Pulsed NMR Detection Method of Fiber Oiling

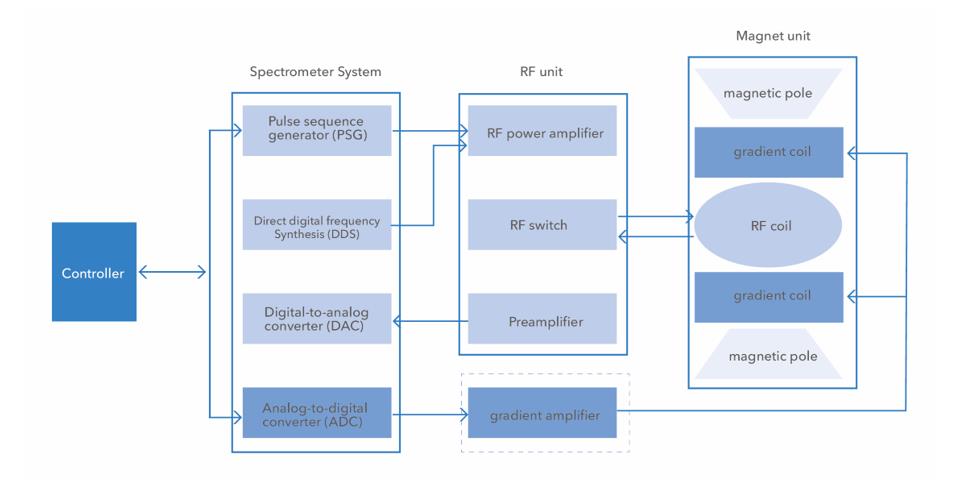

Pulsed NMR also called Time domain NMR or Low field NMR

The purpose of applying an appropriate amount of oil in the fiber production process is to make the fiber antistatic, bundled and smooth, so as to facilitate post-processing. Uneven oiling of fibers will cause quality problems such as uneven evenness and wool. Oiling the fibers too high is a waste of money. In addition, in the production of spandex, the fiber oiling detection is not accurate, and the concentration and use time of the degreasing agent Ccl4 cannot be accurately determined, and Ccl4 is very destructive to spandex, which will make spandex brittle and lose its high elasticity. Therefore, it is necessary to accurately measure the oiling rate of fibers.

Pulsed NMR Method Compare with Extraction Method

The traditional extraction method takes 5 to 6 hours for one measurement, while chemical fiber production is continuous and high-speed production, and problems cannot be controlled in time. At the same time, this method is costly and consumes a lot of reagents and labor. The pulsed NMR method has the advantages of being fast, non-destructive, green, and does not consume chemical reagents. Just take a small amount of fiber and put it in the probe to test, and the result can be obtained in ten seconds. The benefits it brings are:

- The pulsedNMR measurement test is fast;

- The calibration of the pulsedNMR measuring instrument is simple;

- Compared with the traditional method, thepulsedNMR measurement has much better repeatability and reproducibility;

- PulsedNMR measurement can be used for quality inspection and quality control in the industrial production process, saving labor and significantly improving efficiency;

- The pulsedNMR measuring instrument is easy to operate, does not require technical personnel, and is easy to operate by untrained personnel;

- The pulsedNMR measurement function is powerful, suitable for the fluorine content test of fiber and textile products;

- The pulsedNMR measurement has no requirements on the shape of the sample, and the sample can be powder, granule, film or block.

- The pulsedNMR measurement is a non-invasive and non-destructive test, and the same sample can be repeatedly measured as needed;

- The NMR signal of pulsedNMR measurement is generated by all hydrogen nuclei in the entire sample volume, and the test result does not depend on the sample surface or sample color;

- Pulsed NMR measurement can be used for 1H content testing in some raw materials and chemical products;

- PulsedNMR measurement can be used for oil and water content testing in other chemical products;

A

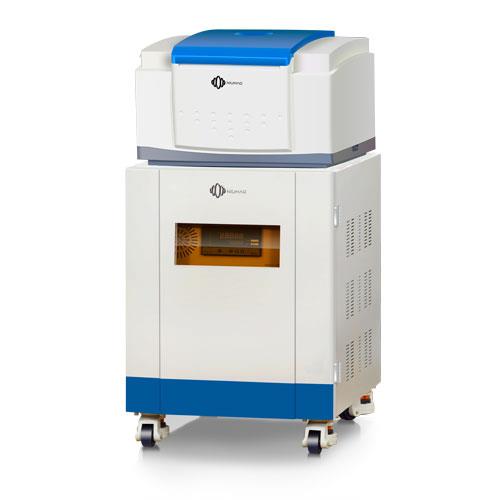

NIUMAG PQ001 Fiber NMR Spin Finish Analyzer

NIUMAG

NIUMAG