Understanding the microstructural changes of natural rubber polymers under tensile deformation is essential for evaluating the mechanical performance of rubber materials. However, no technique currently allows for in-situ monitoring of polymer behavior under stretching. This application introduces an innovative low-field nuclear magnetic resonance (LF-NMR) system equipped with a custom tensile module (Figure 1), enabling direct, real-time molecular dynamics analysis during deformation. This approach offers deep insight into how polymer structures and dynamics evolve under realistic working conditions.

Figure 1: Structure of the in-situ tensile testing + LF-NMR system

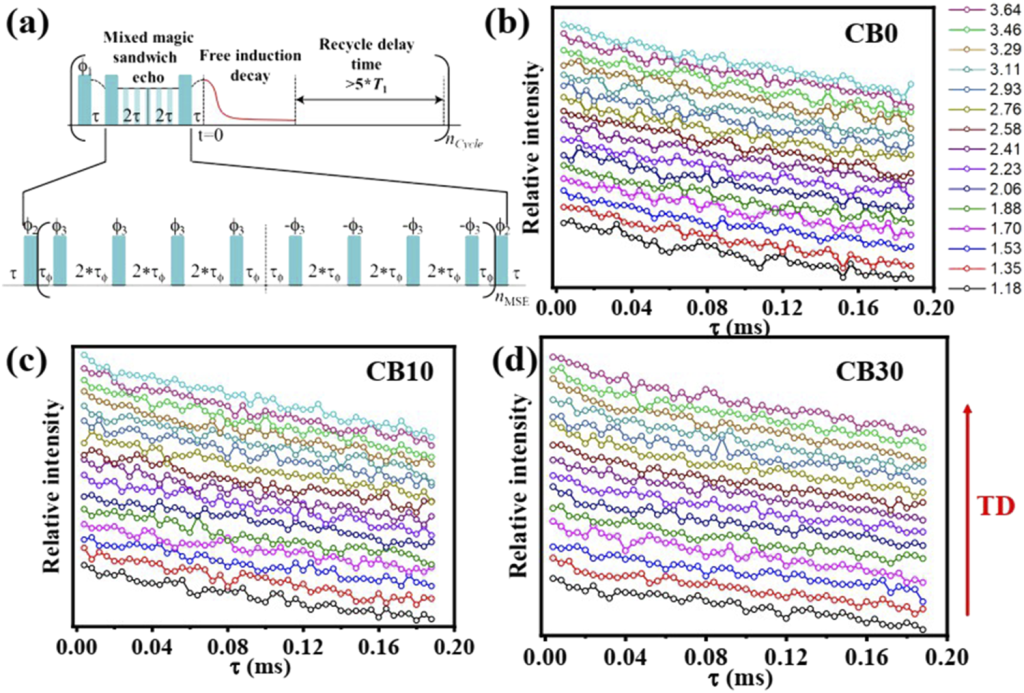

This setup was used to test natural rubber films. The experiments applied an MSE sequence (Figure 2a), which differs from the FID sequence in that it refocuses signals lost during dead time, ensuring complete NMR relaxation capture. Figures 2(b)–2(d) show real-time relaxation data for natural rubber containing 0 phr (NRCB0), 10 phr (NRCB10), and 30 phr (NRCB30) of filler under various tensile stresses. Tests were conducted at ~35°C, the ambient temperature inside the LF-NMR sample chamber. Red arrows indicate increasing strain. Compared with filled samples, the NMR signal of unfilled natural rubber (NRCB0) remained nearly unchanged, indicating minimal dynamic response to deformation. In contrast, NRCB30 exhibited a pronounced change in slope post-stretching, indicating significant dynamic slowdown.

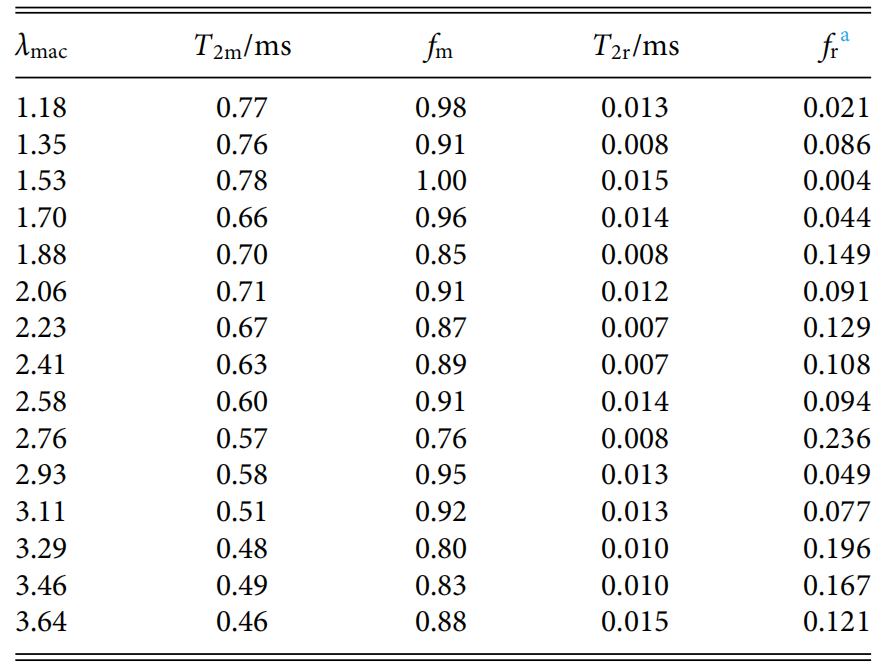

These results clearly demonstrate that rubber matrices respond more sensitively to strain as filler content increases. Carbon black restricts molecular motion, leading to greater molecular chain confinement. This behavior is attributed to the well-known “Mullins effect”—a strain amplification phenomenon caused by fillers. To quantify these molecular mobility changes, MSE data for NRCB30 were fitted to extract the transverse relaxation time (T2m) and fraction (fm) of mobile chains, as well as the relaxation time (T2r) and fraction (fr) of rigid chains. As NMR detects all hydrogen protons in the material, it provides continuous access to network dynamics throughout deformation.

Figure 2: (a) Principle of the MSE sequence; (b)–(d) NMR relaxation signals for natural rubber with different filler content under varying stress: (b) NRCB0, (c) NRCB10, and (d) NRCB30.

Table 1: Relaxation times and proportions of mobile and rigid chains in NRCB30

At the initial stage of stretching, T2m remains stable or slightly increases before showing a near-linear decline. This drop indicates increasing restriction in chain dynamics. For the rigid phase, the early-stage signal reflects tightly bound rubber associated with filler surfaces. As deformation continues, stress-induced crystallization (SIC) occurs, introducing additional rigid components. Thus, in the high-strain region, rigidity originates from both bound rubber and newly formed crystalline structures.

During deformation, bound rubber may detach, which could reduce rigidity. However, simultaneous crystallization counteracts this by adding new rigid segments. As a result, the relaxation time and fraction of rigid chains show no consistent trend, as also confirmed by the experimental data.

This application presents a breakthrough by integrating LF-NMR with tensile testing—enabling real-time, in-situ analysis of interfacial structure and dynamic changes under mechanical stress. It solves a long-standing challenge of tracking the microscopic state of materials during deformation.

If you’re interested in this application, feel free to contact us: 15618820062

Zhijie Xia, Yusong Wang, Ke Gong, Wei Chen; An in situ stretching instrument combined with low field nuclear magnetic resonance (NMR): Rheo-Spin NMR. Rev. Sci. Instrum. 1 March 2022; 93 (3): 033905.

Phone: 400-060-3233

After-sales: 400-060-3233

Back to Top