In late 2021, UPM-Kymmene, a Nordic-based biobased materials and bioenergy company, announced the launch of UPM BioMotion™ RFF—a “new to the world” renewable filler technology. According to its patent[1], the technology separates lignocellulose particles and lignin particles from crude lignin. The lignocellulose can be used to produce bioethanol (see article: “LF-NMR Technology for Evaluating Bioethanol Production Process”), while the lignin is subjected to hydrothermal carbonization to obtain lignin-derived materials[2]. These materials are rich in carbon and functional groups, allowing them to enhance the performance of rubber-based products such as tires—serving as a sustainable alternative to traditional carbon black.

On June 27, 2024, UPM announced on its official website that it had partnered with Finnish tire manufacturer Nokian Tyres to replace 30% of the reinforcing carbon black in tire sidewalls with UPM’s lignin-based filler material using RFF technology. This marks a significant step toward replacing fossil-based materials with biobased alternatives, reducing carbon emissions and lowering the carbon footprint of industrial manufacturing.

Carbon black is a common reinforcing agent used in tires to improve the mechanical strength and wear resistance of rubber and other elastomers. It is one of the most widely used filler materials in the rubber industry, typically accounting for around 15% of material costs. However, carbon black production contributes to environmental issues such as greenhouse gas emissions, air pollution, water contamination, and solid waste. A new national standard, GB 29449-2024 “Energy Consumption Limits per Unit Product for Tires and Carbon Black,” will take effect on May 1, 2025, further restricting carbon emissions.

Amid growing environmental pressures and evolving regulations, lignin has emerged as a highly promising biobased alternative to carbon black in sustainable rubber manufacturing.

Large-scale replacement of carbon black with lignin will inevitably lead to changes in rubber processing techniques.

Crosslink density is one of the most critical parameters for evaluating the performance of rubber and other polymer materials. It is widely used in process control and formulation studies, including optimizing vulcanization time, temperature, and curing agent selection. In this context, LF-NMR provides real-time support for adjusting curing conditions when replacing carbon black with fillers like silica or lignin—or even blended systems.

During vulcanization, the rubber transforms from a 2D linear molecular structure to a 3D network. As a result, its crosslink density changes significantly. Nuclear magnetic resonance (NMR) is capable of capturing the microstructural changes associated with this transition and offers advantages such as fast measurement cycles and high repeatability.

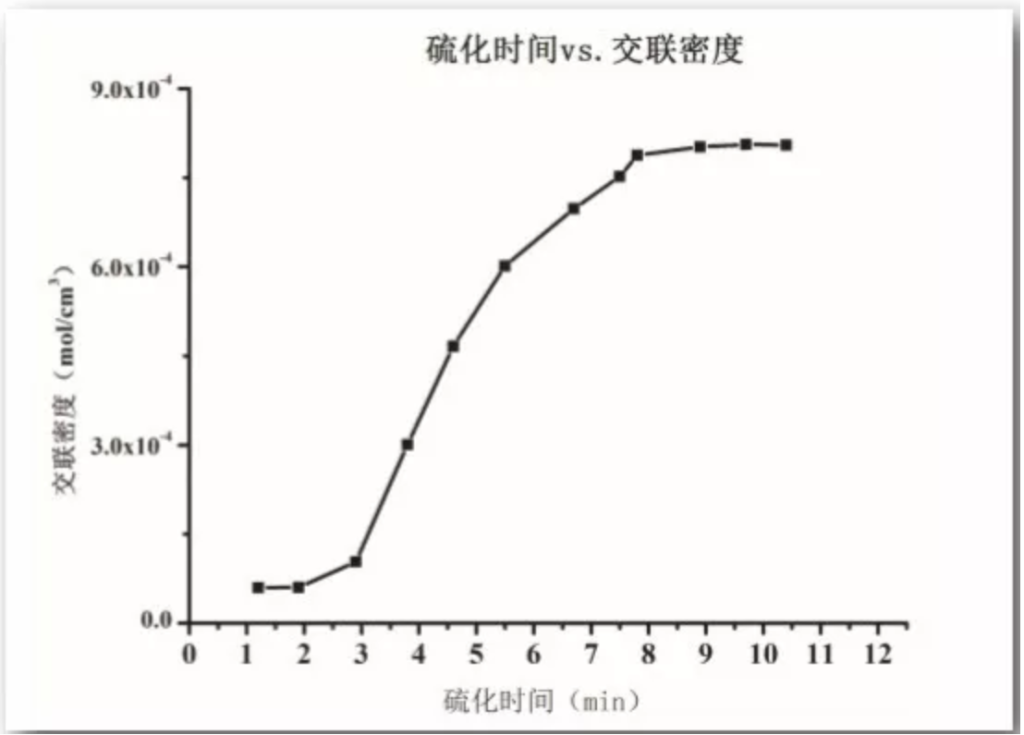

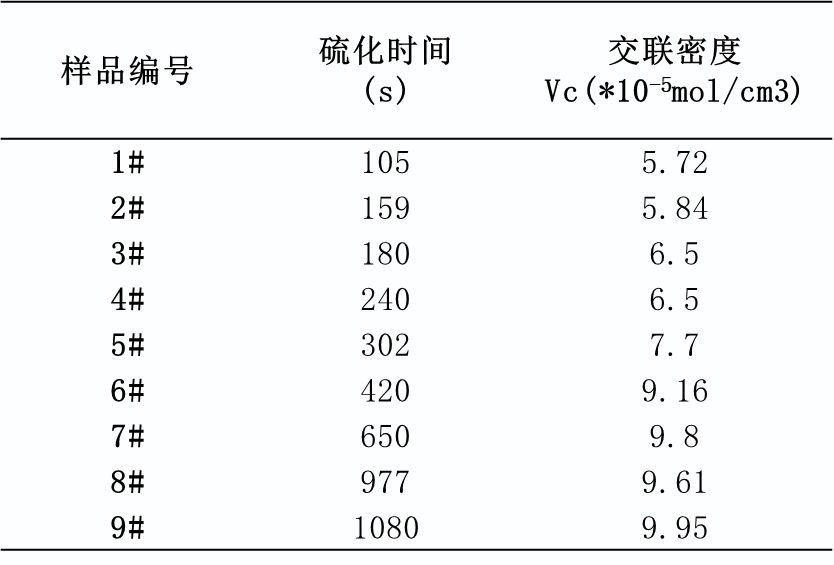

The graphs above were obtained under Tg+150°C conditions. At this elevated temperature, intermolecular forces are eliminated, allowing accurate characterization of crosslink density (both physical and chemical) throughout the vulcanization process.

Using NMR to monitor crosslink density in real time during vulcanization—alongside online temperature and time control—offers precise insight into the dynamic evolution of crosslinking. This enables smarter control of rubber curing processes and optimized manufacturing parameters.

As a renewable, biodegradable, and biocompatible biobased material, lignin plays a critical role in reducing environmental impact. However, large-scale adoption also calls for improved process control. Low-field NMR offers a green, rapid, and non-destructive solution for measuring rubber crosslink density—making it a valuable tool for optimizing vulcanization processes and ensuring high-performance, sustainable rubber production.

If you’re interested in this application, feel free to contact us: 15618820062

[1] Miettinen, Mauno. “METHOD AND APPARATUS FOR SEPARATING LIGNOCELLULOSE PARTICLE FRACTION AND LIGNIN PARTICLE FRACTION, LIGNIN PARTICLE COMPOSITION, LIGNOCELLULOSE PARTICLE COMPOSITION AND THEIR USE.” U.S. Patent No. US11,066,525B2, July 20, 2021.

[2] Lahtinen, Mika et al. “TYRE COMPRISING HYDROTHERMALLY CARBONIZED LIGNIN.” U.S. Patent No. US10,428,218B2, October 1, 2019.

Phone: 400-060-3233

After-sales: 400-060-3233

Back to Top