Benchtop NMR Instrument Apply in Textiles

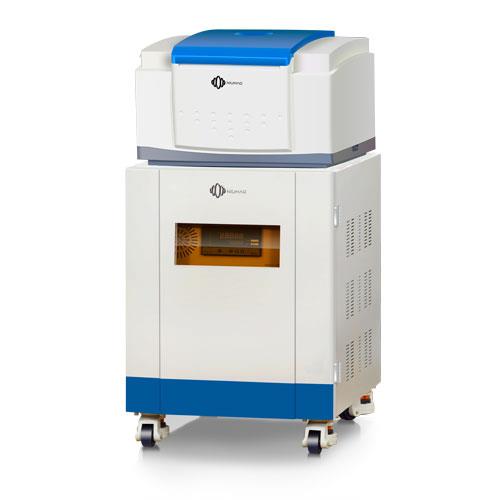

In NMR Industrail solution, Niumag Benchtop NMR has PQ001 Series which is widely applied in Textiles industry.

Coated fabrics are fabrics or fabrics that have been treated with a special process. Mainly, on the basis of the cloth, special technology is used to coat materials with special functions, so that the cloth adds special functions. Therefore, it is also called functional coated fabric or cloth.

Fluorinated coatings are commonly used in fibers and textiles to provide oil resistance, water resistance, ease of cleaning and flame retardant properties. Can be used in carpets, outdoor products, and performance apparel. The control of the amount of fluorinated coating is very critical. Controlling the content of fluorinated coating can optimize the process and improve the performance of the product. Benchtop NMR can be used for fast, simple, and accurate measurements of fluorinated coatings.

Benchtop NMR Measurement Fundamentals of Fluorinated Coatings on Fibers and Textiles:

The benchtop NMR analysis technique is based on the direct measurement of the nuclear magnetic resonance (NMR) signal of fluorine 19. Since the fluorine content is proportional to the intensity of the detected NMR fluorine signal, the fluorine content (wt%) can be calculated using an appropriate calibration curve.

Benchtop NMR Measurement Methods for Fluorinated Coatings on Fibers and Textiles:

After calibrating with 3~6 samples with known fluorine content, unknown samples can be tested within 30~3 minutes. The benchtop NMR testing process is fast and non-destructive, enabling industrial online process testing.

Compared to chemical methods, benchtop NMR has better reproducibility, does not require chemical solvents, and can be performed by untrained personnel.

Fiber oiling rate is an important quality control parameter, which directly determines whether the fiber can meet the requirements of use. Uneven oil content is a common problem in chemical fiber production. Fibers with low oil content are prone to static electricity, while fibers with high oil content are prone to entanglement, both of which will seriously affect the normal process of textile processing. Therefore, it is very important to measure the oil content of fiber accurately and quickly to grasp and control the oil amount.

- Standard extraction method: The principle of the standard extraction method is to use the oil that can be dissolved in a specific organic solvent, extract the oil in the sample with the appropriate organic solvent through the fat extractor, then evaporate the solvent to dryness, and weigh the residue. According to the quality of the oil and the quality of the sample, the oil content of the sample is calculated.

- Neutral soap washing method: the principle is to use the affinity of soap and oil. Under the action of washing force, the oil on the sample is transferred to the soap, and then the sample is calculated according to the quality change of the sample after washing. oil content.

- Optical refractive index method: The principle of optical refractive index method is to use the method of measuring the critical angle of total reflection to measure the refractive index of an unknown substance, and to quantitatively analyze some components in the solution to test the purity of the substance.

- Benchtop NMR method: The principle of NMR method is to use NMR spectroscopy to transmit a pulsed magnetic field to the fiber sample. When the magnetic field is canceled, the response magnetic signal of the sample is detected, because the signal emitted by the fiber is higher than that of the oil. The decay is fast, and the oil content of the sample can be converted from the difference between the two.

Advantages of benchtop NMR Method:

1. Compared with the traditional method, the benchtop NMR measurement has much better repeatability and reproducibility;

2. The calibration of the benchtop NMR measuring instrument is simple;

3. Benchtop NMR measurement can be used for oil and water content testing in other chemical products;

4.The benchtop NMR measurement function is powerful, suitable for the fluorine content test of fiber and textile products;

5. The benchtop NMR measuring instrument is easy to operate, does not require technical personnel, and is easy to operate by untrained personnel;

6. The benchtop NMR measurement test is fast;

7. The benchtop NMR measurement has no requirements on the shape of the sample, and the sample can be powder, granule, film or block.

8. The benchtop NMR measurement is a non-invasive and non-destructive test, and the same sample can be repeatedly measured as needed;

9. Benchtop NMR measurement can be used for quality inspection and quality control in the industrial production process, saving labor and significantly improving efficiency;

10. Benchtop NMR measurement can be used for 1H content testing in some raw materials and chemical products;

11.The NMR signal of benchtop NMR measurement is generated by all hydrogen nuclei in the entire sample volume, and the test result does not depend on the sample surface or sample color;

NIUMAG Benchtop NMR for Textiles Analysis – PQ001

NIUMAG

NIUMAG