The water resistance of polymeric materials—such as rubber, plastics, and resins—plays a critical role in determining their service life and performance stability.

Traditional evaluation methods—such as gravimetric analysis—are simple to operate but offer only a rough estimation of water resistance. They cannot reveal internal structural changes or molecular mobility within the material.

Emerging techniques like terahertz spectroscopy and dielectric analysis show certain advantages, yet they also come with limitations. For example, both methods offer a typical detection accuracy of ±0.5%, which may be insufficient when water absorption is below 1%, rendering the results less meaningful.

Furthermore, terahertz signals are heavily absorbed by strongly polar groups (e.g., in nylon), resulting in severe signal attenuation and increased measurement error. Dielectric analysis requires direct electrode contact, where oxidation or interfacial effects may also compromise accuracy.

This case study explores the use of low-field NMR to evaluate the water resistance of foam resins—offering new insights and characterisation strategies for material scientists.

In portable electronic devices, impact-absorbing materials are often required to possess excellent water resistance. In this study, several foam resins were evaluated, with low-field NMR used as the primary characterisation tool.

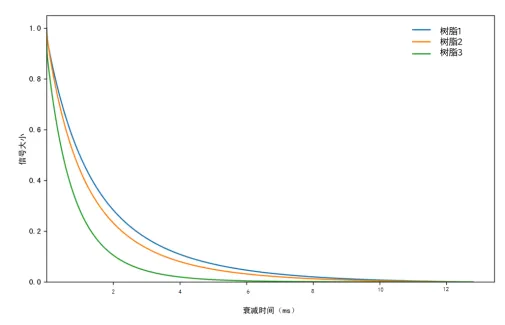

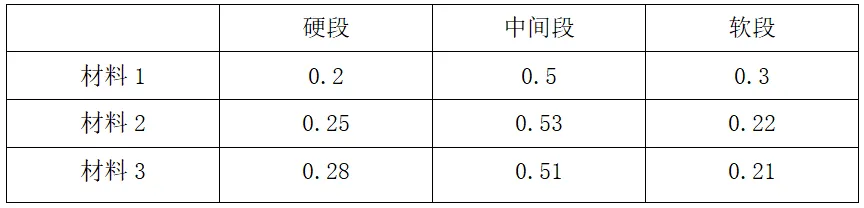

Initially, relaxation curves for three foam resins were tested (as shown below), and component analysis was conducted via inversion to extract the hard, intermediate, and soft segment distributions.

Next, the foam resins were immersed in heavy water (D₂O), which, due to its higher density, more effectively simulates harsh environmental conditions and accelerates water-induced swelling. (Regular water can also be used for soaking.)

After soaking for one day, the relaxation behavior was retested to assess how the hard and soft segment ratios evolved.

The water resistance of a material primarily depends on two factors:

1. The proportion of hard segments within the material;

2. The degree of change in soft segment content before and after heavy water immersion.

In general, the higher the hard segment content and the smaller the variation in soft segments post-soaking, the better the material’s water resistance.

To quantify this, the study proposes an indicator “N” to evaluate water resistance: N = (Hard Segment Ratio before soaking) × (Soft Segment Ratio before soaking / Soft Segment Ratio after soaking). A higher N value indicates superior water resistance. Based on this metric, Resin 3 demonstrated the best performance.

Additionally, with the VTMR20-010V-I variable temperature NMR device, it’s possible to study the evolution of material performance during repeated wet-dry cycles.

This application leverages low-field NMR technology for evaluating resin water resistance because it offers direct insight into the material’s internal structure and molecular mobility—providing a deeper understanding of waterproof performance at the molecular level.

Phone: 400-060-3233

After-sales: 400-060-3233

Back to Top