During the production of sulfur, a certain amount of oil is often added based on product quality and performance requirements. This improves product characteristics and facilitates processing and handling. To ensure consistent product quality, accurate and rapid measurement of oil content in sulfur is essential. Low-field NMR technology enables fast and simple oil content testing with minimal sample preparation, making it ideal for real-time quality inspection and control in industrial production lines.

The traditional approach for measuring oil content in sulfur involves solvent extraction. However, this method is complex, time-consuming, and requires skilled operators. It is also prone to human error. Additionally, the solvents used are toxic, posing health and safety risks to personnel. As a result, this method is increasingly unsuitable for industrial applications.

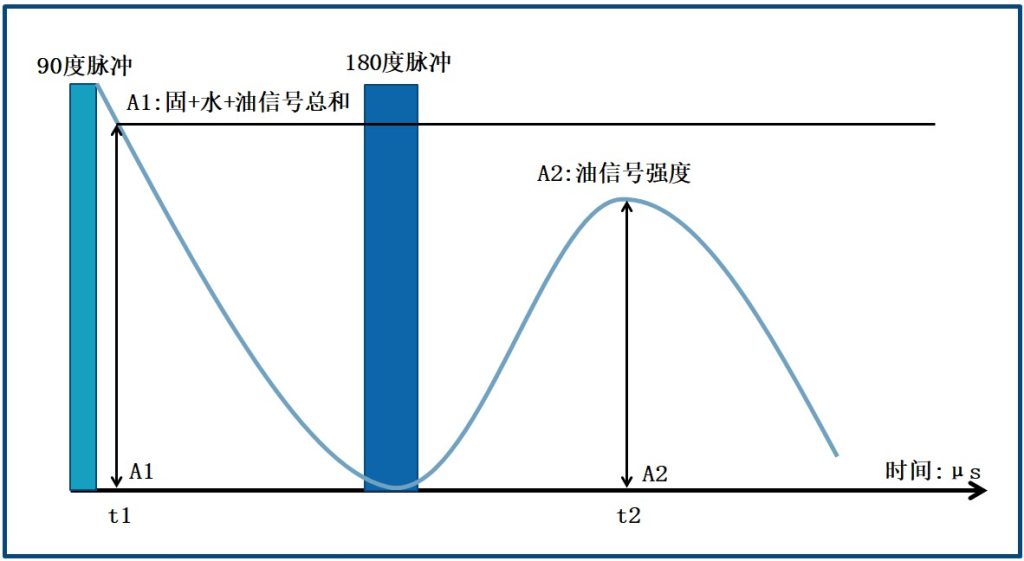

Low-field NMR uses a spin-echo sequence for measurement. As shown in the diagram, the NMR signal is captured following a 90° RF pulse. At point t1, the Free Induction Decay (FID) signal is recorded, and its amplitude (A1) is proportional to the hydrogen protons present in both water and oil phases of the sample. After a 180° pulse, the spin-echo signal amplitude (A2) is captured. At this point, the water signal has fully decayed, and A2 reflects only the oil signal.

Once the system is calibrated using samples with known oil content, the oil content in unknown samples can be determined quickly. The LF-NMR testing process is fast and non-destructive, typically taking just 30 seconds to 3 minutes. It is highly suitable for online and real-time monitoring in industrial environments.

Phone: 400-060-3233

After-sales: 400-060-3233

Back to Top