Gel candies are soft, chewy confections typically made from syrup and gel-forming agents such as gelatin to create their characteristic texture. Common types include gummy candies, fruit jellies and jelly desserts. In 2021 China’s State Administration for Market Regulation published the Technical Requirements and Dosage Forms for Health Food Filing (2021 edition)[1], formally recognising powder and gel-candy formats for health-food filing. Since then, gel candies have gained traction as a format for functional foods.

Low-field NMR (LF-NMR) is a green, non-destructive analytical technique that delivers fast, continuous measurements and is widely used in the food industry. It provides valuable insights into gel-candy quality and safety. For example, by measuring relaxation times and proton-density images[2], LF-NMR reveals water distribution and dynamics in samples, evaluates how different drying times affect water states, and can be used to determine glass transition behaviour (Tg) or to study how small sugar molecules influence hygroscopicity in model systems[3].

The Pharmacopoeia of the People’s Republic of China describes solid materials as either crystalline (ordered) or amorphous (non-crystalline). Crystallinity is typically assessed using methods such as powder X-ray diffraction (XRD)[4]. In gel-candy research, however, crystallinity is more complex than in pharmaceuticals: while active pharmaceutical ingredients often require exact crystallinity metrics for quality control and consistency, confectionery prioritises sensory quality — taste, texture and mouthfeel — and tends to focus on qualitative comparisons and process understanding rather than absolute crystallinity numbers. For R&D it is usually sufficient to compare samples made from different syrups to determine whether they differ in crystallinity, rather than calculating an exact degree of crystallinity for each sample — an XRD-based workflow with complex sample preparation would be too time consuming for routine, comparative screening.

In polymer science, LF-NMR methods are already established for probing crystallinity and molecular mobility. The Magic Sandwich Echo (MSE) sequence is often used to study polymer mobility and crystallisation; it refocuses the initial part of the free-induction decay (FID) to recover signals lost during dead time and allows direct measurement of solid samples without correction factors[5].

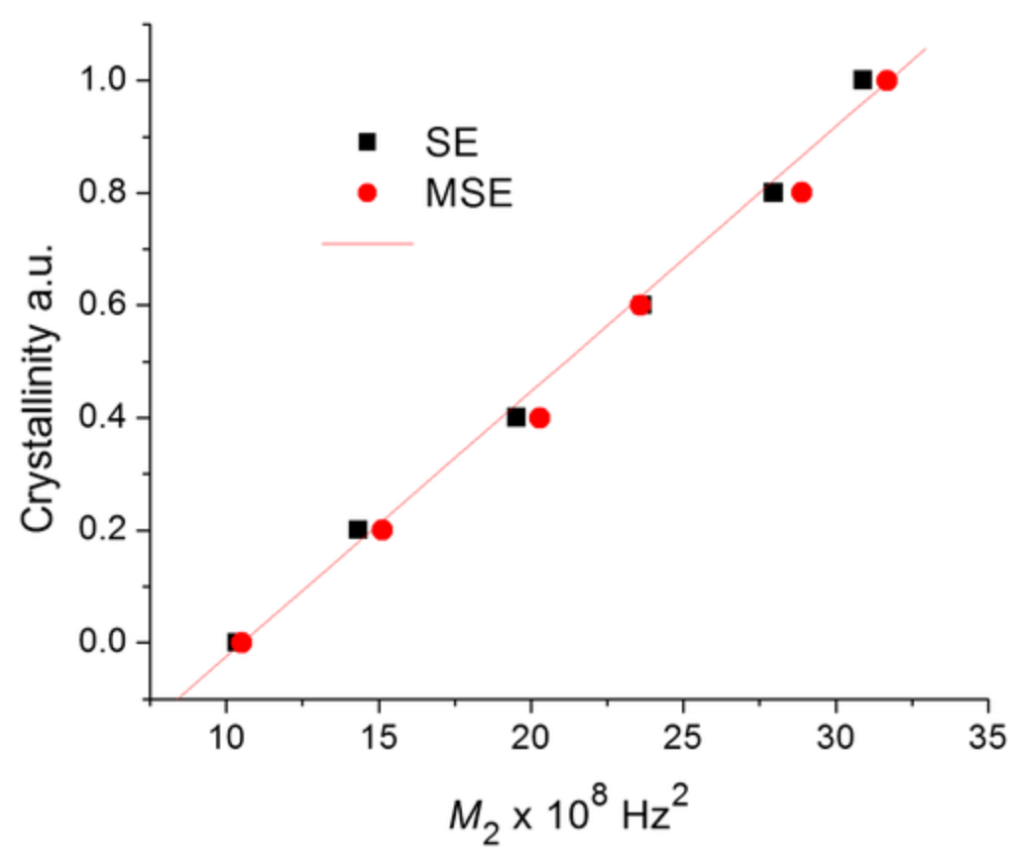

Adapting the MSE approach, LF-NMR can be applied to different gel-candies as an alternative or complementary technique to XRD for crystallinity screening. A practical workflow is to build a calibration curve: prepare reference materials (for example dried crystalline sucrose as a crystalline standard and freeze-dried sucrose as an amorphous standard) and mixtures of known proportions. By correlating the second moment (M2) or related metrics from MSE with crystallinity, one can establish a linear relationship; studies report strong agreement between SE and MSE derived measures and crystallinity (SE R2=0.995, MSE R2=0.994)[6]. Comparing LF-NMR metrics with XRD yields moderate to strong correlation (r=0.67, p<0.05)[7], making LF-NMR an effective qualitative screening tool for confectionery R&D.

For crystallinity screening, the solid-echo/MSE-based LF-NMR approach shows strong correlation with crystallinity metrics and offers a much faster, less labour-intensive alternative to full XRD characterisation. As LF-NMR becomes more accessible in food research labs, cross-disciplinary methods like this are likely to gain popularity for routine R&D and process control.

If you are interested in applying these methods, please contact: 15618820062

[1] Announcement of the State Administration for Market Regulation on the publication of “Technical Requirements and Permitted Excipients for Health Food Filing (2021 edition)” and “Dosage Forms and Technical Requirements for Health Food Filing (2021 edition)”, 2021-1613802189653.

[2] Sun W., Yan J., Lai B., et al. Development and characterization of gel candies loaded with melatonin and goji powder. Food Industry Science and Technology, 2023, 44(22): 201–209. DOI:10.13386/j.issn1002-0306.2023020137.

[3] Li Z., Bi J., Yi J., et al. Texture study of pectin-cellulose-small-sugar aerogels prepared by vacuum freeze drying. Journal of Nuclear Agriculture, 2022, 36(09): 1805–1814.

[4] Pharmacopoeia of the People’s Republic of China, 2020 edition, Part IV — General Rule 0981: Test for Crystallinity.

[5] Uguz S. S., Ozel B., Grunin L., Ozvural E. B., Oztop M. H. Non-Conventional Time Domain (TD)-NMR Approaches for Food Quality: The Case of Gelatin-Based Candies. Molecules, 2022, 27, 6745.

[6] Grunin L., Oztop M. H., Guner S., Baltaci S. F. Exploring the crystallinity of different powder sugars through solid echo and magic sandwich echo sequences. Magnetic Resonance in Chemistry, 2019; 57: 607–615.

[7] Pocan P., Grunin L., Oztop M. H. Effect of Different Syrup Types on Turkish Delights (Lokum): A TD-NMR Relaxometry Study. ACS Food Science & Technology, 2022, 2(12): 1819–1831.

Phone: 400-060-3233

After-sales: 400-060-3233

Back to Top