Low Field NMR Analysis for Investigating Rubber Crosslinking Density

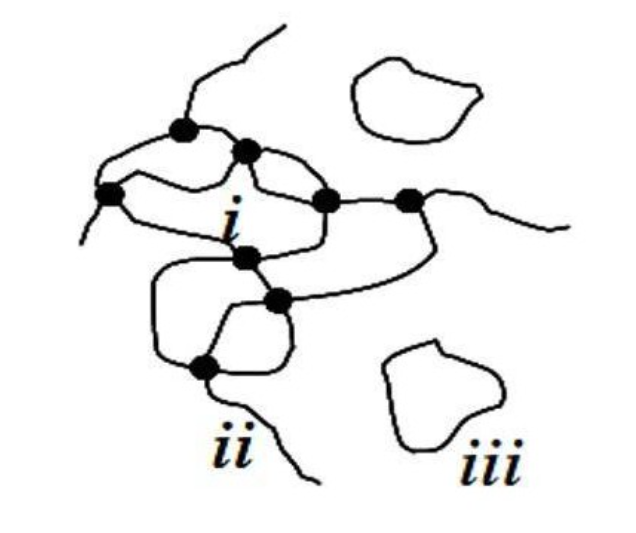

The degree of crosslinking, also known as crosslinking density, is typically quantified in terms of crosslink density, which represents the number-average molecular weight between two adjacent crosslink points or the number of moles of cross-link points per cubic centimeter. Rubber with a lower degree of cross-linking exhibits better elasticity, while rubber with a higher degree of cross-linking tends to have reduced elasticity. As cross-linking intensifies, mechanical strength and hardness increase, eventually leading to a loss of elasticity.

The degree of crosslinking in rubber has long been a challenge in the industry. Conventional swelling methods offer limited testing accuracy and are susceptible to significant human subjectivity. In contrast, the NMR method leverages the changes in the polymer relaxation decay curve with variations in the internal sample components’ state. It employs NMR relaxation technology to swiftly and non-destructively determine the degree of cross-linking by discerning signals from both cross-linked and non-cross-linked chains.

In polymer samples, the solvent component exhibits significant fluidity and slow decay, non-cross-linked segments display some molecular motion characteristics with relatively slower decay, while cross-linked segments are tightly bound, exhibit minimal molecular motion characteristics, and decay faster. Using the innovative MSE-CPMG sequence acquisition, NMR signals are rapidly reversed within the dead time range through combined pulses, preserving the original NMR signal intensity. This approach allows for the collection of shorter relaxation information, further enhancing the accuracy of crosslinking density measurements.

Principle of Low-Field NMR Analysis for Rubber Crosslinking

Low-field NMR analysis technology employs pulses to excite hydrogen protons within material samples, causing them to resonate. Subsequently, after the pulse ceases, hydrogen protons undergo relaxation, with varying relaxation times for hydrogen protons in different states within the sample. The analysis of relaxation signals enables the direct or indirect assessment of material properties. The low-field NMR method utilizes low-field nuclear magnetic resonance analysis to evaluate the movement of hydrogen molecules along the hydrocarbon chain, assessing the sample’s cross-linking degree according to a relaxation analysis model. This testing process eliminates the need for chemicals, is non-destructive to the sample, and offers rapid results, often completing tests within 3 minutes.

Components of a Low-Field NMR Analyzer

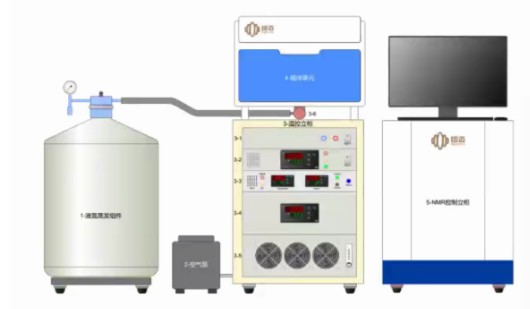

A typical NMR crosslinking density meter comprises several key components:

- Control Unit: This includes the control core and an interface for human-computer interaction.

- Magnet Unit: Responsible for generating radio frequency excitation and collecting signals.

In addition to these core components, the analyzer may include temperature control and a power module, among other features.

NIUMAG VTMR20-010V-I In situ variable temperature NMR Analyzer

NIUMAG

NIUMAG