Acabado de giro Análisis por RMN

Acabado de giro NMR Background

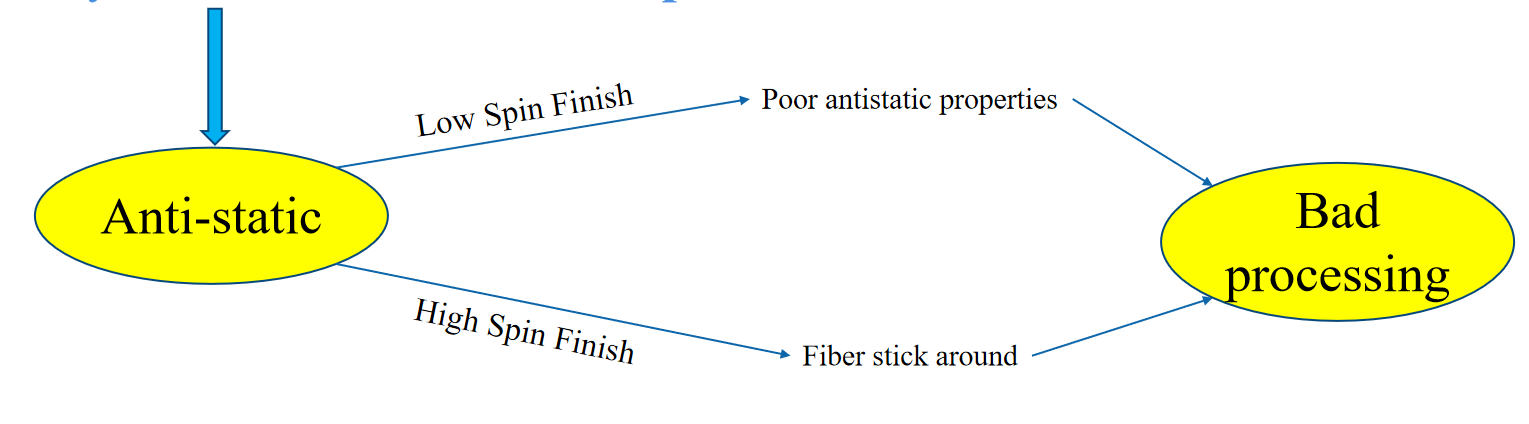

The primary purpose of acabado de giro is to facilitate the smooth and efficient processing of fibers during spinning. It helps to reduce friction and static electricity, which can otherwise cause the fibers to break or become tangled. By lubricating the fibers, acabado de giro allows them to slide past each other more easily, resulting in a higher quality and more consistent yarn. acabado de giro plays a vital role in the textile industry by enhancing the spinning process and ensuring the production of high-quality yarns or threads.

Acabado giratorio detection is crucial for maintaining product quality, optimizando los costos de producción, mejorando la eficiencia del proceso, y garantizar el cumplimiento de los estándares de la industria. By accurately monitoring and controlling acabado de giro levels, Los fabricantes pueden mejorar sus operaciones., minimizar el desperdicio, and produce high-quality textiles that meet customer expectations and regulatory requirements.

Acabado giratorio Importancia

Acabado giratorio detection is an important process in the textile industry for several reasons:

Control de calidad: Acabado giratorio detection helps ensure the quality and performance of the final textile product. If excessive acabado de giro is present on the fibers, it can negatively impact subsequent processes like dyeing, impresión, or finishing. Detection allows manufacturers to identify and rectify any issues before further processing, leading to improved product quality and customer satisfaction.

Cost Optimization: Acabado giratorio detection helps optimize production costs. Applying acabado de giro can be an expensive process, as it involves the use of chemicals and additional machinery. By accurately detecting the presence and quantity of acabado de giro on fibers, manufacturers can adjust and optimize the application process to minimize waste and reduce costs.

Process Efficiency: Detection of acabado de giro helps in monitoring and controlling the spinning process itself. If the application of acabado de giro is inconsistent or inadequate, it can result in uneven lubrication and subsequently impact the spinning performance. By detecting and rectifying such issues promptly, manufacturers can improve process efficiency, reduce downtime, and achieve higher production yields.

Environmental Considerations: Acabado giratorio detection also has environmental implications. Excessive acabado de giro residue on fibers can lead to increased pollution and wastewater contamination during subsequent processes. By accurately detecting acabado de giro levels, manufacturers can implement appropriate measures to minimize the release of harmful substances into the environment, contributing to sustainable and responsible textile production.

Compliance with Standards and Regulations: Textile products often need to comply with certain industry standards and regulations related to safety, actuación, and environmental impact. Acabado giratorio detection helps ensure that the final products meet these requirements by controlling the quantity of acabado de giro applied and removing any excess that may be harmful or non-compliant.

En general, acabado de giro detection is crucial for maintaining product quality, optimizando los costos de producción, mejorando la eficiencia del proceso, y garantizar el cumplimiento de los estándares de la industria. By accurately monitoring and controlling acabado de giro levels, Los fabricantes pueden mejorar sus operaciones., minimizar el desperdicio, and produce high-quality textiles that meet customer expectations and regulatory requirements.

Acabado de giro Análisis por RMN

Resonancia magnética nuclear (RMN) is a technique that can be used to detect and analyze acabado de giro on fibers. NMR spectroscopy is a powerful tool for studying the molecular structure, composición, and properties of various substances, incluido acabados giratorios.

En el contexto de acabado de giro detection, NMR can provide valuable information about the chemical composition of the acabado de giro solution and its interaction with the fibers. By analyzing the NMR spectrum of the fibers, researchers can identify specific signals corresponding to the acabado de giro components present on the surface.

NMR-based acabado de giro detection offers a non-destructive and highly sensitive approach to analyzing the presence, composición, and distribution of acabados giratorios on fibers. It provides valuable information for process optimization, control de calidad, and understanding the interaction between acabado de giro and fibers in the textile industry.

NIUMAG NMR Spin-Finish Analyzer Benchtop NMR Analyzer Fiber PQ001

mohoso

mohoso