Time Domain NMR Study of Oil Crystallization Behavior

Overview of Oil Crystallization Behavior

In the field of food industry, the formation of oil crystal network consists of two stages. One stage is rapid cooling and kneading on the production line to rapidly crystallize the oil, resulting in small and stable crystals, and then through the aging process to obtain a crystalline product with stable structure; One stage is the change stage of the crystallization behavior of the stable oil and fat crystalline products formed by curing during storage and transportation, and the latter stage is actually the stage when the oil and fat products come out of the manufacturing plant until they are used by the end user.

The general dynamic process of oil crystallization can be described as: the degree of supercooling drives the orderly arrangement of triglyceride molecules to form a molecular thin-layer structure; the thin-layer structure is further superimposed to form nano-scale crystallites; each crystallite unit aggregates and grows into crystal clusters Finally, the crystal clusters continue to agglomerate, interweave, and fill to form a three-dimensional crystalline network structure, which is a macroscopically visible solid fat. The three-dimensional network structure of fat crystallization is very similar to the colloidal structure in which flocculation occurs. The change of crystallization conditions during the crystallization process of oil has a great influence on the formation and macroscopic properties of its three-dimensional network structure, which is related to the final quality of the product.

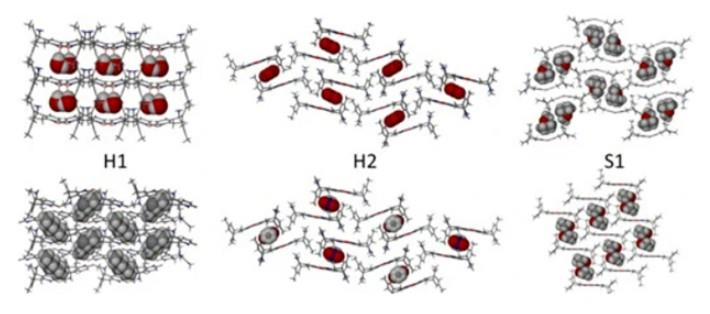

Homogeneous polymorphism of oils and fats

Polymorphism refers to the existence of more than one crystalline form of the same substance. The triglyceride molecule is composed of one glycerol and three fatty acids. After the oil is crystallized, the methylene groups on the hydrocarbon chain of the fatty acid molecule are arranged in a zigzag pattern, while the entire triglyceride molecule is mostly arranged in bimolecular or trimolecular units. The differences in the arrangement of triglycerides and the hydrocarbon groups of fatty acids during aggregation and entrapment will inevitably lead to differences in subunit cell structures, and ultimately lead to different forms of crystals formed, that is, Hom polymorphism occurs.

Studies have shown that there are three main types of homogeneous polymorphism in oils, namely α-type, β’-type and β-type. For the same triglyceride, the melting points of the three crystal forms increased sequentially, the stability increased sequentially, and the melting enthalpy also increased sequentially. The crystals obtained by quenching the molten oil are usually α-type, which usually exists for a short time in the initial stage of oil processing, and then slowly transform into β′ and β-type crystals. The solid fat is slowly heated to melt it, and it crystallizes at a temperature slightly higher than its melting point, mostly forming the β’ crystal form. The β’ crystal form has small crystals, fine grains, good plasticity, spreadability and taste, and is an ideal crystal form for shortening, margarine, spread fat and other products. Slowly heating the β’ crystal form to melt it, and keeping it at a temperature slightly higher than its melting point, or recrystallizing it from a solvent at a low temperature, can obtain the β crystal form, and the particles of the β crystal form are relatively coarse. At the same time, the different crystal forms of the crystal can be transformed into each other. Generally speaking, the crystal will change in the direction of increasing stability, that is, α-type→β′-type→β-type. In the production and storage stage of the actual product, the transformation of the fat crystal form is affected by various factors such as temperature and time.

The polymorphism of oils and fats affects their crystallization behavior (including crystallization rate, crystal size, morphology, and total crystal mass), which in turn affects the physical properties of these oils and fats. The study of fat crystallization has great scientific and practical significance. By measuring the behavior of fat crystallization, the production process can be guided, so that the final product can obtain the desired taste and texture. Each lipid exhibits different crystallization behaviors, promoting different three-dimensional arrangements in its fat crystal network in terms of the degree of order and polymorphic state of the fat crystals. The crystal structure and crystallization phenomena are greatly affected by many factors, such as cooling rate, fatty acid chain length and composition, TAG organization and some processing conditions, such as stirring speed. Variations in cooling rates may also affect microstructural features by controlling the nucleation and growth rates of crystals.

Time-domain NMR study of oil crystallization behavior:

Time-domain NMR relaxation measurement is a rapid, non-destructive detection method that can be used to evaluate physical and chemical changes in food systems. Time-domain nuclear magnetic resonance (TD-NMR) is usually based on the measurement of relaxation times of different pulse sequences, including so-called longitudinal relaxation times (T1) and transverse relaxation times (T2), which are related to physicochemical changes in the food system. Although the restricted molecular dynamics of solid fats limit the use of time-domain NMR to detect fat polymorphisms, it can still be used to study fat polymorphisms and crystal size distributions by combining relaxation time measurements with different experimental methods.

Time-domain NMR can study oil crystallization behavior from the following four aspects:

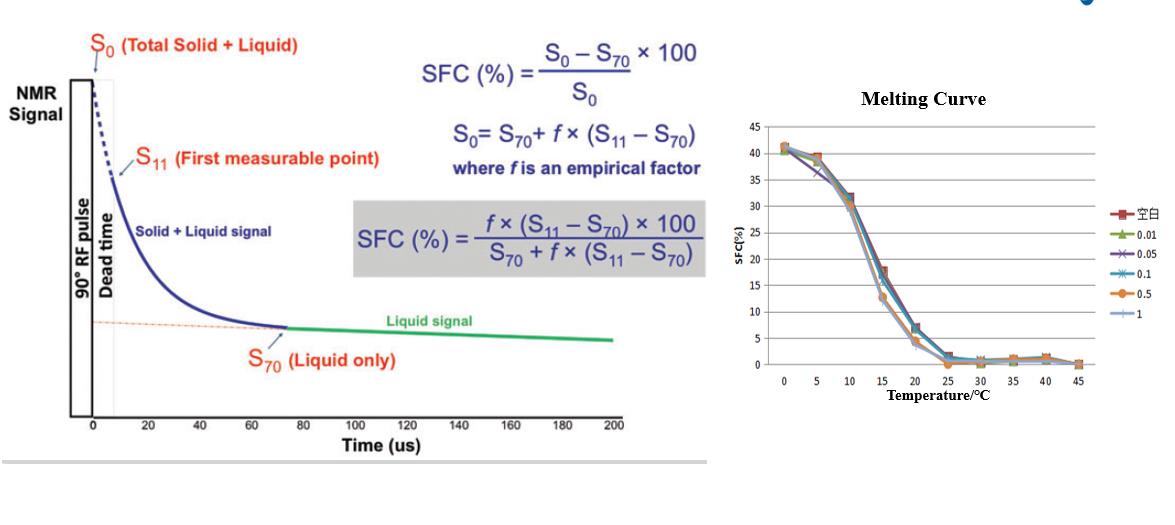

Measurements of solid fat content (SFC), spin-lattice relaxation time T1, spin-spin relaxation time T2 and second-order moment M2 parameters provide oil crystallization and molecular motion information. Time-domain NMR relaxation assays can be used to examine the crystallization behavior of oils and fats, which can provide valuable information about the molecular changes throughout the sample volume caused by crystallization in a fast and simple manner without the need for detailed spectral peak analysis. Compared with XRD, time-domain NMR relaxation can also provide more information about molecular dynamics and molecular conformational degrees of freedom, thereby providing precise atomic details. In this way, time-domain NMR relaxation measurements complement the XRD experiments by revealing more information about the molecular dynamics changes taking place in the samples, especially in the liquid state. This also helps to determine the overall crystallization behavior of lipid-containing samples. However, interpretation of time-domain NMR parameters still depends on comparison with results from reliable techniques such as XRD.

Solid Fat Content (SFC)

The number of fat crystals affects the macroscopic properties of the fat crystal network and is determined by the solid fat content (SFC). The relationship between solid fat content and temperature determines the specific application of edible oil/fat, and the solid fat content at different temperatures determines the use range and application field of the product. Therefore, SFC is a very important quality control parameter. SFC is a measure of the solid-to-liquid ratio of fat samples, and it also affects the crystalline properties of fat in terms of crystal polymorphisms.

Time Domain NMR Technology

In the food industry, control of fat crystallization is an important factor in ensuring the physicochemical properties of fat-based products. Time-domain nuclear magnetic resonance is a non-destructive testing technique that can be used to detect physicochemical changes in food. The time-domain NMR relaxation method can be used as a tool to explain the crystallization behavior of oil, which is complementary to the X-ray scattering technique.

NIUMAG Time domain NMR Solid Fat content analyzer

NIUMAG

NIUMAG