Biomass energy offers a sustainable route to reduce greenhouse gas emissions and lower dependence on fossil fuels. Traditional feedstocks such as corn and wheat compete with food supplies; large-scale planting of bioenergy crops in some Western countries also uses arable land and may have ecological impacts. In contrast, using agricultural and forestry residues—such as bagasse, corn cobs, straw and reeds—as feedstock for cellulosic ethanol is attractive because these lignocellulosic materials are abundant and continuously available, and conversion technologies are steadily improving. This approach has strong development potential.

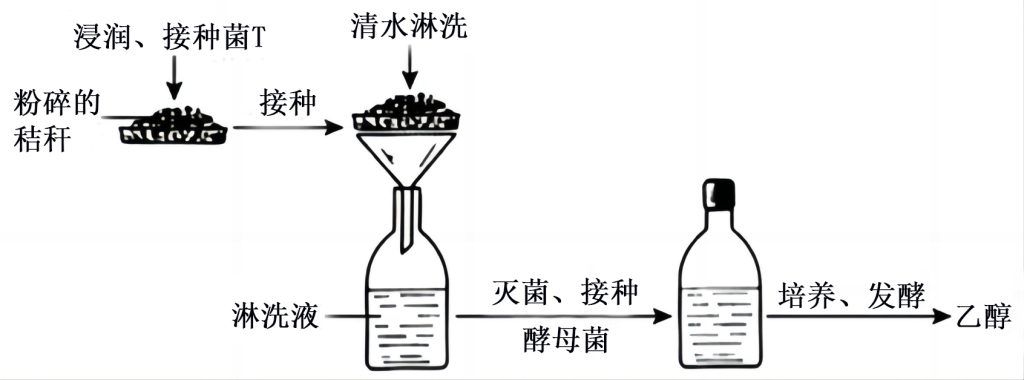

The conversion of biomass to ethanol consists of two main stages: hydrolyzing cellulose into fermentable sugars, followed by fermentation of those sugars to ethanol. A typical biochemical fermentation process is illustrated below[1].

Recently the State Council issued the “Action Plan to Promote Large-Scale Equipment Renewal and Trade-in of Consumer Goods” (the “Plan”), which encourages the development of bio-liquid fuels produced from waste oils and non-food biomass. For key processes such as enzymatic hydrolysis and fermentation, we recommend applying low-field NMR methods for process evaluation and optimization — LF-NMR can provide rapid, non-destructive molecular-level insight that helps improve yields and efficiency.

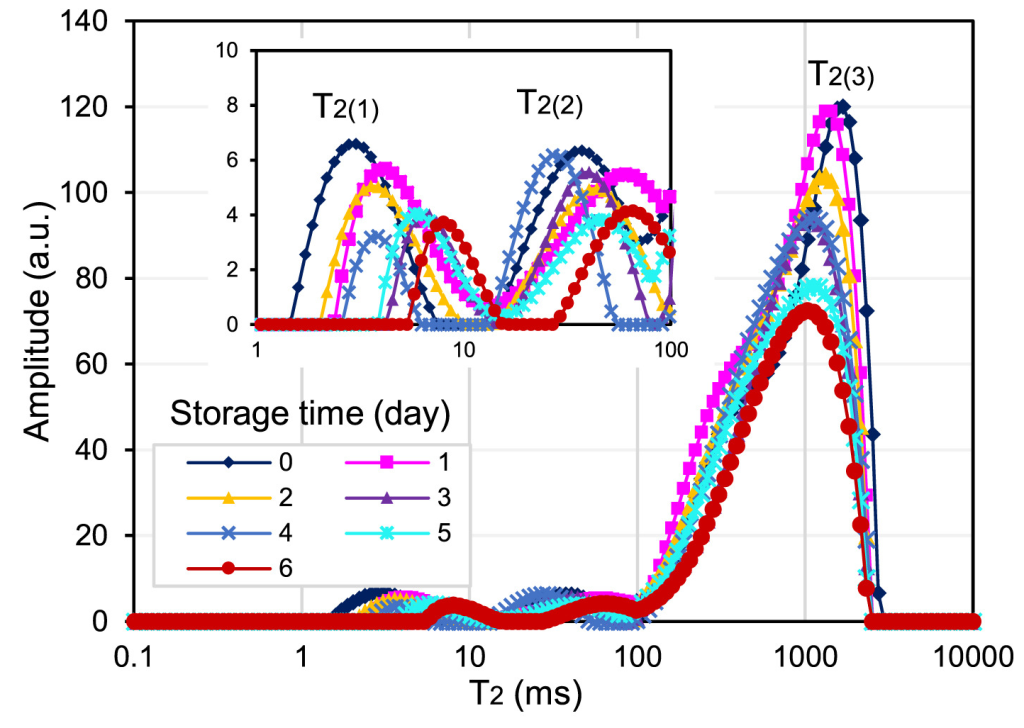

Saccharification converts lignocellulose into soluble sugars and requires pretreatment followed by enzymatic hydrolysis. Low-field NMR can monitor the T2 distribution before and after hydrolysis to reveal how water molecules are bound within the biomass (short-T2 tightly bound water, mid-T2 immobilized water, long-T2 free water). These measurements help assess hydrolysis effectiveness and enable multi-dimensional evaluation of feedstock types (herbaceous, softwood, hardwood), pretreatment methods (steam explosion, acid hydrolysis, etc.), and commercial enzyme formulations, supporting selection and optimization of processing routes. [2][3]

The figure below shows a typical plant water-distribution map used for such analyses.[4]

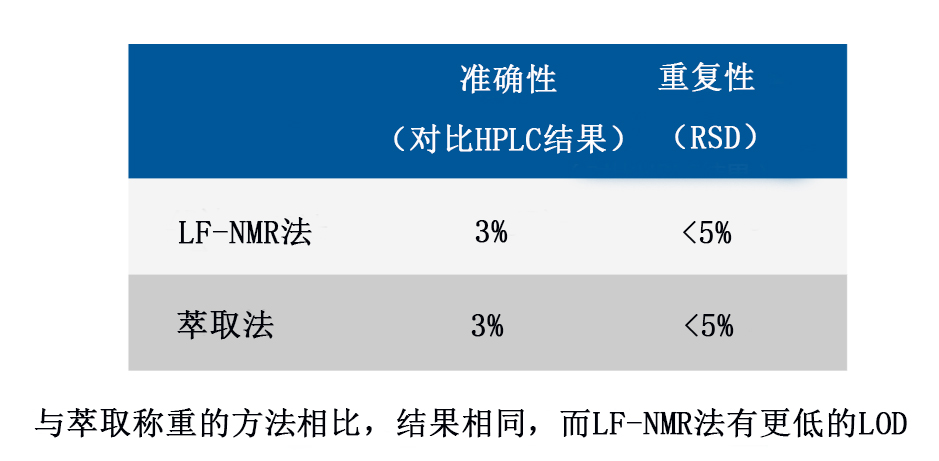

Pretreatment can release lipids from biomass into the fermentation broth; measuring oil content helps evaluate lipid recovery and design downstream extraction. Traditional oil assays rely on solvent extraction (time-consuming and solvent-intensive) or chromatographic methods (which require extensive sample prep); near-infrared methods sometimes lack quantitative sensitivity. Low-field NMR fills this gap by providing fast, solvent-free, quantitative measurements of oil concentration in fermentation broths, enabling continuous or frequent monitoring of the process and informing optimization decisions.[5][6]

As a green, non-destructive analytical tool, low-field NMR enables rapid, continuous assessment of biomass and fermentation streams and is well suited to evaluating processes in cellulosic ethanol production. LF-NMR’s versatility means it can also be extended to other synthetic-biology workflows and bioprocess monitoring tasks where fast, reagent-free molecular insight is valuable.

[1] Analysis of China’s fuel-ethanol industry development status, Huajing Intelligence Network, 2017-06-20.

[2] Zhang H., Gao F., Zhang L., et al. Determination of water states and analysis of bound-water mechanisms in fresh wet sweet-potato residues. Food Science, 2024: 1–11.

[3] Tatiane S. Bianquini, Camila Florencio, Rodrigo H. dos S. Garcia, Luiz A. Colnago, Sandra R. Ceccato-Antonini, Marcelo Carmo, João Teles, Cristiane S. Farinas, Tatiana S. Ribeiro. Time-domain NMR spectroscopy as a fast method for probing the efficiency of biomass pretreatments for second-generation ethanol production. Biomass & Bioenergy, 2020, 142: 105734.

[4] Wang H., Li X., Wang J., et al. Effects of postharvest ripening on water status and distribution, drying characteristics, volatile profiles, phytochemical contents, antioxidant capacity and microstructure of kiwifruit (Actinidia deliciosa). Food Control, 2022, 139: 109062.

[5] Maitra S., Long S., Singh V. Optimizing chemical-free pretreatment for maximizing oil/lipid recovery from transgenic bioenergy crops and its rapid analysis using time-domain NMR. Frontiers in Energy Research, 2022.

[6] Zhang Y., Wang Z., Chen Z., et al. A low-field NMR rapid quantitative method for measuring oil concentration in fermentation broths. Chinese Journal of Antibiotics, 2017, 42(08): 673–679.

Phone: 400-060-3233

After-sales: 400-060-3233

Back to Top