Hydration of Cement Determine by NMR

Hydration of Cement

The hydration of cement is a chemical process in which cement reacts with water to form a solid, durable material known as hardened cement paste. This process is essential for the development of strength and other desirable properties in concrete.

During hydration, the chemical compounds present in cement, such as tricalcium silicate (C3S) and dicalcium silicate (C2S), react with water to produce calcium silicate hydrates (C-S-H) and calcium hydroxide (CH). The reaction of C3S with water is relatively rapid, while the reaction of C2S is slower but continues for a longer period of time.

The Several Stages of Hydration Process

Induction Period: After the addition of water, there is an initial period where no significant chemical reactions occur. During this time, water is absorbed by the cement particles, and the surface of the particles becomes hydrated.

Initial Hydration: The chemical reactions between cement compounds and water start to take place. C3S reacts with water to form calcium silicate hydrate (C-S-H) gel and calcium hydroxide (CH). The C-S-H gel contributes to the strength and durability of the hardened cement paste.

Acceleration Period: The hydration reactions continue, and the rate of reaction increases. More C-S-H gel and CH are formed, and the paste becomes denser and stronger.

Deceleration Period: The rate of hydration gradually slows down as the available cement compounds are consumed and the reaction products accumulate. The formation of C-S-H gel continues, contributing to the development of strength.

Final Setting and Hardening: The hydration reactions come to completion, and the paste undergoes the final setting and hardening. At this stage, the cement paste gains its desired strength and solidifies into a durable material.

The hydration process is influenced by various factors, including the water-to-cement ratio, temperature, presence of chemical admixtures, and curing conditions. Controlling these factors is important to achieve the desired properties and strength in concrete.

Hydration of Cement Determine Methods

Understanding the hydration process is crucial for concrete production and quality control. Techniques such as calorimetry, X-ray diffraction (XRD), scanning electron microscopy (SEM), and nuclear magnetic resonance (NMR) are commonly used to study and analyze the hydration of cement and its effects on concrete properties.

Hydration of Cement Determine by NMR

In NMR, the principle is based on the behavior of atomic nuclei in a magnetic field. When a sample is subjected to a strong magnetic field and certain radiofrequency pulses, the atomic nuclei absorb and re-emit energy at specific frequencies. This energy absorption and emission can be measured and analyzed to extract information about the sample.

For cement hydration studies, NMR can be used to investigate the water dynamics and hydration products. Cement contains various components such as Portlandite (calcium hydroxide), C-S-H (calcium-silicate-hydrate) gel, and other hydrated phases. The NMR signals from water and the different hydrated phases can be distinguished and monitored over time to understand the progress of the hydration process.

By acquiring NMR spectra at different time points during cement hydration, one can observe changes in the intensity and position of the NMR signals. These changes provide insights into the formation and transformation of different hydrated phases. For example, the disappearance of free water signal and the appearance of signals related to C-S-H gel indicate the progress of cement hydration.

Moreover, NMR can also provide information about the water distribution within the cement matrix. The relaxation times of water molecules in different environments (e.g., bound water, capillary water) can be determined using NMR techniques, which gives insights into the pore structure and the availability of water for hydration.

MRI of Cement

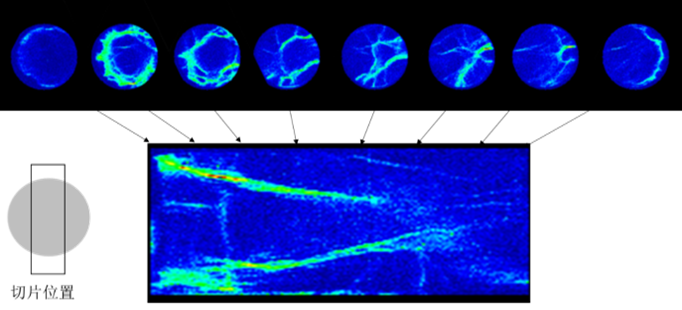

It’s worth noting that NMR studies of cement hydration are typically conducted using specialized NMR instruments and techniques specifically designed for solid samples. These experiments require careful sample preparation, data acquisition, and interpretation. In addition, the NIUMAG NMR instrument can also provide imaging functions. The internal deconstruction and moisture distribution of cement can be seen through MRI imaging, and the hydration process of cement can be studied more intuitively.

NIUMAG Large Size NMR-MacroMR12-150H-I for Hydrogen Cement Analysis

NIUMAG

NIUMAG