Effects of fractures on recovery of low permeability rocks: a low field NMR study

1、Influence of fractures on recovery of low permeability rocks – Abstract

Hydraulic fracturing technology can increase oil production in tight formations. The influence of fractures on rock pore recovery is the focus of the study. The pore structure of rock changes during fracturing, especially during fracture manufacturing in laboratory, which affects the mass transfer between matrix pores and fractures. These changes need to be taken into account to accurately assess the impact of fractures on pore fluid migration. Direct comparisons of samples before and after fracturing can lead to misleading conclusions. In this study, heavy water and guar gum were used to configure the fracture filling material, which did not invade matrix pores and did not generate detectable NMR signals. The NMR characteristics of cracks can be obtained by testing samples filled with this new material and comparing the measured data of unfilled samples. In the follow-up N2 and CO2 huff and puff experiments, they were isolated to eliminate the influence mechanism of fractures on fluid transport in pore-fracture binary system.

(Low field NMR analysis) experimental results show that:

1) The sweep efficiency of gas is reduced by fractures, which can be partially alleviated by injecting N2 instead of CO2. N2 can support small pores flexibly, but the total recovery of pure N2 is significantly lower than that of CO2.

2) Filling fractures increases pore recovery.

2、Apparatus and Methods

The Niumag low field NMR core analysis system (medium size NMR imaging analyzer) used in this study is shown in Figure 1.

Figure 1. Medium-size NMR analyzer (Low field NMR core analysis system)

The process of gas injection and displacement is monitored by low field NMR.

1) Gas huff and puff experiment of saturated oil matrix samples (Dong, 2020A,2020b)

2) Gas huff and puff test of fracturing samples, Brazilian splitting method (BDM) for fracture construction, saturated oil to determine the total pore distribution after fracturing.

3) Gas huff and puff experiment of filling fracture samples. Heavy water and guar gum are configured with crack filler to determine the distribution and content of cracks.

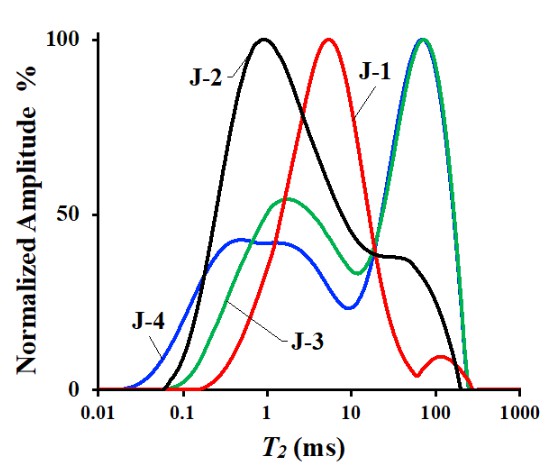

Initial NMR T2 curves of the four samples are shown in Figure 2.

Figure 2. T2 spectrum of saturated light oil of samples before fracturing (J-1 and J-2 are taken from Jimsar sag, and J-3 and J-4 from Xihu sag)

3、Results

1) Pressure fracture distribution (low field NMR analysis)

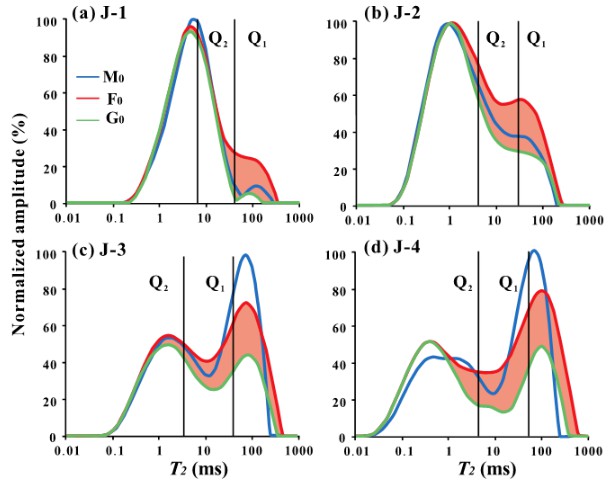

The complete T2 distribution of fracture openings were obtained through guar gum filling experiment (orange filling area of T2 spectrum, Figure 3). Some large fractures were added to the right side of T2 spectrum, and small fractures could extend to T2=1ms. Fracturing alters the matrix pore structure (M0 vs. G0), varying the magnitude and boundaries of the matrix pores. Therefore, the identification of fracture and matrix pore distribution is helpful to accurately evaluate the effect of fracture on fluid migration.

Figure 3. T2 distribution of fractures (Q1 and Q2 are the boundaries between large and small pores)

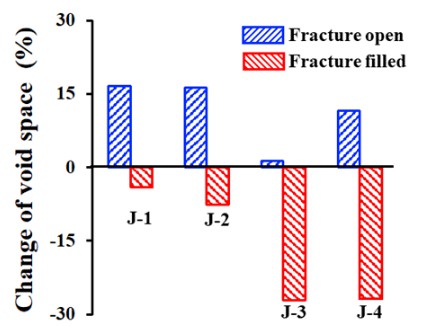

2)Pore growth before and after fracturing

The pore change rate before and after fracture filling was calculated (Figure 4). PVF (blue) reflects the improvement effect of fracturing on total pores, and PVG (red) reflects the amount of matrix pores converted into fractures. The improvement of pore volume of microporous rock samples (J-1 and J-2) is more obvious, but the ratio of matrix pores to fractures is low. On the contrary, the improvement effect of total pore volume in macroporous rock samples (J-3 and J-4) is general, but the ratio of matrix pore to fracture is high. PVF was obtained by comparing M0 and F0 cumulative NMR signal, and PVG was obtained by comparing M0 and G0 cumulative NMR signal.

Figure. 4. Pore change rate before and after fracture filling

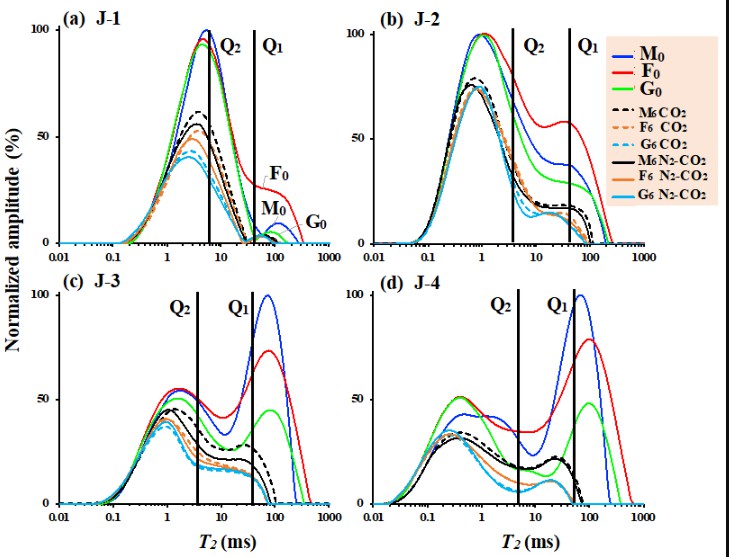

3) Influence of fracture filling on flow (low field NMR analysis)

Fracturing changes the matrix pore structure, and the pore size classification method based on the original sample is no longer applicable. In this paper, the pores are divided into three types of large, medium and small pores by fracture size quantile to calculate pore occurrence (such as medium pore Q1).

Figure. 5 T2 spectrum of gas injection huff and puff of fractured rock sample (‘G6 N2-CO2’is the sixth round N2-CO2 huff and puff spectrum of fractured rock sample G0)

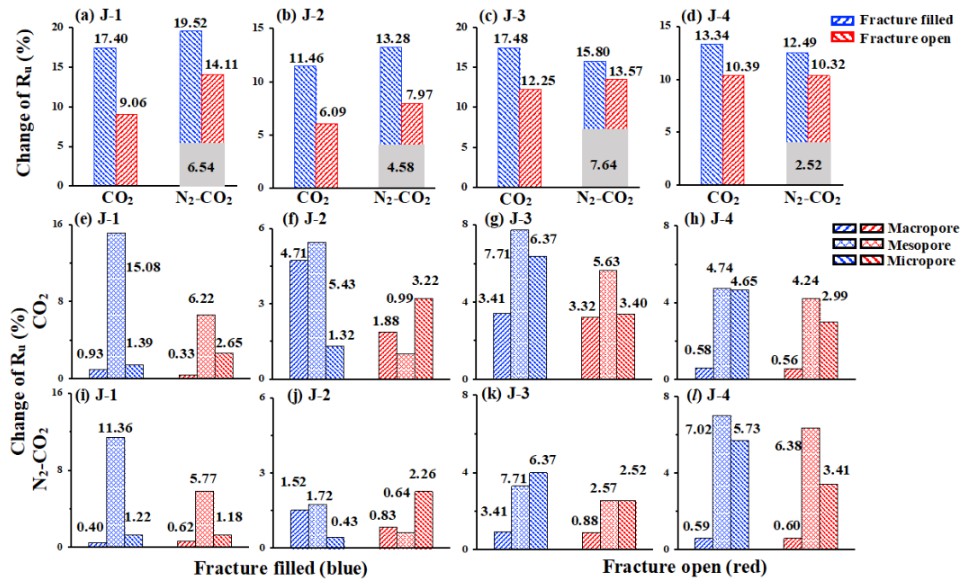

Using the M0 recovery before fracturing as the base value, the increased production Ru under fracture and gas combination was compared (Figure 6). The effect of injecting N2-CO2 into matrix M0 was better than that of pure CO2 (Gray, Dong, 2020A). Compared with pure CO2 huff and puff mode, N2-CO2 injection in fractured samples has a good effect in microporous rock samples (J-1 and J-2), but a poor effect in macroporous rock samples (J-3 and J-4), which is speculated to be related to the elastic support effect of N2 molecule on pore. Fractures store large amounts of gas, especially CO2, which weakens the diffusion kinetic energy of gas through the matrix pores, resulting in a decrease in total recovery (red). Fracture packing can increase the sweep efficiency of gas in matrix pores and increase recovery (blue). In the short term, cracking can greatly increase the yield. However, the gas storage of the seam will have a negative effect on long-term development.

Figure. 6. Increased recovery under fracture filling and gas injection combined mode

Related literature (low field NMR analysis) :

1)Dong Xu, Shen Luyi*, Golsanami Naser, Liu Xuefeng, Sun Yuli, Wang Fei, ShiYing, Sun Jianmeng. How N2 injection improves the hydrocarbon recovery of CO2HnP: An NMR study on the fluid displacement mechanisms. Fuel. 2020a. 278:118286.

2)Dong Xu, Shen Luyi*, Liu Xuefeng, Zhang Pengyun, Sun Yuli, Yan Weichao, SunJianmeng. NMR characterization of a tight sand’s pore structures and fluidmobility: An experimental investigation for CO2 EOR potential. Marine and Petroleum Geology. 2020b.118:104460.

3)Liu Xuefeng, Dong Xu*, Golsanami Naser, Liu Bo, Shen Luyi W., Shi Ying, GuoZongguang. NMR characterization of fluid mobility in tight sand: Analysis onthe pore capillaries with the nine-grid model. Journal of Natural Gas Science and Engineering. 2021. 94.

NIUMAG

NIUMAG