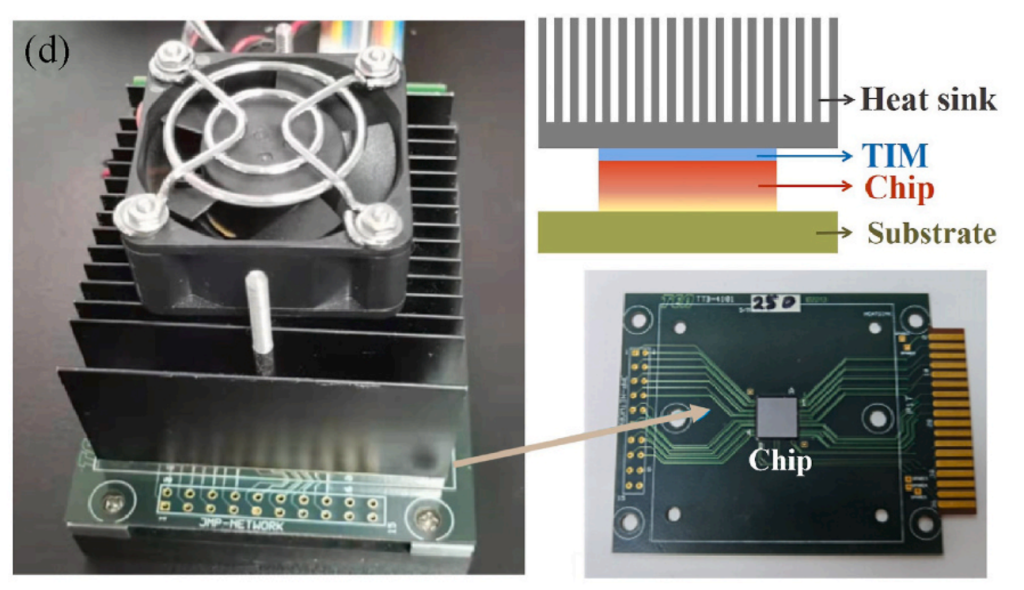

As chips continue to evolve toward miniaturization and higher integration, thermal management becomes critically important for enhancing overall device performance. Due to surface roughness mismatches between chips and heat sinks, air gaps can form and result in significant thermal resistance. Thermal interface materials (TIMs) are used to fill these gaps and reduce resistance (Figure 1). In practical use, TIMs must exhibit high thermal conductivity. Compared to metal- and carbon-based TIMs, polymer-based TIMs remain the most widely adopted materials for chip cooling due to their low cost, ease of processing, and high reliability.

However, as chip sizes increase and warpage becomes more severe, TIMs not only require excellent thermal conductivity but also good flexibility. Unfortunately, thermal conductivity and flexibility are often negatively correlated in polymer-based TIMs—achieving high conductivity typically requires a high filler content, which compromises mechanical flexibility.

In this study, Prof. Xiaoliang Zeng’s research group at the Shenzhen Institute of Advanced Technology, Chinese Academy of Sciences, developed TIMs composed of functionalized polydimethylsiloxane (PDMS) and aluminum (Al) powder by introducing pendent chains into the PDMS network. These pendent chains reduce intermolecular interactions and chain entanglement. The study investigated how pendent chain content affects the flexibility of PDMS-based TIMs, offering a practical strategy for designing flexible, high-performance TIMs for chip cooling.

Figure 1: Schematic of a chip-based system

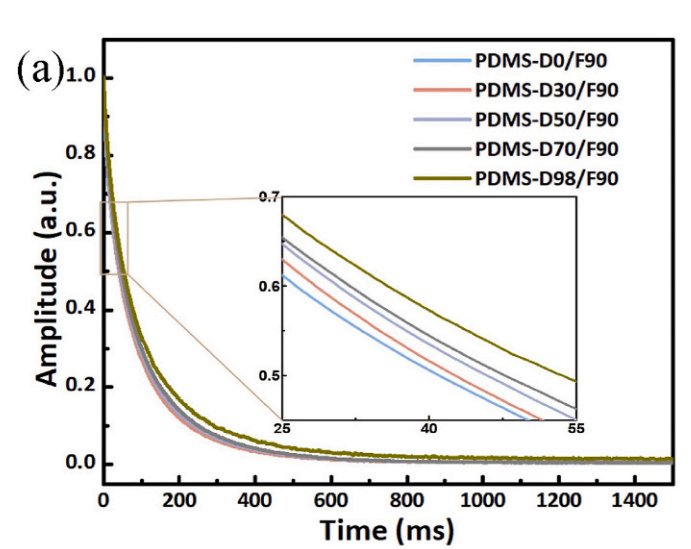

Figure 2: T2 relaxation times of polymers with varying pendent chain content

The team used the VTMR20-010V-I low-field NMR system from Niumag Analytical Instruments to measure the T2 relaxation times of polymers with different levels of pendent chains. As shown in Figure 2, the T2 relaxation time increases with pendent chain content, indicating that more pendent chains enhance polymer chain flexibility.

The research group proposed a strategy of introducing pendent chains into polymer networks, resulting in TIMs with both high thermal conductivity (4.50 W/m·K) and outstanding flexibility (elongation at break: 104%, Young’s modulus: 0.24 MPa). Low-field NMR played a key role in characterizing these properties.

If you’re interested in this application, feel free to contact us: 15618820062

Yongdong Wu, Chenxu Zhang, Wendian Tu, Guoping Du, Xiaoliang Zeng, Rong Sun, Yonglun Xu, Linlin Ren, Compliant thermal interface materials via introducing pendent chains into polymer networks for chip cooling, Composites Communications, Volume 37, 2023, 101452.

Phone: 400-060-3233

After-sales: 400-060-3233

Back to Top