Injection rate is a critical factor influencing the effectiveness of hydraulic fracturing. However, its impact on pore and fracture structures (PFS) and on fluid infiltration during pressurised water injection remains underexplored. In this study, cylindrical sandstone specimens were fractured using a self-developed integrated NMR and hydraulic fracturing platform under varying injection rates. The findings revealed that low injection rates mainly induce macropore-scale damage, while high rates trigger micropore-scale damage—possibly due to clay mineral swelling within pores. Water content increased continuously under low injection rates, but stabilised after initial rise in high-rate scenarios. MRI showed strong anisotropy in fluid migration due to non-uniform PFS around the borehole. A primary flow path aligned with the hydraulic fracture initiation direction was consistently observed. Interestingly, damage propagation along this direction decreased with increasing injection rate, while perpendicular damage propagation remained constant. These insights support the use of pore-scale damage characteristics in selecting proppant sizes and leveraging major fluid migration paths to predict fracture initiation. The study offers valuable design strategies for hydraulic fracturing in tight gas reservoirs.

Engineering Challenge: In global shale gas development, the efficiency of hydraulic fracturing is often hindered by uncontrollable rock damage mechanisms.

Core Paradox: Conventional theory assumes that increasing injection rate reduces breakdown pressure. However, field data frequently exhibit anomalous high-pressure behaviour.

Technical Strengths:

NMR enables non-destructive, three-dimensional quantification of fluid within rock pores and fractures. It offers simultaneous measurement of fluid transport and damage progression, which current tools cannot deliver.

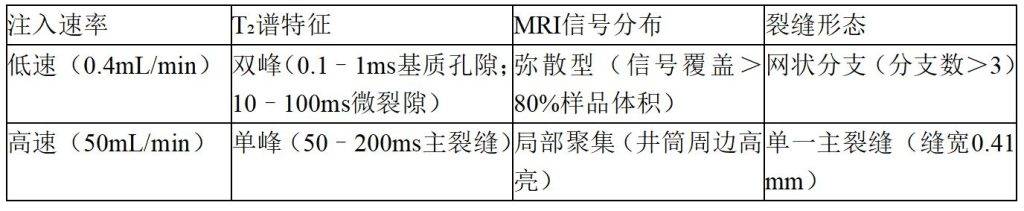

T₂ relaxation times differentiate microfractures (T₂ > 10 ms) from matrix pores (T₂ < 10 ms).

Pain Point Addressed: Traditional methods like acoustic emission or strain gauges are inadequate for tracking infiltration-induced cumulative damage.

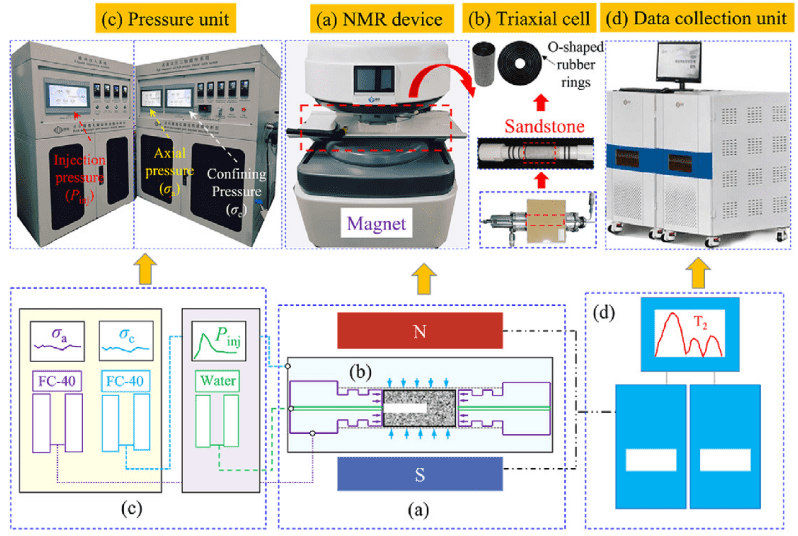

Multi-scale Observation: Integration of NMR (pore scale) with real-time hydraulic fracturing data (macro scale) offers holistic insights (see Fig. 2).

Mechanistic Breakthrough: Introduced the “Permeability-Driven Damage (PDD)” model to explain the non-linear fracture response to injection rate.

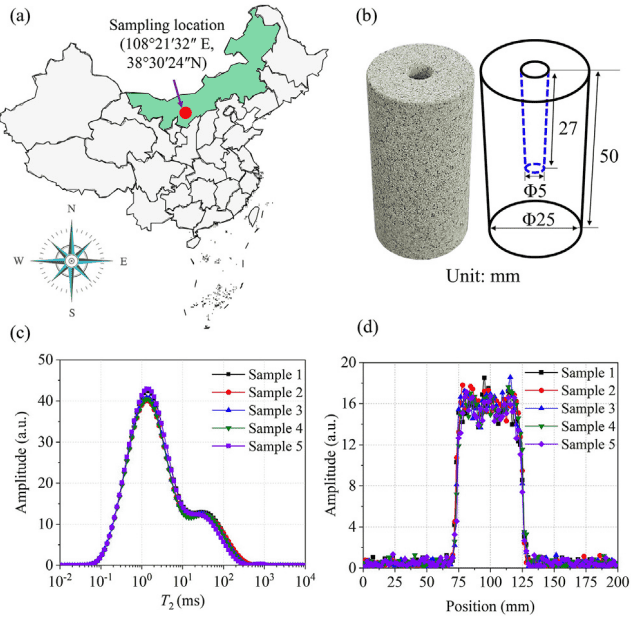

2.1 Sample Preparation and Selection

Sample Specs: Sandstone sourced from Shaanxi, China (Φ5×50 mm).

Homogeneity Assurance: Specimens with T₂ spectrum standard deviation > 5% across layers were excluded.

Figure 1. Sandstone sample preparation and homogeneity evaluation

2.2 Experimental Workflow

1. Initial Scan: NMR used to obtain baseline T₂ spectrum of dry sample.

2. Fracturing Phase: Deionised water injected at controlled rates. NMR acquired T₂ spectra every 10 seconds.

3. Post-Fracture Analysis: CT imaging captured fracture morphology; NMR data compared against observed damage.

Figure 2. NMR testing system

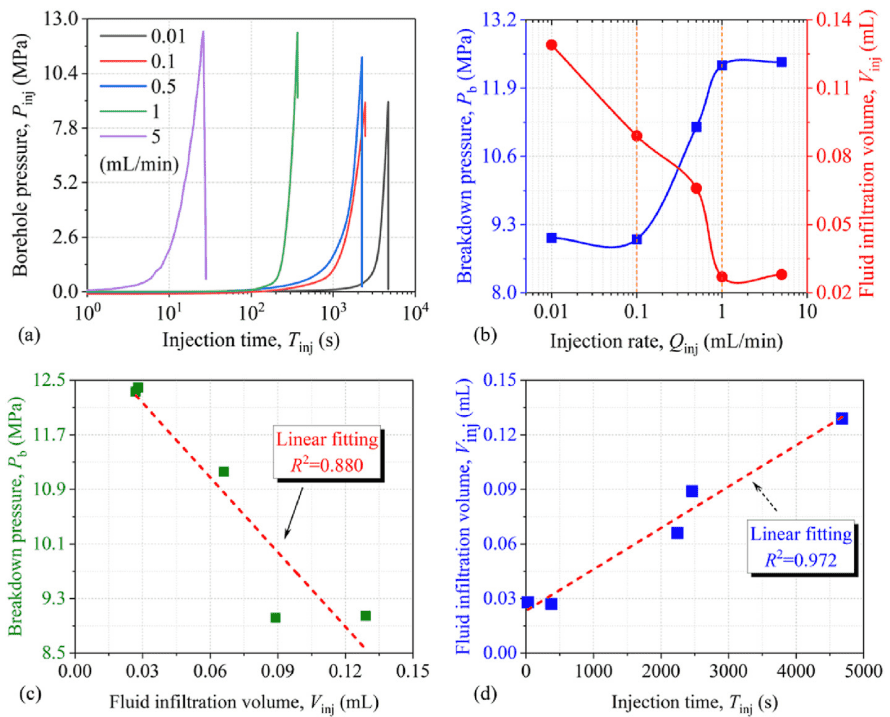

Key Insight: The relationship between injection rate and rock failure is not linear—it exhibits a distinctive U-shaped response curve.

Figure 3. Hydraulic fracturing results under varying injection rates

Non-linear Behaviour Confirmed:

Pb vs. Qinj follows a U-shaped trend:

• Low rate zone (Qinj < 5 mL/min): Pb drops from 38.2 MPa to 27.3 MPa—a 28.6% reduction—due to hydration weakening the rock matrix.

• High rate zone (Qinj > 20 mL/min): Pb rebounds sharply to 38.6 MPa—a 41.3% increase—caused by rapid fluid inertia and localised energy accumulation.

Critical Role of Infiltrated Volume (Vinj):

A strong negative correlation exists: Pb = -1.05Vinj + 42.3 (R² = 0.880), proving fluid volume—not just rate—is the driving factor in fracture onset.

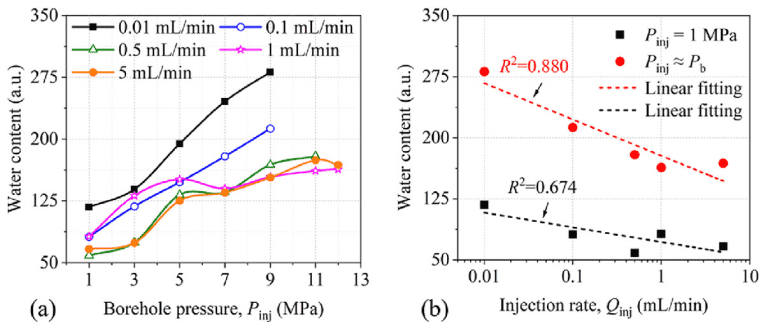

Empirical Evidence: Direct measurement of water content evolution under real-time fracture conditions.

Figure 4. Water content evolution during pressurised injection

Time–Volume Linear Law: Vinj = 0.86Tinj + 1.2 (R² = 0.972), showing injection time directly governs infiltration volume.

Water Content Trends:

• At low injection rate (0.01 mL/min): Gentle slope—fluid evenly penetrates porous matrix.

• At high rate (5 mL/min): Steep slope—rapid local saturation with limited radial spread.

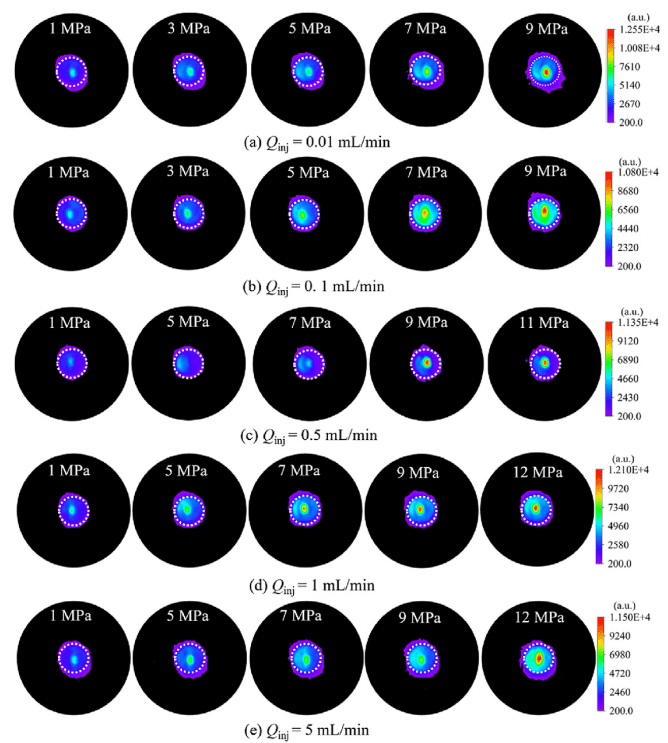

Three-Dimensional Damage Mapping: MRI signal intensity used to visualise spatial distribution of infiltration-induced damage.

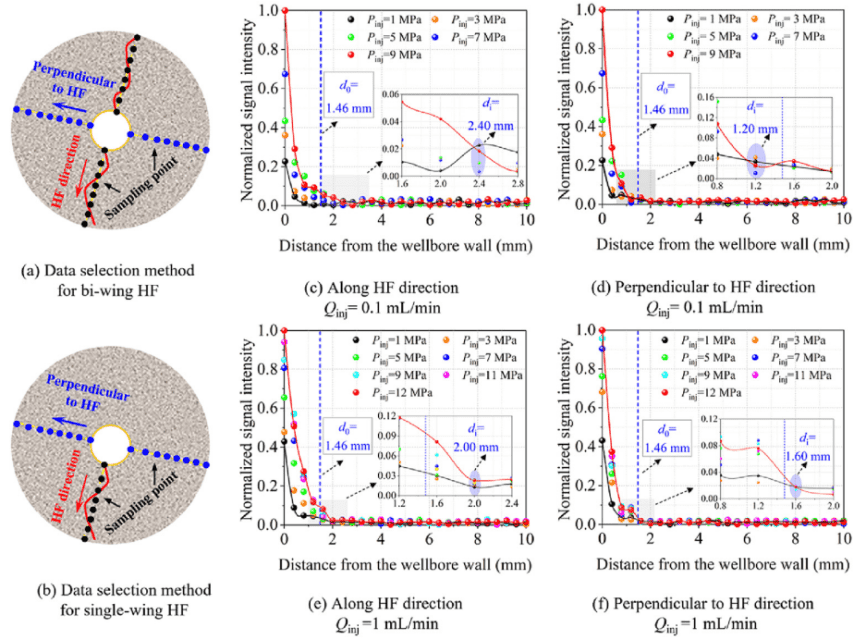

Figure 5. Normalised MRI signal profiles in and across fracture direction (HF) at various injection rates

Interpretation:

• Low injection rate yields widespread radial diffusion (penetration > 4 mm), triggering multiple branching fractures.

• High injection rate results in localised damage—MRI high-signal region (> 200 a.u.) covers only ~15% of sample, inhibiting secondary fracturing.

Figure 6: Volumetric NMR Damage Map

Figure 6. NMR-based spatial damage characterisation of fractured rock

Low Injection Rate: NMR signals indicate full-sample penetration (blue areas > 80% coverage); micro-CT confirms multi-branch fractures.

High Injection Rate: Fluid confined to central region (highlighted red zone); micro-CT reveals a single dominant fracture with width > 0.4 mm.

The NMR-integrated workflow has delivered three major breakthroughs in this study:

1) Quantification of Permeation Volume: A clear correlation is established between injected volume (Vinj), injection time, and breakdown pressure. This quantitative relationship empowers predictive control of fracture initiation.

2) Damage Mode Characterisation: Analysis of T₂ peak shape transitions reveals a dynamic evolution from homogenous microdamage to localised macrofracture, enhancing our understanding of failure mechanisms.

3) 3D Spatial Localisation: Fluid distribution maps derived from NMR enable accurate visualisation and prediction of fracture geometry—crucial for optimisation of field-scale fracturing strategies.

Future Perspective: Embedding NMR-derived damage models into hydraulic fracturing simulation software can pave the way for intelligent geo-engineering design with real-time adaptive control.

Large-Bore NMR Imaging System for Fracture and Pore Structure Analysis

Interested in this application? Reach us directly at: +86 15618820062

[1] Long A, Zhang Y, Zhao Y, et al. Damage evolution characteristics caused by fluid infiltration across diverse injection rates: Insights from integrated NMR and hydraulic fracturing experiments. Journal of Rock Mechanics and Geotechnical Engineering. 2025-06-18.

Phone: 400-060-3233

After-sales: 400-060-3233

Back to Top