Low field NMR relaxation technique used to detect in situ dispersion of CMP polishing fluid

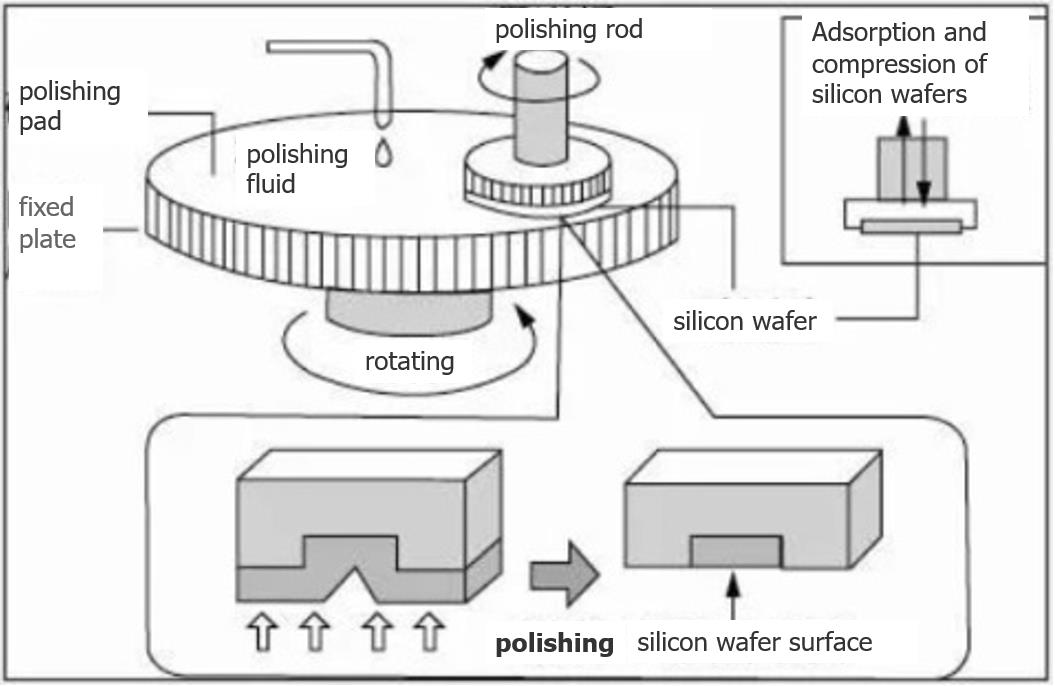

CMP stands for Chemical Mechanical Polishing. This technology is one of the necessary processes for semiconductor wafer manufacturing, which is very important for high precision and high performance wafer manufacturing. The main components of polishing fluid include abrasive particles, PH regulator, oxidant, dispersant and so on. From the composition, we can roughly know that the polishing fluid is a kind of nanomaterial suspension with high requirements for dispersion, so the size change of particles and the dispersion of particles in the suspension have extremely strict requirements in the grinding process.

Low field NMR relaxation technique is used to detect particle size change and particle dispersion in suspension

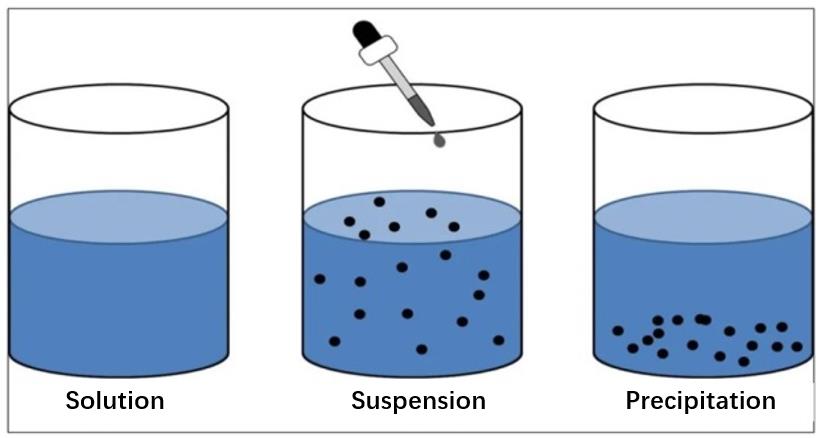

Low field NMR relaxation technology can detect the state change of water molecules in suspension system in real time by using water molecules (solvents) as probes.

Low field NMR relaxation technique can distinguish the thin layer of solvent molecules on the surface between the solid-liquid interface of nanoparticles and the solvent. When the size or dispersion of particles changes, the solvent molecules on the surface of particles also change accordingly. Low field NMR relaxation technology can detect such changes sensitively, so as to rapidly evaluate the dispersion of polishing fluid and related suspension samples and the change process of particle size in suspension.

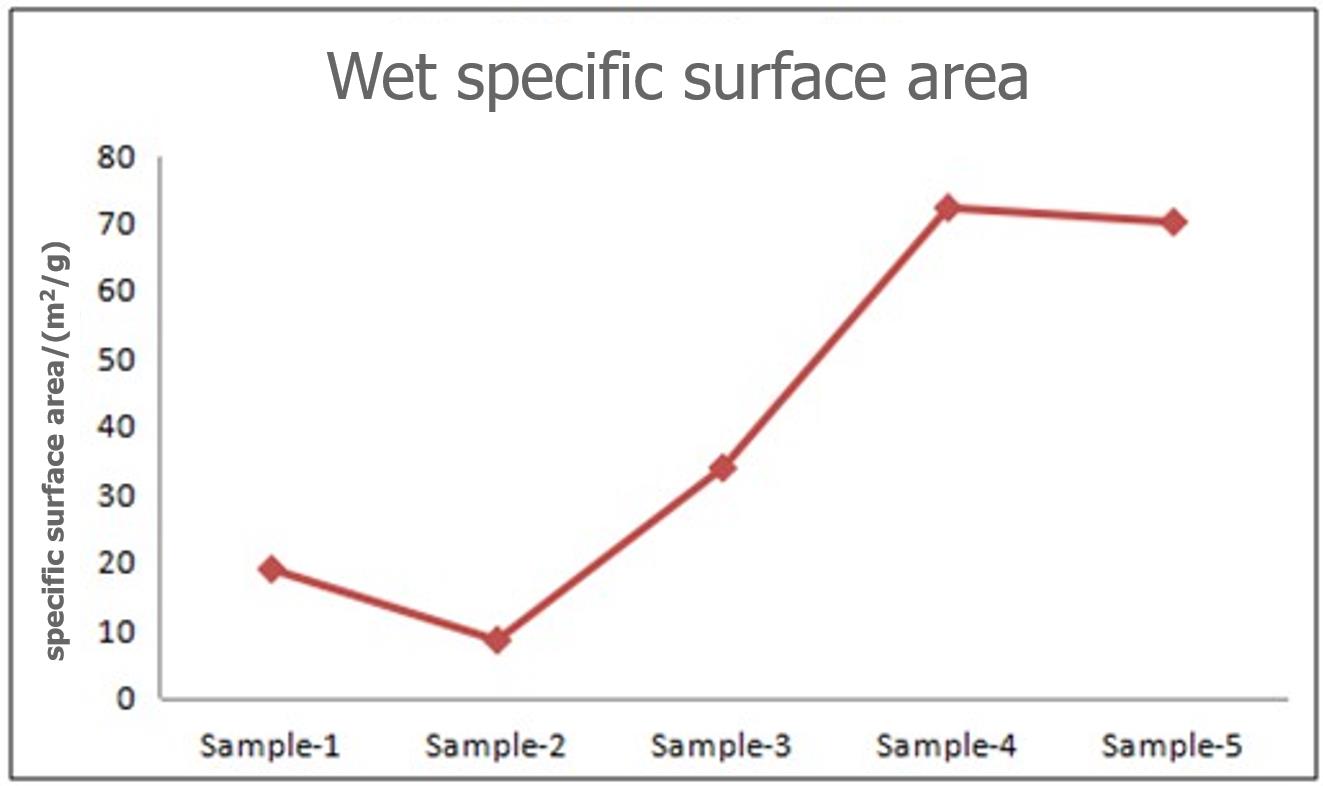

What are the differences between low field NMR relaxation and traditional nitrogen adsorption?

Before the low field NMR relaxation technique was applied to the polishing fluid field, nitrogen adsorption was the most commonly used method to characterize the specific surface area of particles. However, in the actual development and production process, researchers found that even though the specific surface area of the abrasive particles characterized by nitrogen adsorption method is very stable, the performance of the polishing solution is still unstable during the polishing process. This situation is likely to be the abrasive particles in the solvent system in the agglomeration, and then change in size, resulting in the final grinding performance of the problem. The low field NMR relaxation technique can be directly used to detect the dispersion of abrasive stock, and can quickly evaluate the dispersion of suspension system, so it is widely used in the development and production control of CMP polishing fluid.

Where else can low-field NMR relaxation be used?

Low field nuclear magnetic relaxation technology is not only used in semiconductor CMP polishing fluid, but also can be used in the new energy battery paste, conductive silver paste, graphene paste, electronic paste and other new material fields supported by the Chinese government. These directions are very suitable for studying the dispersibility and stability of the stock solution by low field NMR relaxation technique.

NIUMAG

NIUMAG