“MicroMR” is a new type of nuclear magnetic resonance imaging NMR analyzer that has both analyzing and imaging functions. It is more accurate and more stable than the old types. Comparing to the old types, it has following advantages. Firstly, it has an independent Pulse Sequence Generator (PSG) that can control pulse sequence precisely and stably. Secondly, it has both Radio Frequency (RF) transmitting circuit and RF receiving circuit, which can enhance the signal-to-noise ratio of Nuclear Magnetic Resonance (NMR) signals. Lastly, it has a temperature control system with high accuracy, which guarantees the repeatability of measurement.

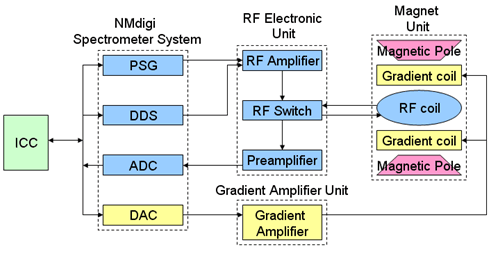

The following is the framework of benchtop NMR

Fig 1:The framework of NIUMAG benchtop NMR

According to the function, bench top NMR can be divided into five parts: Industrial Control Computer (ICC) with NMdigi Spectrometer System, RF Electronic Unit (RFEU), Gradient Amplifier Unit (GAU), Magnet Unit (MU) and Power Supply Unit (PSU). ICC is the brain of the machine. It receives instructions from users and controls other units to execute tasks. Also it finishes other tasks such as data processing, image rebuilding etc. RFEU transmits RF signals and receives NMR signals both by RF coil. GAU supplies gradient magnetic field. MU generates homogeneous magnetic field.

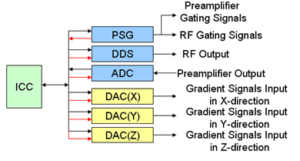

NMdigi Spectrometer System

Fig 2:The inner framework of bench top NMdigi Spectrometer System

NMdigi Spectrometer System comprises one PSG, one DDS, one ADC and three DACs. These circuit boards are inserted in the PCI slots of ICC. The inner framework of NMdigi spectrometer system is illustrated in Fig 2. PSG controls DDS, ADC and DACs. It also sends gating signals to RFEU. DDS produces RF signals in specific shape for RFEU. ADC transforms the NMR signals from analogue form to digital form. DACs transform the gradient parameters into equal electric currents.

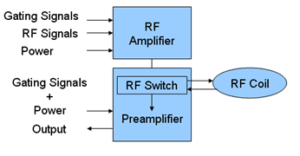

RF Electronic Unit

Fig 3:The inner framework of benchtop NMR RF Electronic Unit

RF amplifier amplifies the RF pulses sent by NMdigi spectrometer system and then the pulses are sent into RF coil. Preamplifier amplifies the NMR signals received from RF coil and then sends the signals to ADC of NMdigi spectrometer system. RF switch decides when the signals are transmitted and when the signals are received.

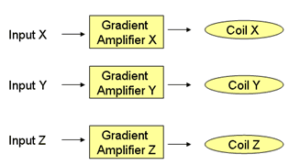

Gradient Amplifier Unit

Fig 4:The inner framework of Bench top NMR Gradient Amplifier Unit

Under the control of PSG, the three(X, Y, Z) routes of currents which are transformed by DACs are sent to the gradient amplifiers and then are sent to gradient coils for producing the gradient magnetic field.

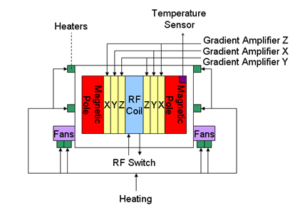

Magnet Unit

Fig 5:The inner framework of Bench top NMR Magnet Unit

Magnet Unit consists of one magnet, three sets of gradient coils, one RF coil, one temperature sensor, four heaters and two fans. As illustrated in Fig 1-5, the magnet has two poles. The gradient coils(X, Y and Z) are stuck to the two poles. The temperature sensor is pasted on one of the poles. Two of heaters are adhered to the surface of the magnet and the other two are adhered to the surface of the fans.

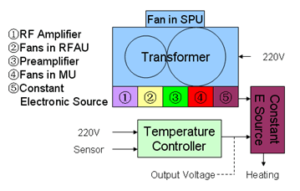

Power Supply Unit

Fig 6:The inner framework of bench top NMR Power Supply Unit

Power Supply Unit is chiefly composed of power supply, temperature controller and constant current source. The transformer in Fig 6 transforms consumer voltage 220V into all kinds of working voltage needed by other units such as RF amplifier’s working voltage(24V), fan’s of PSU(12V), preamplifier’s(±5V), fans’ of MU(12V), and constant current source’s(20V). The temperature controller and the constant current source together construct the temperature control system. Firstly, the controller chooses a heating mode based on the temperature which sensor sends back. Secondly, the controller sends the proper heating voltage to the constant current source. Lastly, constant current source changes the voltage into current and sends to the heaters. And this is one circulation of heating process. To keep the stable temperature in MU, this process is circulating all the time.

NIUMAG

NIUMAG