Spin Finish Measurement by NMR

Spin finish measurement Background

Spin finish measurement is a critical quality control parameter in the textile industry as it directly determines whether the fibers meet the required specifications for their intended use. Uneven spin finish distribution is a common issue in chemical fiber production. Fibers with low oil content are prone to static electricity, while those with high oil content are more likely to tangle, both of which can significantly impact the textile processing process. Therefore, it is essential to accurately and quickly measure the oil content of fibers to effectively monitor and control the amount of spin finish.

Spin Finish Measurement Methods

Various test methods are specified in the GB/T 6504–2008 “Chemical Fiber Oil Content Test Method,” including the extraction method, neutral soap washing method, optical refractive index method, and nuclear magnetic resonance (NMR) method. Additionally, to streamline production, some companies have developed alternative test methods such as the rapid extraction method, atomic absorption method, conductivity method, distilled water oscillation method, and ultraviolet spectroscopy, which are tailored for specific product types.

The principles of some commonly used spin finish test methods are as follows:

- Standard extraction method: This method involves dissolving the oil that can be dissolved in a specific organic solvent, extracting the oil from the sample using an appropriate organic solvent through a fat extractor, evaporating the solvent to dryness, and weighing the residue. Based on the oil quality and sample quality, the oil content of the sample is calculated.

- Neutral soap washing method: This method utilizes the affinity between soap and oil. Under the influence of washing force, the oil on the sample is transferred to the soap, and the oil content of the sample is then determined by measuring the change in sample weight after washing.

- Optical refractive index method: This method measures the refractive index of an unknown substance using the critical angle of total reflection. By quantitatively analyzing certain components in the solution, the purity of the substance can be determined.

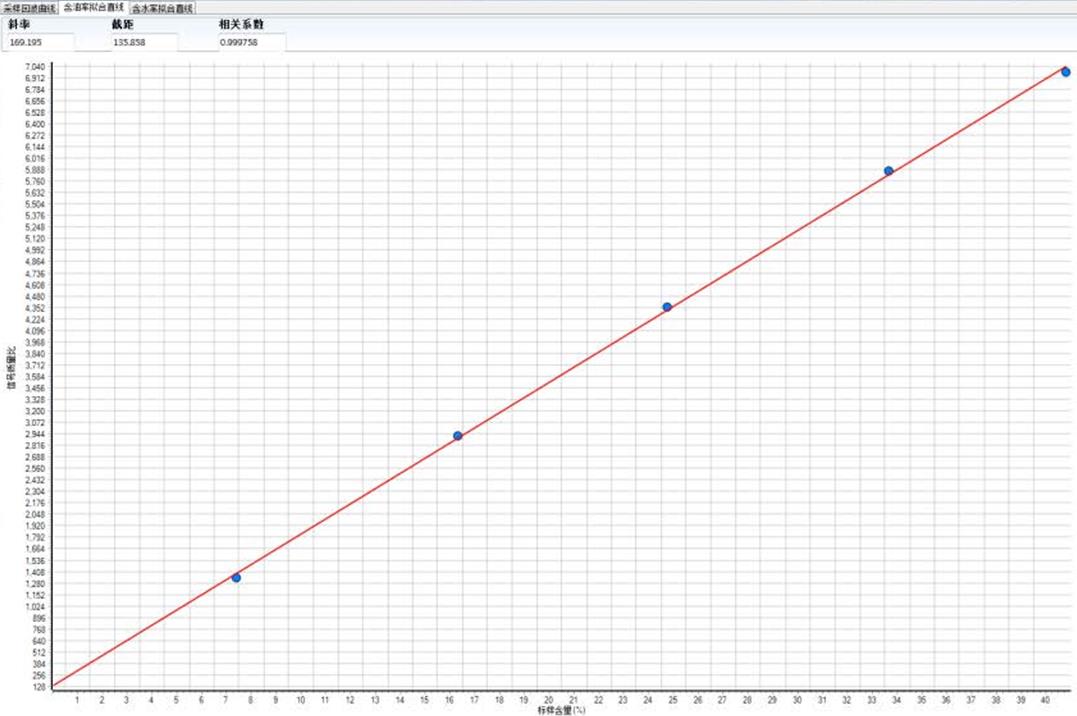

- Low-field nuclear magnetic resonance method: The NMR method employs NMR spectroscopy to apply a pulsed magnetic field to the fiber sample. The response magnetic signal of the sample is detected when the magnetic field is canceled. As the signal emitted by the fiber decays faster than that of the oil, the difference between the two can be used to calculate the oil content of the sample.

Advantages of Spin Finish Measurement by NMR

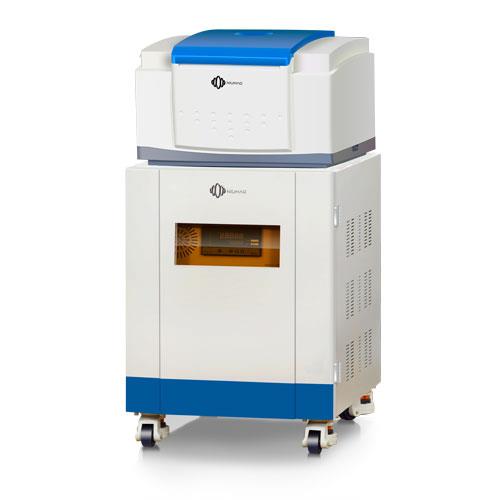

Among these methods, the low-field NMR method offers several advantages for spin finish analysis. Most traditional detection methods for fiber oil content rely on extraction methods, which are time-consuming, yield delayed results, require the use of potentially harmful reagents, incur high labor costs, and are subject to empirical errors. In response to these limitations, NIUMAG has developed a low-field NMR method for spin finish testing.

Key performance characteristics of low-field NMR method include its speed, accuracy, and non-destructiveness. In just 30 seconds, precise spin finish data can be obtained, providing the possibility for online real-time quality control.

This innovative approach to spin finish measurement addresses the shortcomings of traditional methods, offering a faster and more efficient solution that ensures accurate data collection and facilitates effective quality control in textile production.

NIUMAG NMR Spin-Finish Analyzer – Benchtop NMR Analyzer Fiber PQ001

NIUMAG

NIUMAG