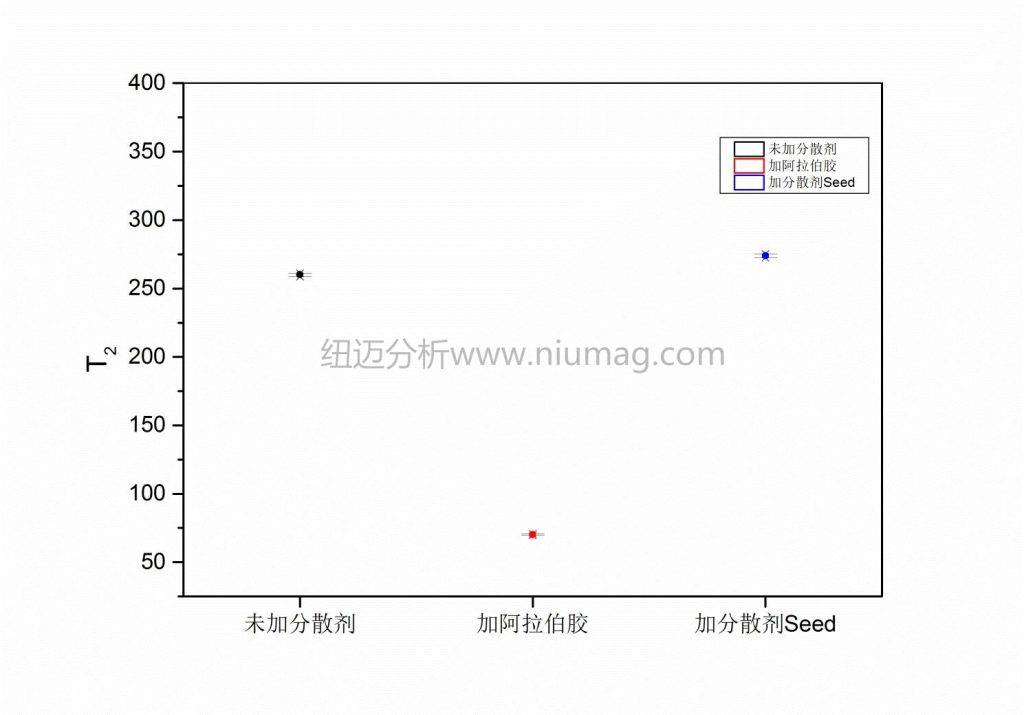

The Particle Surface Characterisation Analyzer evaluates the dispersibility of particles in a solvent by measuring their specific surface area. The larger the surface area, the better the dispersibility. Specific surface area refers to the total area in contact with the solvent (wet surface area). This method allows real-time monitoring of particle dispersibility and can also be used to assess the performance of dispersants, helping optimise slurry formulations.

Specific surface area is particularly critical for battery materials. It greatly influences slurry preparation, electrode coating, initial Coulombic efficiency, and cycling performance. Pore size also affects high-rate charge and discharge behaviour, ultimately impacting battery lifespan. For example, excessively high graphite surface area can lead to significant initial capacity loss, shortening service life. It also requires more binder, which increases internal resistance.

Battery pack manufacturing processes;

Performance of photovoltaic cell photoactive particles;

Cost control in fuel cell production

Phone: 400-060-3233

After-sales: 400-060-3233

Back to Top