With the rapid development of industrialisation and urbanisation in China, the amount of solid waste being generated continues to rise, making effective and responsible disposal a critical challenge of our time.

In most Chinese cities, solid waste treatment is primarily carried out through landfill and incineration, both of which are increasingly associated with environmental concerns. For example, landfill sites require vast amounts of land, while incineration may release toxic gases and fly ash. In response, China has actively promoted waste reduction, segregation, and resource utilisation policies, aiming to increase recycling rates and reduce overall waste emissions [1].

Low-field nuclear magnetic resonance (NMR) has emerged as a powerful analytical tool widely used in energy and geotechnical applications. It has proven particularly effective in characterising internal structures, assessing moisture content and distribution, monitoring dynamic migration, and analysing in-situ damage or crack development.

The advancement of solid waste recycling and the circular economy demands the development of new functional materials. Applications include cement blending with tailings, solidification of waste, coal gangue crushing and soil modification, and sludge stabilisation.

Low-field NMR provides rapid, non-destructive testing at the macro scale and enables microstructural characterisation. As such, it plays an instrumental role in supporting solid waste treatment technologies [2].

Low-field NMR was applied to monitor the solidification process of cement-stabilised sludge [3], yielding the following conclusions:

1. Within the first 7 days, a significant portion of pore water rapidly transforms into chemically bound water, contributing to the formation of the pore framework. After 7 days, hydration slows, and the skeletal structure undergoes only slight changes.

2. The hydration reaction is more extensive when the cement dosage is lower.

3. Based on the hydration model proposed, once the NMR parameter Mhw is determined, permeability, strength, and deformation parameters can be derived—offering theoretical support for practical engineering design.

Coal gangue contains a measurable amount of hydrogen, which enhances the mechanical properties of construction materials. The hydrogen content plays a critical role in determining the final strength.

Raw coal gangue sample

Coal gangue bricks

Samples of coal gangue were tested for hydrogen content using NIUMAG low-field NMR. After signal normalisation, hydrogen content was calculated via the calibration curve. The measured hydrogen levels for each sample are presented below:

The results enable rapid screening of hydrogen-rich coal gangue for use in manufacturing high-strength construction materials.

This case integrates mechanical loading with NMR to investigate triaxial stress–strain responses of coal samples. Using NIUMAG’s pseudo-triaxial NMR system, both mechanical and NMR observations can be synchronised in situ during compression [4].

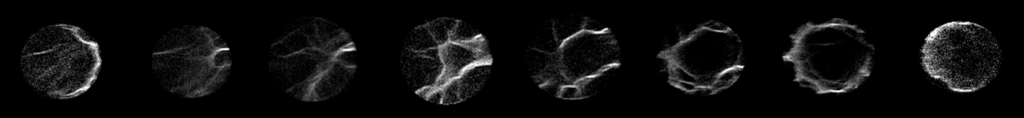

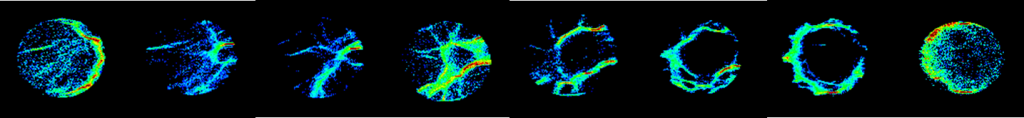

Stress–strain characteristics and NMR imaging of three coal samples

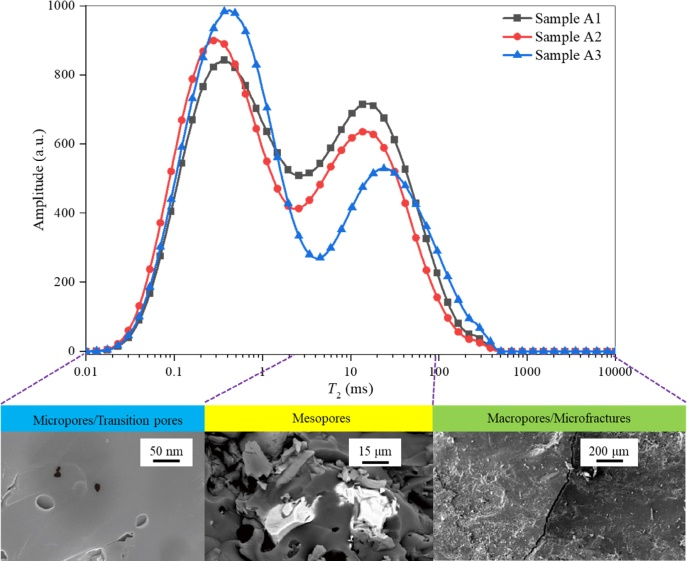

T2 distribution and pore classification under hydrostatic conditions

The combined mechanical–NMR testing yielded the following insights:

The peak strength values of the three samples were 49.5 MPa, 47.2 MPa, and 45 MPa, with maximum strains of 3.59%, 3.7%, and 3.47%, respectively. NMR imaging visualised the water distribution evolution during loading — warmer tones indicate higher moisture concentration.

The T2 spectrum under hydrostatic pressure enabled pore classification: T2 < 2.5 ms corresponds to micropores and transitional pores; 2.5 ms < T2 < 100 ms to mesopores; and T2 > 100 ms to macropores and micro-fractures.

With both mechanical and NMR data, the evolution of pore–fracture systems (PFS) was characterised, allowing the development of compressibility models and accurate descriptions of pore sensitivity to stress.

Geotechnical samples were subjected to triaxial stress damage analysis using a pseudo-triaxial NIUMAG low-field NMR system. Below are the applied axial load pressure profiles and the corresponding porosity variation curves [5].

Comparison of NMR imaging under different loading conditions

As axial pressure increases, the number of micro-cracks increases significantly, leading to progressive structural damage.

When the axial stress is less than 90% of the rock’s triaxial compressive strength, damage in marble is primarily due to an increase in the number of small internal pores.

Once axial stress exceeds 90% of the triaxial compressive strength, damage escalates rapidly, culminating in failure — this is attributed to both the increased number of internal fractures and the widening of existing cracks.

[1] Ling Jiang, Sun Jingnan, Liu Gang. Enhancing Solid Waste Treatment Capacity and Promoting Resource Utilisation — Policy Analysis in the Recycling Industry [J]. Environmental Protection, 2017(20):10-15.

[2] Haijun He, Xi M, Jian T, et al. Event-triggered-based self-organising fuzzy neural network control for municipal solid waste incineration [J]. Science China: Technological Sciences, 2023.

[3] Wang Shiquan, Wei Mingli, He Xingxing. Study on Water Transformation Mechanism of Sludge Solidification Based on NMR [J]. Rock and Soil Mechanics, 2019(5):1778-1786.

[4] Zhou Hongwei, Liu Zelin, et al. In-situ Observation and Modelling Approach to Pore-Fracture Evolution in Coal [J]. International Journal of Mining Science and Technology, 2023.

[5] Zhou Keping, Hu Zhenxiang, Gao Feng. Triaxial Compression Damage Mechanism of Marble Based on NMR [J]. Rock and Soil Mechanics, 2014, 35(11):3117-3122.

Phone: 400-060-3233

After-sales: 400-060-3233

Back to Top