Spin Finish Measurement by Low Field NMR

Oil applied to fibers serves multiple essential purposes, primarily functioning as a lubricant and an antistatic agent. Additionally, it plays a crucial role as a carrier for various chemical agents, including fiber bactericides, flame retardants, and colorants. The spin finish of fibers stands out as a pivotal quality control parameter that directly determines the fiber’s suitability for its intended purpose. However, achieving uniform spin finish distribution remains a frequent challenge in the chemical fiber production process.

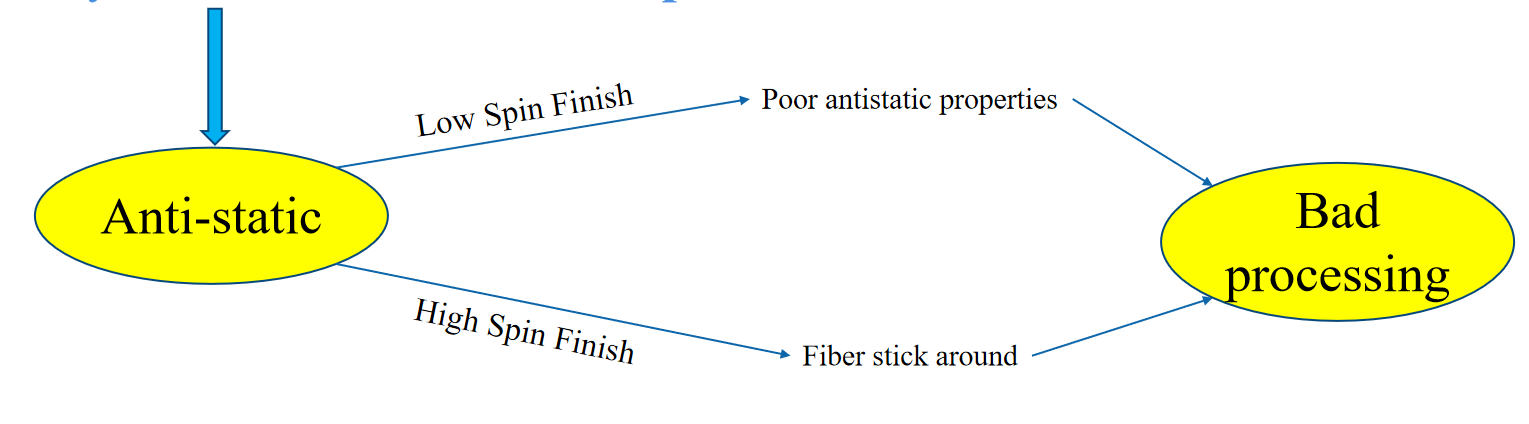

Fibers with insufficient spin finish are susceptible to static electricity, while those with excessive spin finish are prone to tangling, both of which can significantly disrupt the textile manufacturing process. Consequently, precise measurement of spin finish becomes paramount for an accurate assessment and effective control of this crucial parameter.

Spin Finish Measurement Methods

Test methods for assessing the spin finish of wool fibers encompass various techniques. The current standard, GB/T 6504-2008, outlines several established methods, including the standard extraction method, neutral soap washing method, optical refractive index method, and nuclear magnetic resonance method.

To streamline production processes, Sinopec has introduced several innovative test methods. These include the ‘rapid extraction method,’ atomic absorption method, conductivity method, distilled water oscillation method, and ultraviolet spectroscopy. These alternative methods are tailored to specific product types, offering flexibility in spin finish evaluation.

Principle of the Wool Fiber Spin Finish Measurement Method

Optical Refractive Index Method: This method employs total internal reflection to measure the refractive index of an unknown substance. It involves quantitatively analyzing certain components in the solution to assess substance purity, which aids in determining the spin finish of the sample.

Neutral Soap Washing Method: The neutral soap washing method capitalizes on the affinity between soap and oil. By applying washing force, the oil on the sample is transferred to the soap. The spin finish of the sample is then determined by assessing the mass change of the sample before and after washing.

Standard Extraction Method: This method operates on the principle of dissolving oil that can be dissolved in a specific organic solvent. It involves extracting the oil from the sample using an appropriate organic solvent in a fat extractor. Subsequently, the solvent is evaporated to dryness, and the remaining oil’s weight is measured. By comparing the weight of the residual oil to the initial sample weight, the spin finish of the sample is calculated.

Low-Field NMR Method: The Low-Field NMR (Nuclear Magnetic Resonance) method utilizes NMR spectroscopy to transmit a pulsed magnetic field to the fiber sample. When the magnetic field is canceled, the response magnetic signal of the sample is detected. Because the signal emitted by the fiber decays more rapidly than that of the oil, the spin finish of the sample can be derived from the difference between the two signals.

The Advantages of Low-Field NMR Method

Accuracy: This method offers precise measurements. It can distinguish between the spin finish and the fiber itself, providing accurate data on the spin finish content without being influenced by other factors.

Speed: Low-field NMR provides rapid results. Unlike traditional extraction methods that may involve time-consuming processes such as solvent extraction and evaporation, NMR measurements are typically quicker, reducing overall detection time.

Non-Destructive: Low-field NMR is a non-destructive technique. Unlike some traditional methods that consume the sample or alter its properties during testing, NMR allows for the preservation of the original sample, which can be beneficial for further analysis or quality control.

No Harmful Reagents: Traditional methods often require the use of potentially harmful reagents or chemicals. In contrast, NMR is based on magnetic resonance, making it a safer and more environmentally friendly option.

Minimized Experience Errors: Traditional methods can be subject to errors due to variations in operator experience and technique. Low-field NMR provides consistent and objective measurements, minimizing the impact of operator-related errors.

Reduced Labor Costs: The streamlined and automated nature of NMR testing can reduce labor costs associated with sample preparation and handling, as well as the need for extensive manual intervention.

NIUMAG

NIUMAG