Low field NMR Study on Degree of Cross-link Rubber

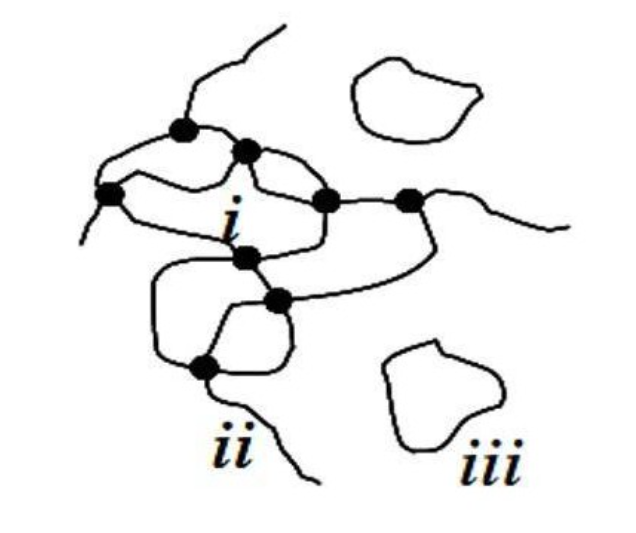

Cross-linking, also referred to as the degree of cross-link, is commonly quantified through cross-link density, which represents the average molecular weight between adjacent cross-link points or the number of cross-link points per cubic centimeter. It serves as a critical factor in determining the properties of rubber materials. Specifically, the degree of cross-linking impacts the elasticity of rubber.

Rubber with a lower degree of cross-linking exhibits enhanced elasticity. This is because the presence of fewer cross-link points allows the rubber chains to move more freely, facilitating greater stretchability and flexibility. Such rubber can be deformed easily and is characterized by a higher degree of resilience.

On the other hand, rubber with a higher degree of cross-linking tends to possess inferior elasticity. The increased number of cross-link points restricts the movement of rubber chains, making it harder for the material to deform or stretch. As a result, the rubber becomes stiffer and less capable of recovering its original shape after being stretched or compressed.

The degree of crosslinking in rubber has long posed challenges within the industry. Traditional methods, such as the swelling method, often suffer from low test accuracy and are susceptible to significant subjective influences. However, the utilization of low filed NMR technology presents a promising alternative for assessing crosslinking density with improved accuracy and non-destructive analysis.

In low filed NMR, the decay curve of polymer relaxation undergoes changes corresponding to the internal components of the sample. By employing NMR relaxation techniques, it becomes possible to rapidly and non-destructively obtain signals from both crosslinked and non-crosslinked chains, thus determining the degree of crosslinking.

The solvent component within the polymer exhibits strong fluidity and relatively slow decay in the relaxation process. Non-crosslinked segments possess certain molecular motion characteristics, resulting in a slower decay rate. Conversely, crosslinked segments experience significant binding, leading to limited molecular motion and faster decay. By leveraging the differences in decay characteristics, NMR relaxation technology can distinguish between these segments and provide valuable insights into the degree of crosslinking.

Low Field NMR Principle of Studing Rubber Crosslinking

To further enhance the accuracy of crosslinking density measurements, a new sequence acquisition technique known as MSE-CPMG (Multi-Spin Echo Carr-Purcell Meiboom-Gill) can be employed. This technique involves applying combined pulses, causing the NMR signal to reverse back and forth within the dead time range. This process helps maintain the original NMR signal intensity as much as possible while collecting shorter relaxation information. The utilization of the MSE-CPMG sequence acquisition method contributes to the refinement of crosslinking density testing, leading to enhanced accuracy and reliability compared to traditional SE (Spin Echo) or CPMG (Carr-Purcell Meiboom-Gill) sequence acquisition methods.

By leveraging NMR relaxation technology and employing advanced acquisition sequences like MSE-CPMG, the industry can overcome the limitations of traditional methods. This enables more precise assessment of the degree of crosslinking in rubber, facilitating better control over the production process and ensuring the desired material properties are achieved.

Low field NMR analysis technology leverages pulses to excite hydrogen protons within material samples, causing them to resonate. Following the pulse excitation, the hydrogen protons undergo relaxation, during which their relaxation times differ depending on the various states within the sample. By detecting and analyzing the relaxation signals, it becomes possible to directly or indirectly assess specific properties of the material.

In the context of crosslinking analysis, low field NMR method utilizes low field NMR analysis technology to evaluate the movement of hydrogen (H) molecules along the hydrocarbon chain. By employing a relaxation analysis model, the method allows for the determination of the crosslinking degree of the sample.

One of the key advantages of low field NMR analysis is its non-invasive nature. The test process does not require the use of chemicals, and it does not cause any damage to the sample being analyzed. Moreover, the test speed is relatively fast, with the typical duration being completed within 3 minutes.

Low field NMR analysis technology provides a convenient and efficient means to assess material properties, particularly in evaluating the crosslinking degree of samples. Its non-destructive and rapid testing capabilities make it a valuable tool for quality control, research, and development in various industries.

NIUMAG Low Field NMR Analyzer – VTMR20-010V-I

The VTMR20-010V-I integrates various relaxation time testing and magnetic resonance imaging technology, combined with the variable temperature module, it can provide a wide range of solutions, which can carry out non-destructive rapid analysis of samples such as solutions, gels, solids, particles

NIUMAG

NIUMAG