In the fast-paced and competitive textile and chemical fiber industry, spin finish (oil applied to fibers) is a make-or-break factor. It directly influences processing smoothness, fiber durability, and the final quality of fabrics—making accurate and efficient spin finish measurement critical for consistent production. For decades, manufacturers relied on outdated methods like solvent extraction, but these approaches are slow, destructive, and environmentally harmful. Today, low-field NMR (LF-NMR) technology is revolutionizing spin finish testing, offering unmatched precision, speed, and sustainability that aligns with modern manufacturing demands.

Why Spin Finish Measurement Matters—And the Limitations of Traditional Methods

Spin finish is far more than a “surface detail” in fiber production. It reduces friction during spinning, weaving, and knitting, prevents fiber breakage, and ensures uniform fabric texture. However, measuring spin finish accurately has long been a challenge. Traditional solvent extraction methods require harsh chemicals, destroy valuable samples, and take hours to deliver results. Worse, they generate toxic waste, driving up environmental costs and conflicting with global sustainability goals. For bio-based fibers—one of the fastest-growing segments in the industry—these destructive methods are even less viable, as they contradict the principles of green manufacturing.

Manufacturers need a solution that delivers real-time, reliable spin finish data without compromising speed, sample integrity, or the planet. That’s where low-field NMR comes in.

Low-Field NMR: How It Transforms Spin Finish Measurement

Low-field NMR operates in the time-domain, focusing on the relaxation behavior of hydrogen nuclei—a key component of both spin finish (oil) and fiber molecules. Here’s how it works:

Figure 1: Characterization of Oil and Fiber Signals in NMR Methods

This physics-based method eliminates human error (a flaw in operator-dependent traditional techniques) and delivers consistent, repeatable results every time.

For textile manufacturers, low-field NMR checks all the boxes for effective spin finish measurement:

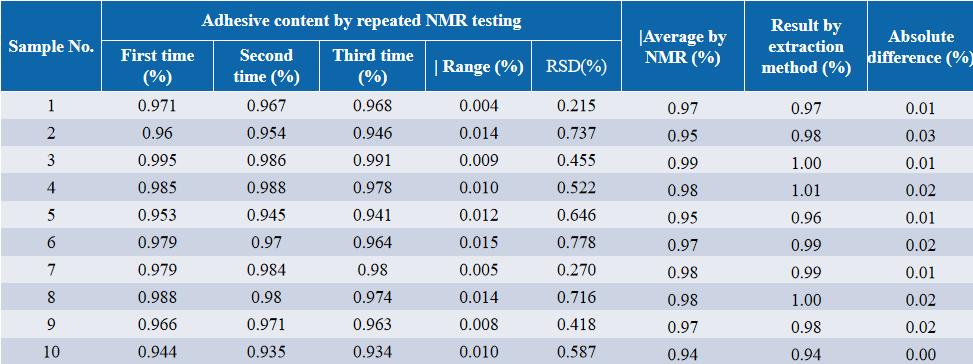

A side-by-side comparison of low-field NMR and traditional solvent extraction (see Figure 2) confirms LF-NMR’s superiority:

Figure 2: Comparison of the accuracy of NMR methods and traditional extraction methods

From Lab to Production: Low-Field NMR’s Real-World Impact on Spin Finish Control

Leading textile and chemical fiber manufacturers are already leveraging low-field NMR to optimize spin finish application:

Whether you’re producing conventional fibers or next-gen bio-based materials, low-field NMR integrates seamlessly into your quality control workflow—turning spin finish measurement from a bottleneck into a competitive advantage.

Embrace the Future of Spin Finish Measurement with Low-Field NMR

The shift to low-field NMR isn’t just an upgrade — it’s a strategic move to align with precision manufacturing and sustainability trends. By replacing slow, wasteful, and destructive methods with fast, clean, and accurate LF-NMR technology, you’re not just measuring spin finish—you’re ensuring operational efficiency, reducing costs, and delivering exceptional products that stand out in the market.

Ready to transform your spin finish quality control? Explore industry-leading low-field NMR solutions tailored for textile and fiber manufacturers. Visit our dedicated application page for case studies, technical specs, and application notes: Textile-Industry-Niumag

Figure 3: LF-NMR Analyzer: PQ001-Fiber-Pro

With low-field NMR, precision spin finish measurement is no longer a challenge—it’s your key to success in the modern textile industry.

Phone: 400-060-3233

After-sales: 400-060-3233

Back to Top