat signals decay much more slowly, essentially unchanged at 70 microseconds.

Because NMR signals from solids decay faster than those from liquids, measurements can be taken at two points on the FID (see figure). At t1 = 11 μs, the signal captures the sum of solid and liquid fat (A1). At t2 = 70 μs, the solid fat signal has decayed to zero, and the measured signal (A2) represents only the liquid fraction. Using these values, SFC at the test temperature can be calculated. Testing at multiple temperatures produces the SFC versus temperature curve.

Illustration of pulsed NMR measurement of Solid Fat Content

Solid Fat Content vs Temperature Curve

Pulsed NMR is the only technology that directly measures SFC. Unlike indirect methods such as Differential Scanning Calorimetry (DSC) or dilatometry, which infer SFC from melting-induced volume changes, pNMR provides direct and reliable results.

Over the years, pulsed NMR has been the preferred method for SFC determination. It is officially recognised in standard methods and offers multiple advantages over traditional techniques:

Despite requiring temperature conditioning, NMR measurements are fast (typically 6 seconds) and straightforward;

Instrument operation is simple, requiring minimal training;

NMR is non-destructive, allowing repeated measurements or additional analyses on the same sample;

Calibration is easy, and instruments are stable and reliable;

Desktop Pulsed NMR Solid Fat Content Analyser PQ001-SFC

Beef fat

Butter

Chicken fat

Coconut oil

Cream

Hydrogenated and partially hydrogenated oils

Lard

Dairy fat

Palm oil

Shortening

Margarine sticks

Phone: 400-060-3233

After-sales: 400-060-3233

Back to Top