Hydraulic fracturing is a core technique in the development of unconventional oil and gas resources. Its success relies heavily on the formulation of high-performance fracturing fluids. Among various systems, **hydroxypropyl guar (HPG)-based water-based polymer fracturing fluids** have become a mainstream choice in shale gas operations due to their excellent viscosifying performance and environmental friendliness. Through crosslinking, HPG forms a **three-dimensional network structure** that gives the fluid unique rheological properties. This structure not only effectively suspends proppants, but also maintains stable performance under high-temperature and high-pressure downhole conditions.

As a key parameter that reflects the network structure of HPG fracturing fluids, **crosslinking degree** directly affects multiple performance metrics. Crosslinking density determines the system’s **elastic and viscous moduli**, thus influencing proppant carrying capacity and fracture propagation. A suitable crosslinking degree is also critical to ensure **thermal stability**, especially for deep, high-temperature reservoirs. Moreover, the structural features of the crosslinked network affect **gel breaking behaviour**, return flow efficiency, and reservoir protection.

Current techniques for evaluating fracturing fluid crosslinking degree still face major challenges. Researchers often need to combine multiple testing methods to comprehensively assess crosslinking status. At present, evaluations mainly rely on **rheometers** (to measure viscoelasticity) and **infrared spectroscopy** (to monitor functional group changes). However, **rheometers only capture macroscopic mechanical behaviour** and cannot distinguish microscopic structural differences in the network, while **IR analysis suffers from complex sample preparation and poor quantification precision**. Neither method offers direct quantification. Therefore, a more efficient and accurate analytical tool is urgently needed. Low-field nuclear magnetic resonance (LF-NMR), owing to its sensitivity to molecular motion, has recently demonstrated unique advantages in characterizing polymer crosslinked networks. It provides fast, quantitative measurement of crosslinking degree, and has emerged as a promising solution for HPG fracturing fluid characterization.

Samples: Hydroxypropyl guar (HPG); heavy water; crosslinkers including ethylene glycol, boric acid, D-sorbitol, and cyclic borate crosslinker (OBC).

Instrument: Low-Field NMR Analyzer (MicroMR12-040V)

1. Preparation of Fracturing Fluid Gel:

HPG powder was dissolved in heavy water and allowed to rest at room temperature (20 °C), followed by water bath swelling at 25 °C for 4 hours to obtain the base fluid.

Various concentrations (0.1% to 1.0%) of OBC crosslinker were added into separate base fluids and stirred evenly to obtain gels with different degrees of crosslinking.

2. LF-NMR Testing:

Low-field NMR measurements were performed using the MicroMR analyzer with a CPMG sequence to acquire the proton T2 relaxation time distributions.

Test parameters: sampling bandwidth (SW) = 200 KHz, wait time (TW) = 1500 ms, RFD = 0.02 ms, receiver gain (RG) = 10 dB, digital gain (DRG) = 3, preamplifier gain (PRG) = 3, number of scans (NS) = 8, echo time (TE) = 0.15 ms, number of echoes (NECH) = 2000.

The T2 relaxation spectra were analysed to quantify the crosslinking degree.

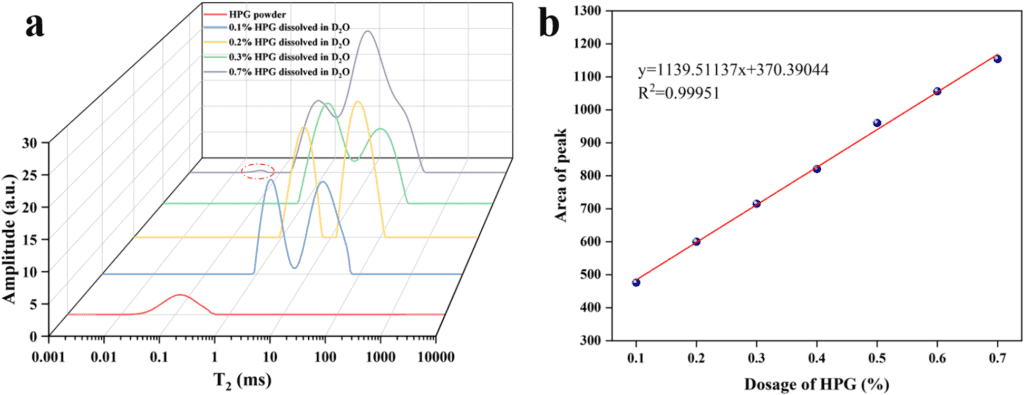

Figure 1: HPG base fluids at 0.1–0.7% concentrations: (a) relaxation distribution; (b) relationship between total T2 area and guar content

Figure 1 shows the relaxation distributions of guar gum powders and base fluids prepared with heavy water at different concentrations, along with changes in peak area. As shown in Figure 1(a), the dry guar powder exhibits only a fast relaxation peak (0.03–1 ms), likely due to its rigid, non-hydrated state without mobile linear chains. In contrast, HPG base fluids prepared with 0.1–0.7 wt% show two distinct peaks. As concentration increases, both the area and position of these peaks shift. At 0.7 wt%, a peak appears around 0.05 ms, aligning with the solid powder signal, possibly due to undissolved HPG molecules at high concentration.

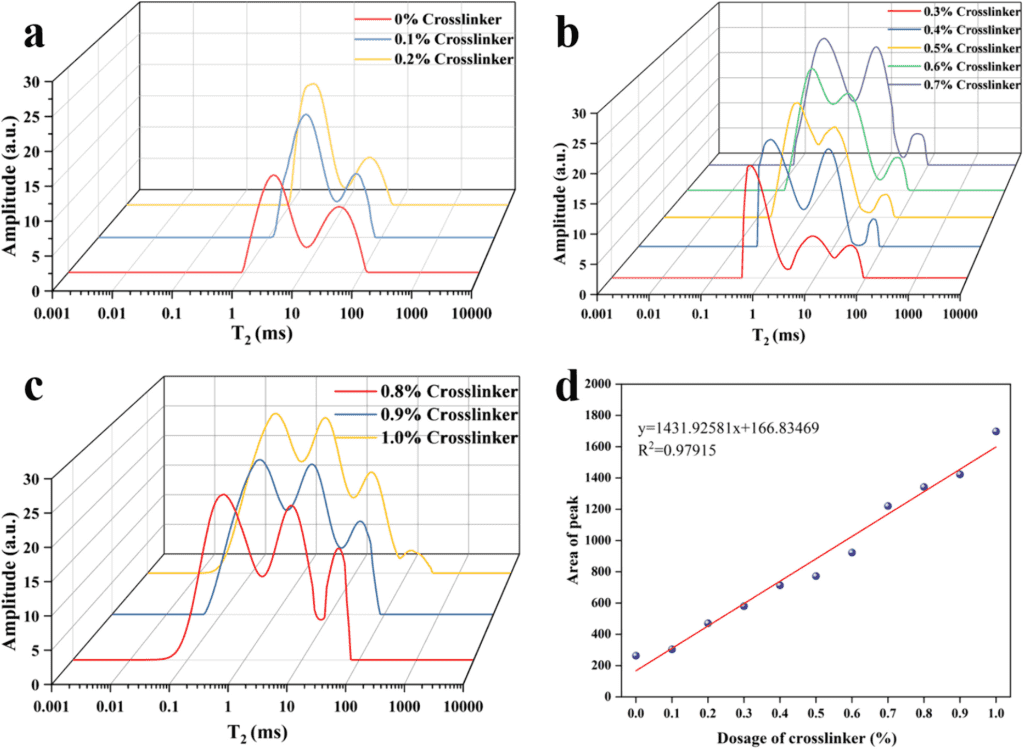

Figure 2: Relaxation distributions under different OBC crosslinker dosages: (a) 0–0.2%

As shown in Figure 2, multiple peaks emerge in the relaxation spectrum as the crosslinker dosage increases. The signal strength and proportion of fast-relaxing components rise significantly, indicating reduced molecular mobility—attributable to denser gel networks formed by crosslinking. In Figure 2(c), increasing crosslinker concentrations to 0.8%, 0.9%, and 1.0% broadens the T21 peak to 0.04–3 ms, while T22 and T23 positions remain stable. This reflects a tighter gel network, likely from over-crosslinking. The T2 distribution captured by LF-NMR reflects the motion behaviour of both linear and film-like structures formed by HPG–crosslinker interactions. At 1.0% crosslinker, a late peak (100–300 ms) indicates unreacted excess crosslinker, confirming the presence of free molecules not bound in the gel.

These results confirm that LF-NMR relaxation analysis enables quantitative evaluation of the crosslinking degree in fracturing gel systems, providing valuable insight for formulation optimisation and real-time monitoring.

If you are interested in the above application, feel free to contact us: 18516712219

[1] Zhang C, Wang Y, Yin Z, et al. Quantitative characterization of the crosslinking degree of hydroxypropyl guar gum fracturing fluid by low-field NMR. International Journal of Biological Macromolecules, 2024, 277(Part 3): 11. DOI: 10.1016/j.ijbiomac.2024.134445.

Phone: 400-060-3233

After-sales: 400-060-3233

Back to Top