Low-field NMR Method for the Detection of Oil Content in Wool Fibers

Why Measure Oil Content of wool fibers?

Oil on the fiber is usually used as a lubricant or an antistatic agent, it is also used as a carrier for chemical agents such as fiber bactericides, flame retardants, and colorants. The oil content is also an important quality control parameter, which directly decide if the fiber can meet the requirements of its use. However, the uneven oil content is a high incidence problem in the chemical fiber production process. Fibers with low oil content are prone to static electricity, while fibers with high oil content are prone to entanglement, both of which will seriously affect the normal process of textile processing. Therefore, it is very important to accurately measure the oil content of fibers to accurately grasp and control the oil content.

Test Methods for the Oil Content of Wool Fibers

The test methods specified in the current standard GB/T 6504-2008 “Test Method for Oil Content of Chemical Fibers” include extraction method (hereinafter referred to as standard extraction method), neutral soap washing method, optical refractive index method and nuclear magnetic resonance method. In addition, in order to facilitate production, Sinopec has developed several new test methods, including “rapid extraction method”, atomic absorption method, conductivity method, distilled water oscillation method, ultraviolet spectroscopy, etc. The methods are used for certain types of products. test method.

Principle of the Wool Fiber Oil Content Test Method

- Standard extraction method: The principle of the standard extraction method is to use the oil that can be dissolved in a specific organic solvent, extract the oil in the sample with the appropriate organic solvent through the fat extractor, and then evaporate the solvent to dryness and weigh. The quality of the residual oil and the quality of the sample are calculated to obtain the oil content of the sample.

- Neutral soap washing method: The principle of neutral soap washing method is to use the affinity between soap and oil, and under the action of washing force, the oil on the sample is transferred to the soap, and then Calculate the oil content of the sample according to the mass change of the sample before and after washing.

- Optical refractive index method: The principle of optical refractive index method is to use the method of measuring the critical angle of total reflection to measure the refractive index of an unknown substance, and to quantitatively analyze some components in the solution to test the purity of the substance”.

- Low-field NMR method: The principle of NMR method is to use NMR spectroscopy to transmit a pulsed magnetic field to the fiber sample. When the magnetic field is canceled, the response magnetic signal of the sample is detected, because the signal emitted by the fiber is higher than that of the oil. The decay is fast, and the oil content of the sample can be converted from the difference between the two.

Advantages of Low-field NMR to Determine the Oil Content of Wool Fibers

Most of the traditional fiber oil content detection methods use extraction methods; there are limitations such as long detection time, delayed detection results, the need to use harmful reagents, high labor costs, and experience errors. In view of the shortcomings of traditional methods, Niumag developed a method to test the oil content of fibers using low-field NMR.

Performance Characteristics: Fast, Precise, Non-destructive.

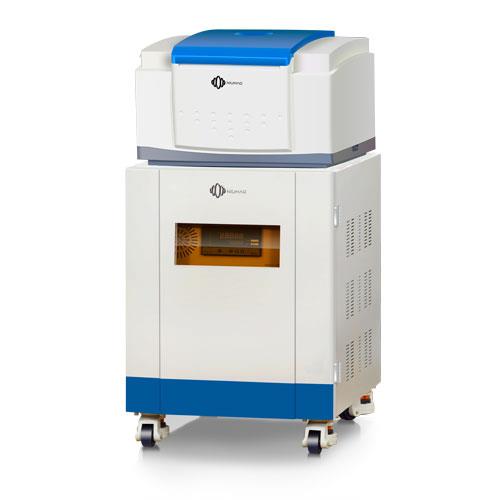

NIUMAG Fiber Oil Content NMR Analyzer

Only 30 seconds, fast response, meet the needs of large sample testing, and provide the possibility for online real-time quality control

National standard method – NMR method to ensure accurate measurement, non-destructive, environmental protection, longitudinal experiments can be carried out.

NIUMAG

NIUMAG