Ding Dong~

The second edition of the “Newmai Cup” Jiangnan University Outstanding Case Analysis is here!

We sincerely thank our research partners and industry colleagues for their continued attention. Today, we are excited to share another remarkable study from the competition—“Investigation of Moisture Distribution Changes in Frozen Rice During Different Storage Periods”.

The frozen rice industry, as a vital segment of modern food manufacturing, has grown in response to rising consumer demand for convenient, safe, nutritious meals that closely mimic freshly cooked rice. Freezing technology maximises inhibition of microbial growth and biochemical reactions, ensuring food safety and extending shelf life. This aligns perfectly with the fast-paced lifestyle of modern consumers who seek convenient yet healthy staple foods. Industry trends are increasingly geared toward higher-quality products, requiring frozen rice to maintain water retention, texture (such as firmness and viscoelasticity), and taste even after long-term storage.

However, the industry faces critical challenges stemming from quality deterioration during freezing, storage, and thawing. Water migration and recrystallisation are key factors. Ice crystal formation inside rice during storage leads to uneven moisture distribution and increased free water content, reducing water-holding capacity, hardening rice grains, producing rough textures (e.g., changes in stickiness and hardness ratio), and degrading overall structure, which negatively affects consumer acceptance. Addressing moisture state and texture stability during frozen storage is essential to improving frozen rice quality and advancing the industry.

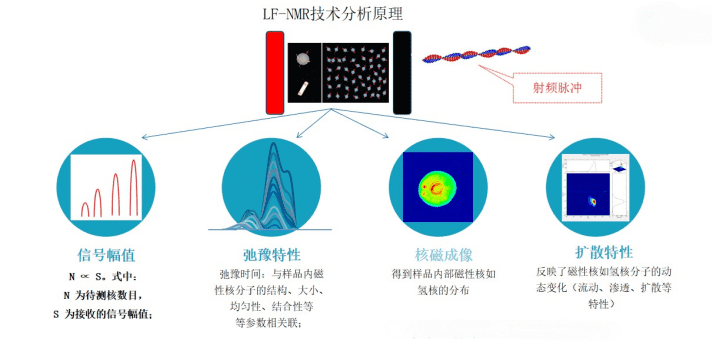

The study explored how different rice processing methods (retaining endosperm vs. fully polished) affect moisture status during frozen storage, and how this relates to texture stability. Low-field nuclear magnetic resonance (LF-NMR) and magnetic resonance imaging (MRI) techniques were employed to non-invasively analyse water molecules within rice samples (including bound water, less mobile water, and free water) and their dynamic changes during storage.

Figure 1: LF-NMR Analysis Principle

The study compared three representative rice types/treatments: fully polished Nanjing 9108 rice (NJ9108), Akita Komachi rice (QTXT), and Nanjing 9108 rice with retained endosperm (PYM).

1. Sample Preparation: Cooked rice was frozen and sampled at predetermined storage intervals (0, 14, 30, 60 days).

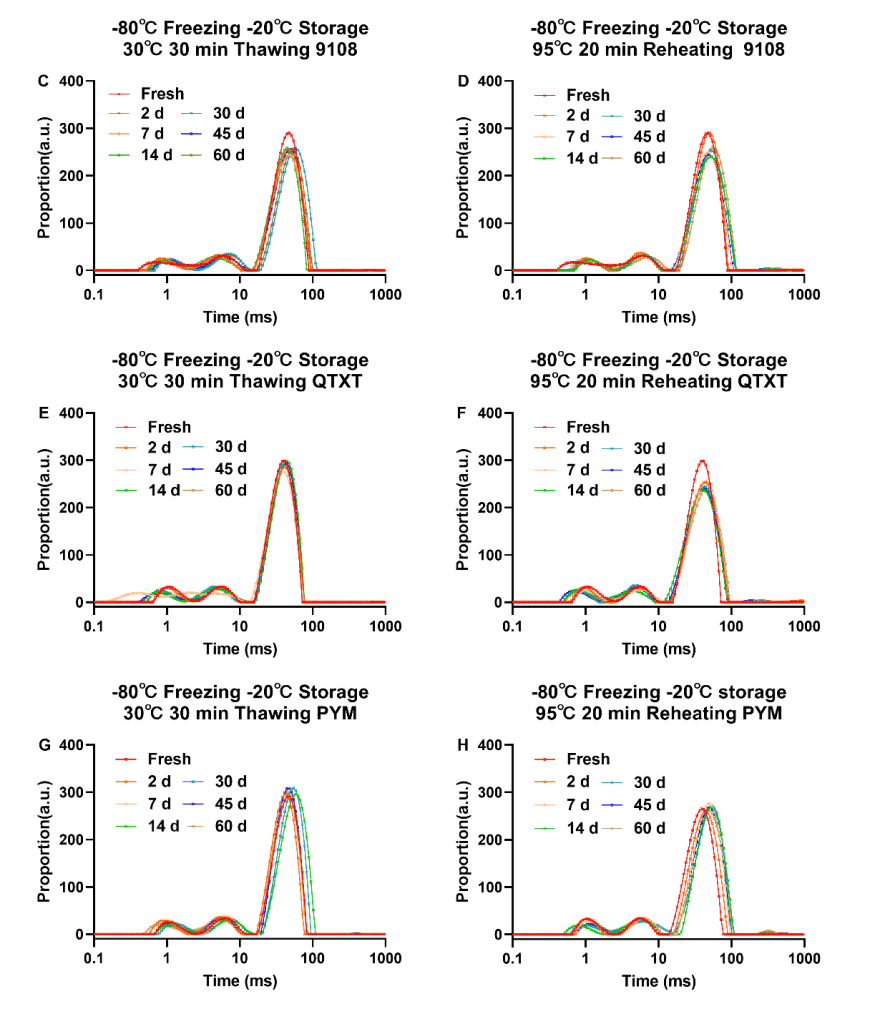

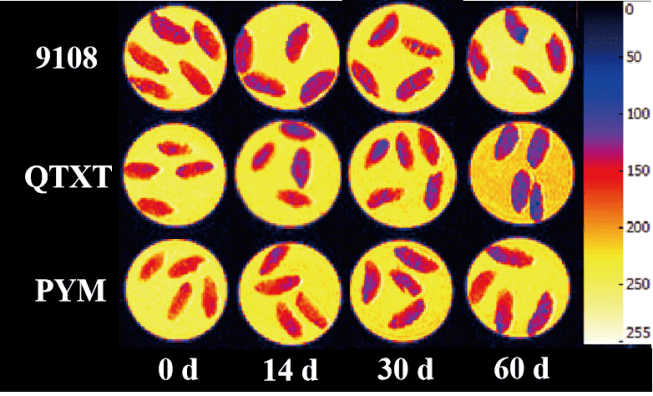

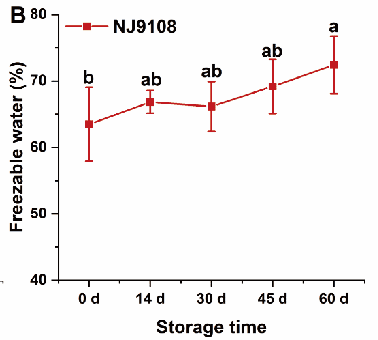

2. Moisture State Analysis: LF-NMR measured the water relaxation characteristics at each storage point to calculate proportions of different water types, particularly the change in free water content (T22). MRI was used to visualise the uniformity of water distribution.

Figure 2: T2 Relaxation Time Distribution Spectrum of Frozen Rice

Figure 3: Moisture Distribution MRI

3. Comparison Focus: Differences in moisture status (particularly free water content and uniformity) during long-term frozen storage.

Experimental Results:

1. Frozen rice showed reduced water binding and increased water mobility.

2. Rice with retained germ maintained relatively stable water binding, with a slight increase in mobility.

3. Differences in water binding caused by ice recrystallisation persisted after reheating.

4. Long-term stored rice exhibited uneven internal moisture distribution.

5. In conventional white rice, limited hydrated regions expanded as transverse cracks.

6. Rice samples with retained germ retained moisture distribution closer to freshly cooked rice.

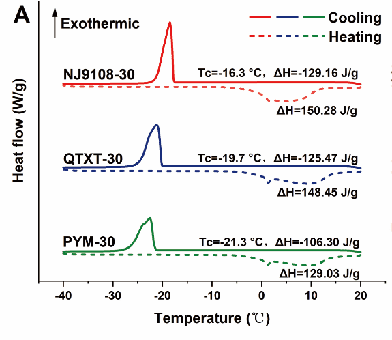

Figure 4: Freeze-Thaw Curves and Freezable Water Content Changes

Phone: 400-060-3233

After-sales: 400-060-3233

Back to Top