With the rapid development of industrialisation and urbanisation in China, the discharge of solid waste is increasing. Effectively managing and treating this waste has become a critical issue.

Most cities in China currently handle solid waste primarily through landfill and incineration, which is increasingly causing environmental issues. For instance, landfills consume large areas of land, while incineration can release toxic gases and fly ash. In response, the government is promoting waste reduction, classification, and recycling, aiming to improve recovery rates and minimise emissions[1].

Low-field Nuclear Magnetic Resonance (LF-NMR), widely used in geotechnical and energy material analysis, is a mature method for analysing structure characterisation, water content and distribution, dynamic migration, in-situ damage, and fracture orientation.

Solid waste treatment and the development of a circular economy impose higher requirements on new materials, especially in areas like cement production from tailings, waste solidification, coal gangue fragmentation, soil amendment using gangue, and sludge stabilization.

LF-NMR enables fast, non-destructive testing of macro samples and microscopic structural characterisation, providing strong analytical support for solid waste applications[2].

Using LF-NMR to monitor solidification and hydration behaviour of samples, the following conclusions were drawn[3]:

1. After adding cement into sludge, a large amount of pore water is rapidly transformed into chemically bound water within 7 days, forming a pore-structured skeleton. After 7 days, the hydration process slows, and the solidified 3D matrix stabilises with only minor changes in pore structure.

2. The water conversion mechanism reveals that a lower cement dosage results in a more complete hydration reaction.

3. Based on the hydration model, once the NMR parameter Mhw is obtained, permeability, strength, and deformation characteristics can be estimated, providing valuable guidance for engineering applications.

Coal gangue contains a certain amount of hydrogen, which contributes to improved mechanical strength in building materials. The hydrogen content directly affects the final mechanical performance.

Raw coal gangue sample

Coal gangue bricks

Multiple coal gangue samples were tested using a NUMAI LF-NMR analyser to measure hydrogen content. By normalising the hydrogen signal and applying a calibration curve, the hydrogen content of each sample was calculated as shown below:

Based on these results, high-hydrogen-content coal gangue can be quickly selected and used for producing high-strength construction materials.

This case combines mechanical loading with LF-NMR imaging to study the triaxial stress–strain behaviour of coal samples. Using the pseudo-triaxial NMR device developed by NUMAI, both mechanical response and internal fluid distribution can be observed in-situ during compression testing[4].

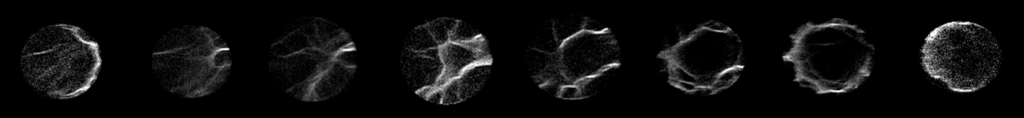

Stress–strain response and NMR imaging of three coal samples

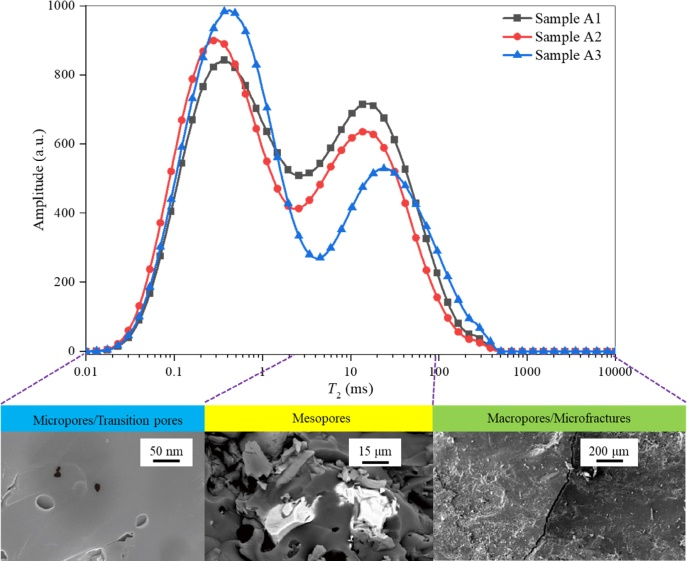

T2 spectrum and pore size classification of coal samples under hydrostatic pressure

With combined mechanical and NMR testing, the following conclusions are drawn:

In Fig. 1, the peak strengths of the three coal samples are 49.5 MPa, 47.2 MPa, and 45 MPa, with maximum strains of 3.59%, 3.7%, and 3.47% respectively. The NMR imaging visualises the internal water distribution during loading—warmer colours indicate higher water content.

Fig. 2 presents the T2 spectrum under hydrostatic loading. Based on T2 relaxation times: short T2 (<2.5 ms) indicates micropores and transition pores, medium T2 (2.5–100 ms) refers to mesopores, and long T2 (>100 ms) represents macropores and microcracks.

By coupling mechanical loading with LF-NMR, the evolution of PFS (pore–fracture systems) content and spatial distribution can be tracked in real-time, and a pore compressibility model can be established to accurately describe stress sensitivity of storage space.

Rock samples were subjected to stress–damage analysis using the pseudo-triaxial low-field NMR equipment provided by NUMAI. Below are the axial pressure loading graph and porosity variation curves[5].

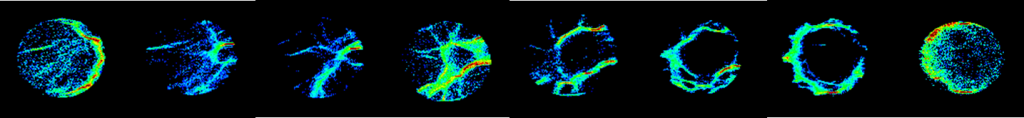

NMR imaging comparison chart

As axial pressure increases, the number of internal cracks grows, leading to progressive damage.

When axial stress is below 90% of the triaxial compressive strength, damage in marble is primarily driven by an increase in small internal pores.

Once axial stress exceeds 90% of the compressive strength, damage accelerates dramatically, ultimately causing failure. This is due to a rapid increase in both the number and width of internal fractures.

[1] Jiang Ling, Sun Jingnan, Liu Gang. Enhancing Solid Waste Treatment Capacity and Promoting Resource Utilisation – An Environmental Policy Analysis for the Renewable Resource Industry [J]. Environmental Protection, 2017(20):10–15.

[2] Haijun HE, Xi M, Jian T, et al. Event-triggered-based self-organising fuzzy neural network control for the municipal solid waste incineration process [J]. Chinese Science: Technological Sciences (English Edition), 2023.

[3] Wang Shiquan, Wei Mingli, He Xingxing. Study on Water Transformation Mechanism during Sludge Solidification Based on NMR Technology [J]. Rock and Soil Mechanics, 2019(5):1778–1786.

[4] Hongwei Zhou, Zelin Liu, et al. In-situ observation and modelling approach to evolution of pore-fracture structure in coal [J]. International Journal of Mining Science and Technology, 2023.

[5] Zhou Keping, Hu Zhenxiang, Gao Feng. Study on Triaxial Compression Damage of Marble Based on Low-field NMR Technology [J]. Rock and Soil Mechanics, 2014, 35(11):3117–3122.

Phone: 400-060-3233

After-sales: 400-060-3233

Back to Top