During fiber manufacturing, applying an appropriate amount of oiling agent is essential to ensure antistatic properties, bundling, and surface smoothness—facilitating subsequent processing. Uneven oil distribution can result in yarn irregularities and surface defects such as fuzz. Excessive oil application leads to increased production costs and waste. In spandex production, inaccurate oil content measurement can prevent correct control of the degreasing agent (CCl4) dosage and timing. Since CCl4 is highly destructive to spandex fibers, it can cause brittleness and loss of elasticity. Therefore, accurate measurement of fiber oil content is critical for quality and performance.

Traditional solvent extraction methods typically take 5–6 hours for a single test. However, chemical fiber production is fast-paced and continuous—delays in detecting quality issues can result in significant waste. Moreover, extraction methods are costly and rely heavily on chemical reagents and manual labor. In contrast, NMR (nuclear magnetic resonance) offers a fast, non-destructive, and eco-friendly solution with no need for chemical solvents. Only a small fiber sample is needed, which is placed in the probe, and results are available in just seconds. The advantages include:

1. Improved quality monitoring: Each test takes around 30 seconds, enabling real-time feedback to the production line for immediate process adjustments.

2. Lower testing costs: No chemical reagents required, reduced labor expenses, and fewer health-related insurance costs from chemical exposure.

3. Direct economic benefits: Accurate oil content measurement allows for precise oiling control, minimizing waste and maximizing efficiency.

4. Environmentally friendly: No chemical reagents are used, reducing pollution and exposure risks—helping position your brand as a sustainable and responsible manufacturer.

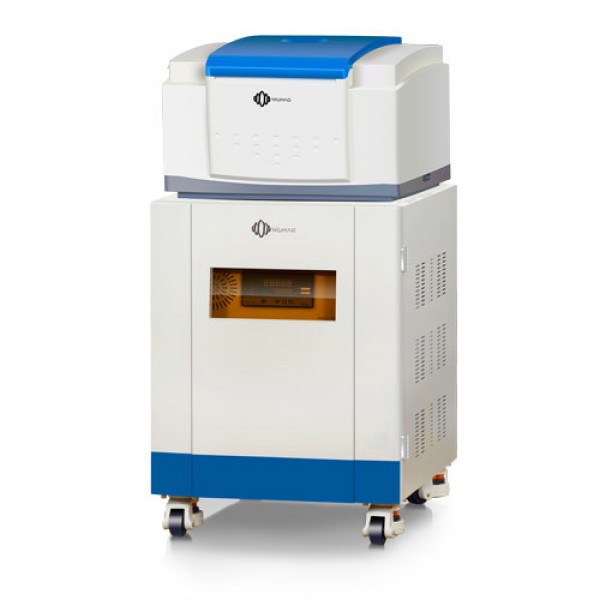

Recommended Instrument: NMR Fiber Oil Content Analyzer

Phone: 400-060-3233

After-sales: 400-060-3233

Back to Top