Nuclear Magnetic Resonance Nanopore Analysis (NMRC) is a pore measurement technique that utilises nuclear magnetic resonance to study phase transitions of liquids within pores and characterises pore size distributions of porous materials using the Gibbs–Thomson equation. This method is suitable for a wide range of porous materials, including catalysts, filtration and adsorption media, construction materials, ceramics, biological tissues, and biomimetic materials, with a pore size testing range of 4–1000 nm. International researchers have applied NMRC to investigate liquid filling mechanisms within pores, interactions between liquids and substrate surfaces, spatial imaging of pore size distribution, and pore morphology characterisation.

1. Phase Transitions of Liquids in Pores

The Gibbs–Thomson thermodynamic equation forms the theoretical foundation of the NMRC method. It establishes the relationship between the phase transition temperature of a substance within a pore and the pore size. By selecting a suitable probe liquid, one can monitor its phase transition in the porous material to quantitatively determine the pore size distribution.

2. Freeze–Thaw Hysteresis

Similar to adsorption/desorption processes in gas adsorption methods, NMRC employs a temperature-varied approach that includes both freezing and melting processes. Due to the complex structure of pores, the critical temperatures for phase transitions between solid and liquid differ, with liquids often requiring lower temperatures than the melting point to freeze—a phenomenon known as freeze–thaw hysteresis.

This phenomenon is understood to arise from a metastable state that the liquid occupies before phase transition. Although its free energy is higher than the equilibrium state, a potential barrier exists that the liquid must overcome to undergo the phase change.

This study selected coal samples of different ranks and performed comparative experiments using NMRC freeze–thaw techniques and low-temperature nitrogen adsorption. The objective was to evaluate the feasibility and potential of using the NMRC method for quantitative analysis of coal pore volume and pore structure.

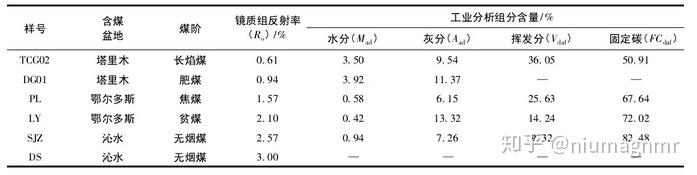

Table 1: Experimental Sample Information

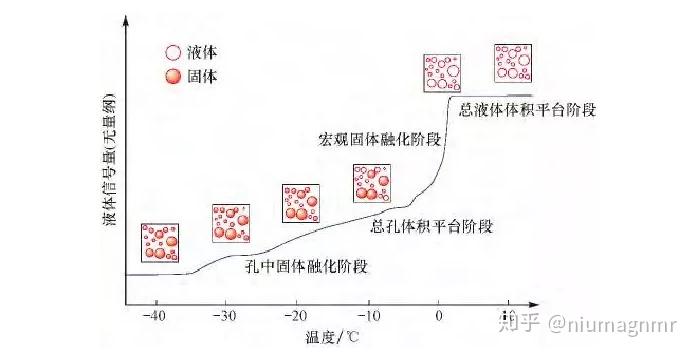

NMRC samples were ground to 20–40 mesh. The instrument used was the Newmai NMRC12-010V-T spectrometer. The system used dried, compressed air as the temperature transfer medium, a low-temperature liquid bath as the cold source, and a thermoresistor to control the dry air temperature. The main measurement relied on a stepwise temperature method to record water signals during the melting process of the sample. The resulting data was fitted to generate the I–T curve, representing the liquid signal amplitude versus temperature, as shown in Figure 1. The ideal I–T curve can be divided into four stages: pore solid melting, total pore volume plateau, macroscopic solid melting, and total liquid volume plateau.

Figure 1: Phase Transition Behaviour in Porous Materials

The pore size distribution is calculated from the I–T curve as follows: NMR signal intensity I is converted into liquid volume V; then, using a simplified equation, temperature T is converted into pore size x, yielding the cumulative pore volume below a given pore size.

1. NMRC Test Results (Instrument: NMRC12-010V Nanopore Analyser)

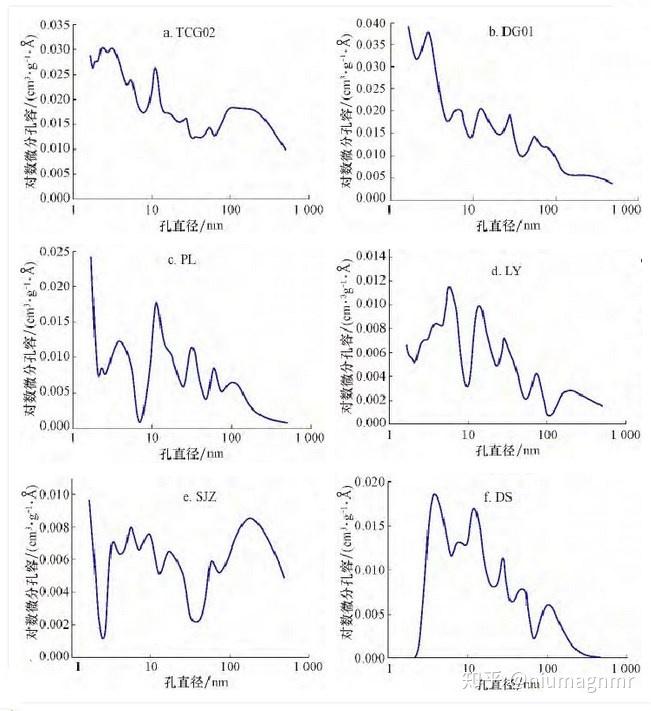

Figure 2 shows the pore size distribution of six coal samples. Overall, the lowest and highest rank coal samples (Figures 2a, 2b, 2f) feature pore size distributions decreasing gradually with increasing pore size, with clear primary and secondary porosity dominated by micropores. This suggests that coal pores may develop via “simple” or “simple–complex–simple” pathways depending on the coalification stage. Medium-rank samples (Figures 2c, 2d, 2e) show more irregular fluctuations without a clear trend.

Figure 2: NMPC Pore Size Distribution of Six Coal Samples

2. Low-Temperature Nitrogen Adsorption Results

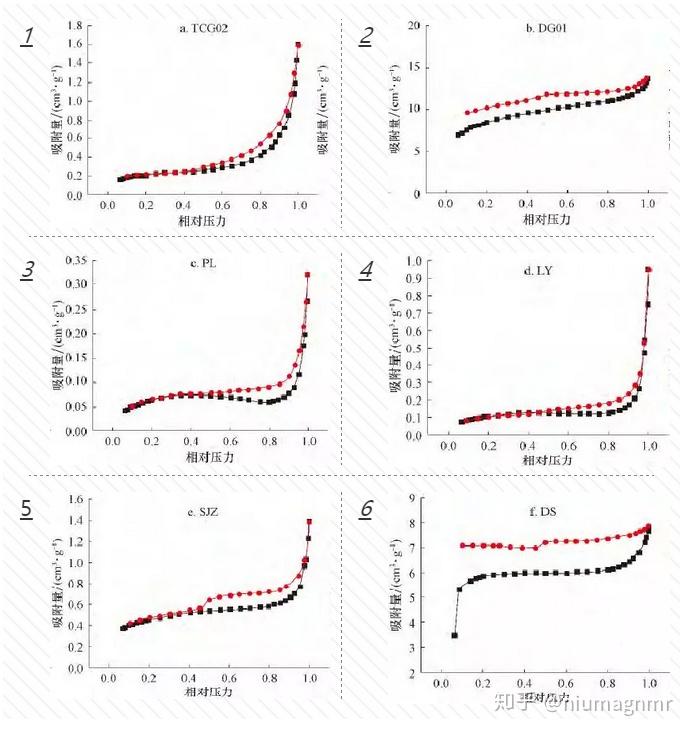

Figure 3 shows the liquid nitrogen adsorption/desorption curves for the six coal samples. According to the IUPAC hysteresis classification, Figures 3a, 3c, and 3d exhibit narrow hysteresis loops indicative of open pores; Figures 3h and 3f show parallel adsorption/desorption curves, representing closed, impermeable pores; Figure 3e features a wider hysteresis loop, characteristic of ink-bottle pores with narrow necks and wide bodies.

Figure 3: Low-Temperature Nitrogen Adsorption/Desorption Curves of Six Coal Samples

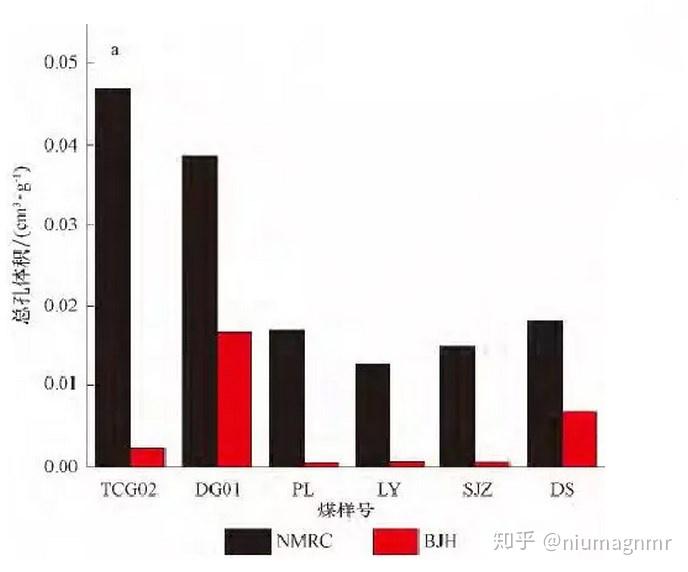

1. Comparison of Total Pore Volume

As shown in Figure 4, the total pore volume measured by NMRC is significantly higher than that obtained by low-temperature nitrogen adsorption for all samples. This can be attributed to two main factors: first, the presence of closed pores in coal samples, which often account for more than 60% of total pore volume, leading to underestimation by nitrogen adsorption; second, the effect of sample particle size, which has been shown to influence gas adsorption measurements.

Figure 4: Total Pore Volume Comparison of Six Coal Samples

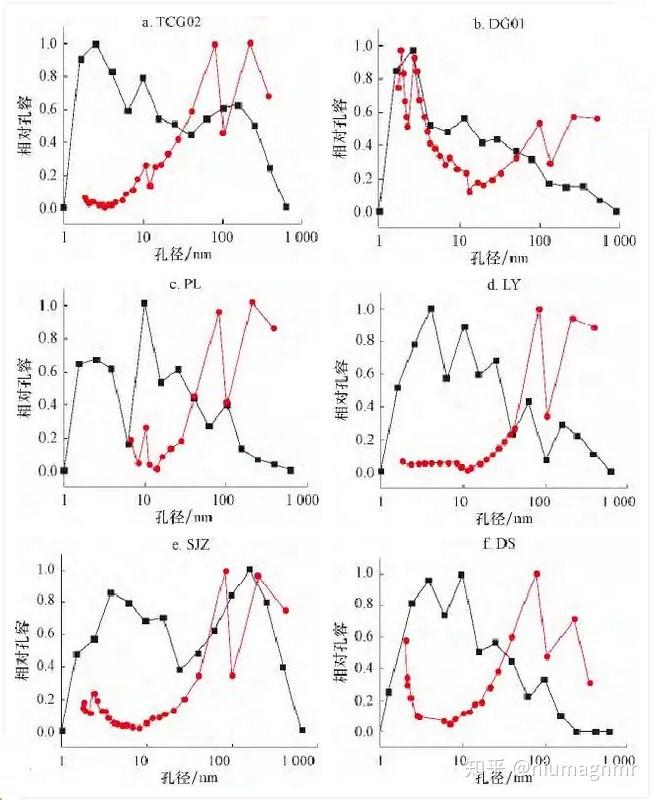

2. Stage-Wise Pore Volume Comparison

Figure 5 compares pore size distributions, with NMRC in black and adsorption in red. NMRC provides a more complete distribution across 1–1000 nm with clear peaks, enabling straightforward identification of dominant pore ranges. In contrast, low-temperature nitrogen adsorption is limited to 2–350 nm, with a single peak around 100 nm, missing some mesopore information. Micro-pore distribution differs notably between methods, while larger pores show similar distributions and peak ranges.

Figure 5: Comparison of NMPC and BJH Pore Size Distributions for Six Coal Samples

Significant differences in volume, dry sample signals, and porosity were observed before and after carbonation. Carbonation caused shrinkage in all samples, though PC samples shrank less due to Ca(OH)₂ expansion converting to CaCO₃, which increases volume by approximately 11.8%. Additionally, increasing water-glass modulus from 0, 0.5, 1, to 1.5 increased shrinkage by 7.43%, 7.67%, 9.98%, and 11.53%, respectively, likely because higher modulus C-S-H formation hinders CaCO₃ crystallisation. Hydrotalcite formation during carbonation may also interfere with CaCO₃ crystallisation.

The NMRC freeze–thaw method detects a wider variety of pore types (including open and closed pores) and a broader pore size range, providing more complete pore distribution information. This method offers clear advantages over conventional techniques, including non-destructive testing, rapid and convenient measurements, minimal sample preparation, and preservation of sample integrity, making it a promising approach for characterising unconventional reservoir porosity.

Guo Wei, Yao Yanbin, Liu Dameng, Sun Xiaoxiao, Gao Yangwen. Study on Coal Pore Measurement Based on NMR Freeze–Thaw Technology [J]. Petroleum and Natural Gas Geology, 2016, 37(01): 141–148.

Phone: 400-060-3233

After-sales: 400-060-3233

Back to Top